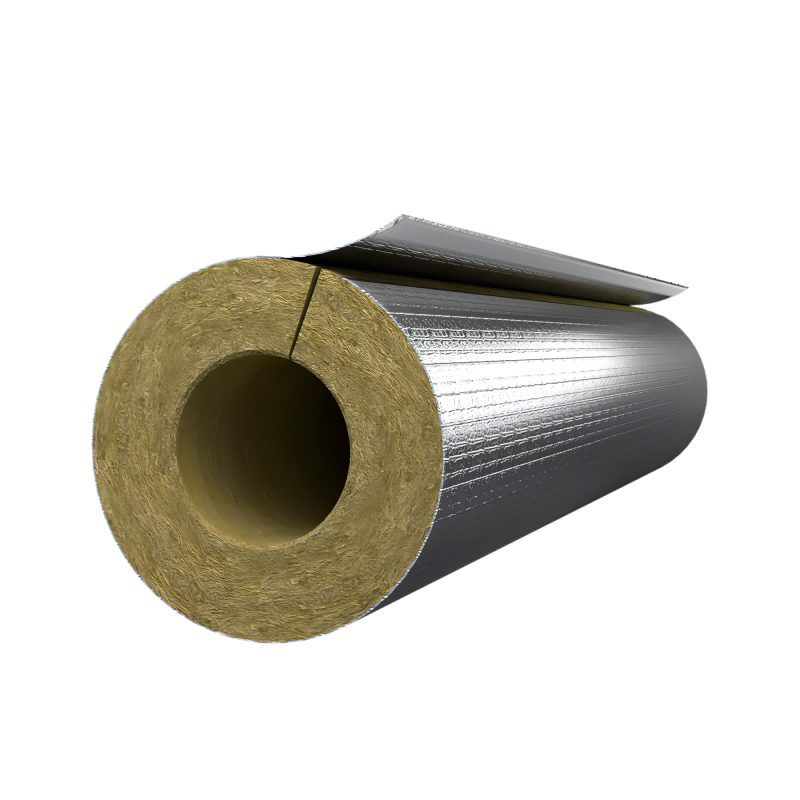

*Noncombustible:

Ecoin Mineral Wool is made from natural rock which has a high melting point (>1000℃)It’s a Grade A1 non-combustible material. In case of fire, it can effectively prevent or isolate fire without the generation of toxic gas. Moreover, it can provide you with more precious time for escape, so as to protect your life and properties.

