1. What’s the Difference Between Ceramic Fiber and Fiberglass?

The ceramic fiber is manufactured by melting varying ratios of aluminum and silicon in an industrial furnace. For this reason, this ceramic fiber is also known as aluminum silicate fiber. After the melting, the mixture goes through either a blowing process or a spinning process: in the blowing process, the melt is made to flow through an aperture at the bottom of the furnace where constant streams of air will cool and separate the molten material into strands or fibers in the spinning process, the melt is dripped from the furnace aperture through arrays of rapidly spinning wheels. Both of these two processes make the fibers into a tough fleecy mass (loose conglomerations).

The history of ceramic wool dates back to the late 1950s when ceramic fiber insulation was originally made from white clay called Kaolin. Up to the 1980s, a boiler manufacturing company discovered that when the clay was heated high enough, it became a liquid and sometimes formed long fibers and small beads, which could be made into a high-temperature insulating material for applications up to 3,000°F. Thus the ceramic wool is also known as ceramic fiber blanket 3000 degrees.

Indeed, this ceramic fiber insulation is an ideal choice for high-temperature applications: generally, this ceramic wool is capable of withstanding temperatures exceeding 1200°C (2192°F). ECOIN offers ceramic fiber blankets with a working temperature of 1260℃-1430℃ and ceramic fiber pipes insulation that withstands temperatures of 1260℃

2. What is the difference between ceramic fiber and fiberglass?

Like fiberglass and rock wool, ceramic fiber is another type of material for insulation. However, between the ceramic fiber insulation and the fiberglass, and between the ceramic wool and the rock wool, there are still some differences.

Both the ceramic wool insulation product and the fiberglass insulation product are refractory materials for thermal insulation. However, their maximum working temperatures are different: as we mentioned before the ceramic blanket of 3000 degrees works under a maximum temperature of 3000°F (above 1600°C); meanwhile, the maximum service temperature of the fiberglass is less than 500°C.

This difference is mainly due to the different compositions of the material and the different production processes:

Fiberglass is mainly made from silica sand, limestone, and dolomite. This insulation performs best in temperatures ranging from 0 to 1000 degrees. On the other hand, ceramic fiber is produced by melting aluminio-silicate materials in a furnace. Compared with fiberglass wool, this ceramic wool insulation is more resistant to thermal shock and often used in higher-temperature involving applications, such as furnace linings, kiln linings, and fire protection.

*Ceramic wool vs Rock wool

Both ceramic wool and rock wool are the most commonly used thermal insulation materials and both of them have a certain thermal insulation effect. It’s easy to distinguish them from their appearance. And there’s also a huge price difference between these two products.