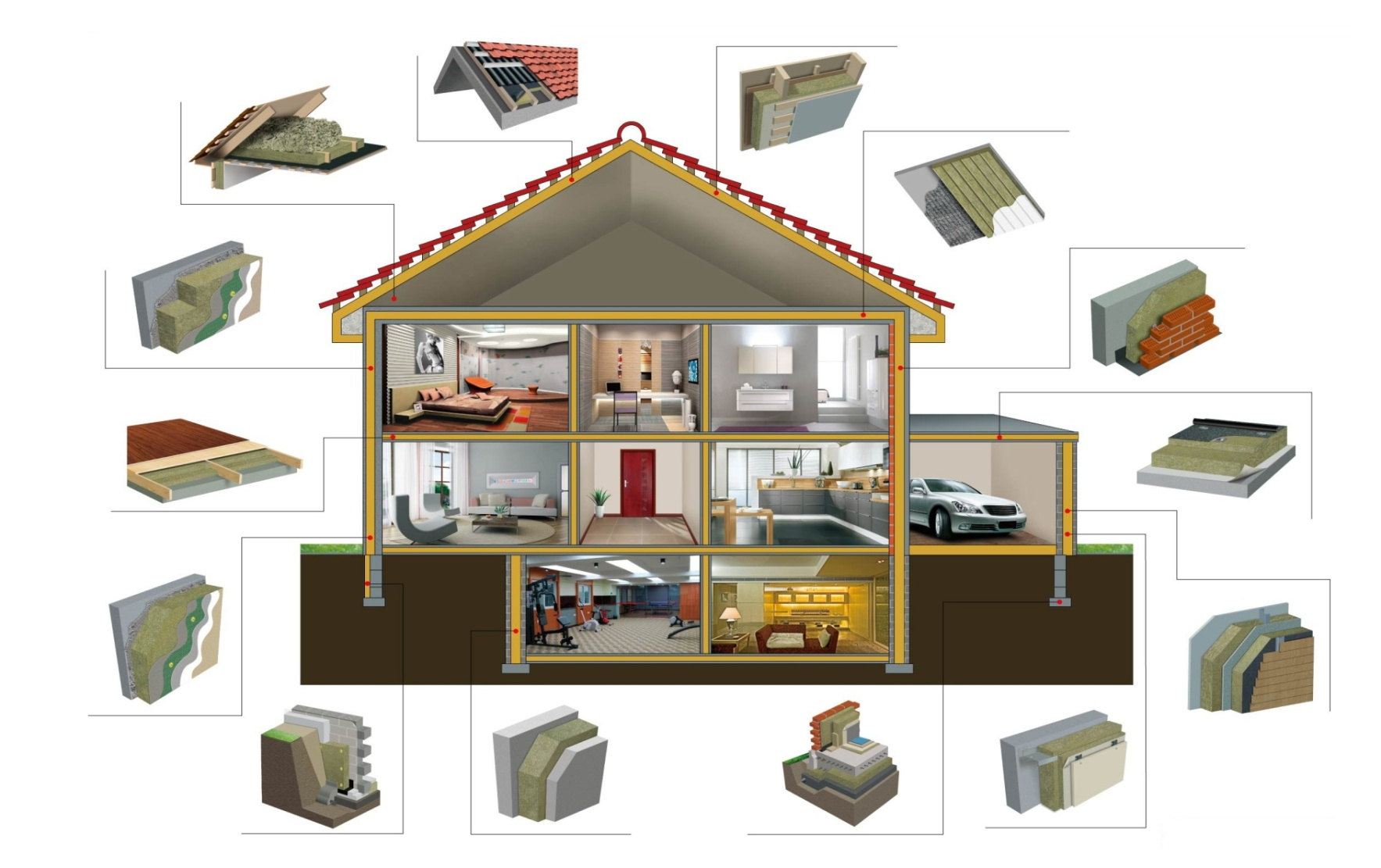

*Thermal Insulation:

Ecoin Mineral Wool has extraordinary thermal insulation performance due to the low shot content as well as lathy and flexible fiber. It can substanially improve the energy utilization of buildings and reduce the energy consumption of air conditioning or heating. Energy consumption can be reduced by 70% if the insulation solution of Ecoin Mineral Wool is adopted. It is the most direct and low-cost method for the emission reduction of greenhouse gases.

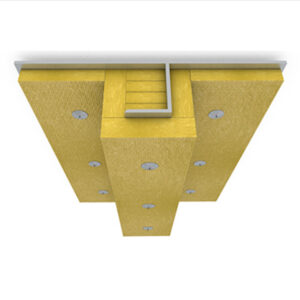

*Sound absorption and noise reduction:

Due to the unique distribution and traits of fibers, Ecoin Mineral Wool contains thousands of micro holes, which can substanially reduce vertical sound waves on walls. Accordingly, Mineral Wool can reduce the interval of sound reflection and can hereby effectively improve the effect of indoor sound insulation.

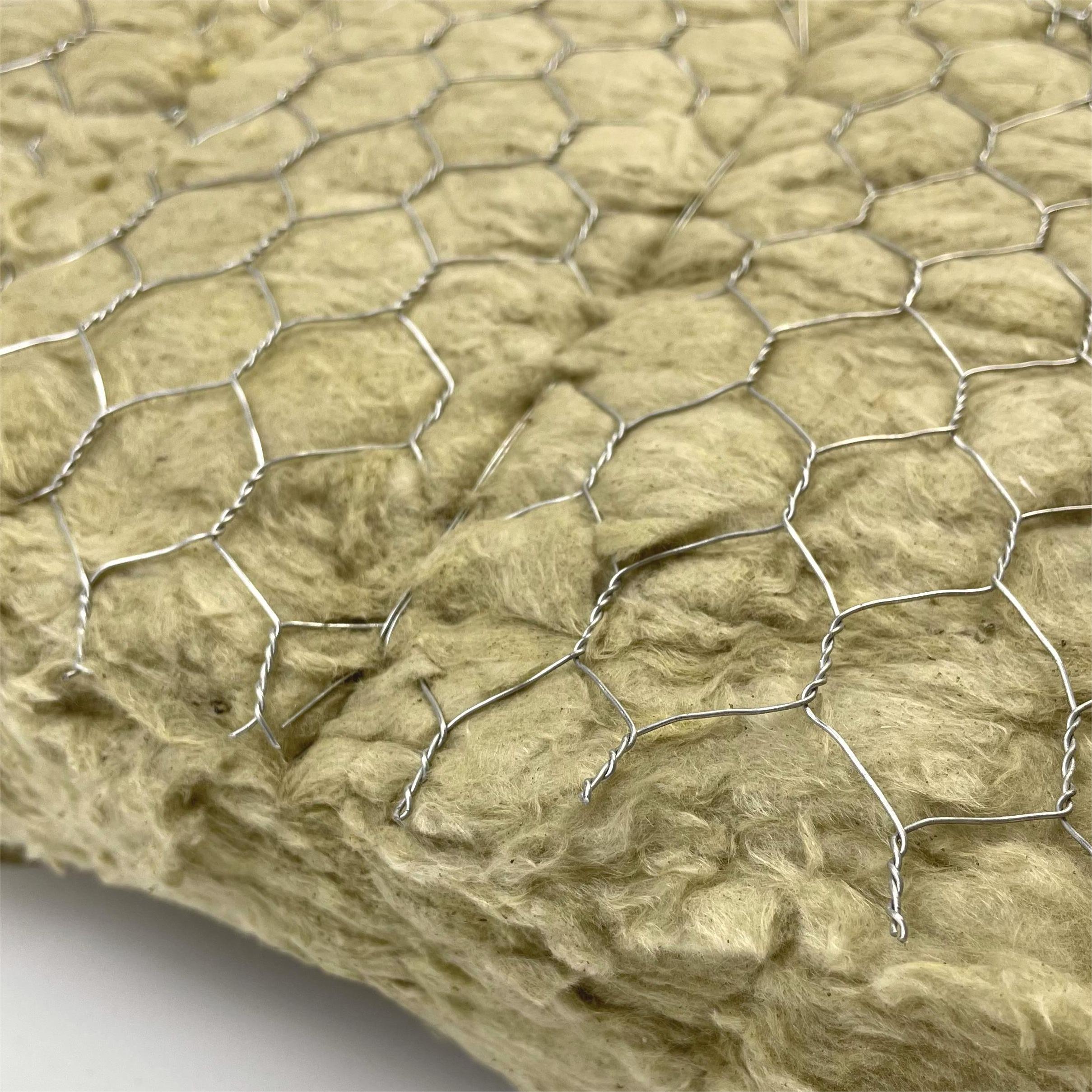

*Water repellence:

Ecoin Mineral Wool has good water resistance, with a water repellence rate of of exceeding 98%. With low water absorption and no capillary percolation, it has good thermal insulation performance. Moreover, with its PH value being neutral or alkalescent, Ecoin Mineral Wool never corrodes metal materials such as carbon steel, aluminum, and copper. It’s an inorganic product, and absolutely resistant to corrosion, molds, softening, and bacteria.

*Good weather ability:

Due to fairly poor water absorption and hygroscopicity, Ecoin Mineral Wool has good dimensional stability and resistance to thermal expansion or shrinkage. As it is inorganic and has inactive chemical elements, it will not change along with the changes in ambient temperature and humidity and is hereby resistant to distortion. Accordingly, the incombustibility, thermal insulation, sound absorption, corrosion resistance, and other properties of Ecoin Mineral Wool will not fail after a long time of utilization.

*Good Safty:

Ecoin Mineral Wool is free of asbestos as well as CFC and HCFC which would destroy the ozonosphere in the atmosphere. It provides no growth environment for microbes and no feed for pests and molds, having the function of preventing insect pests. Using Ecoin Mineral Wool will make buildings safer. (Note: Mineral Wool has been recognized as a non-carcinogenic substance by international cancer research authority.)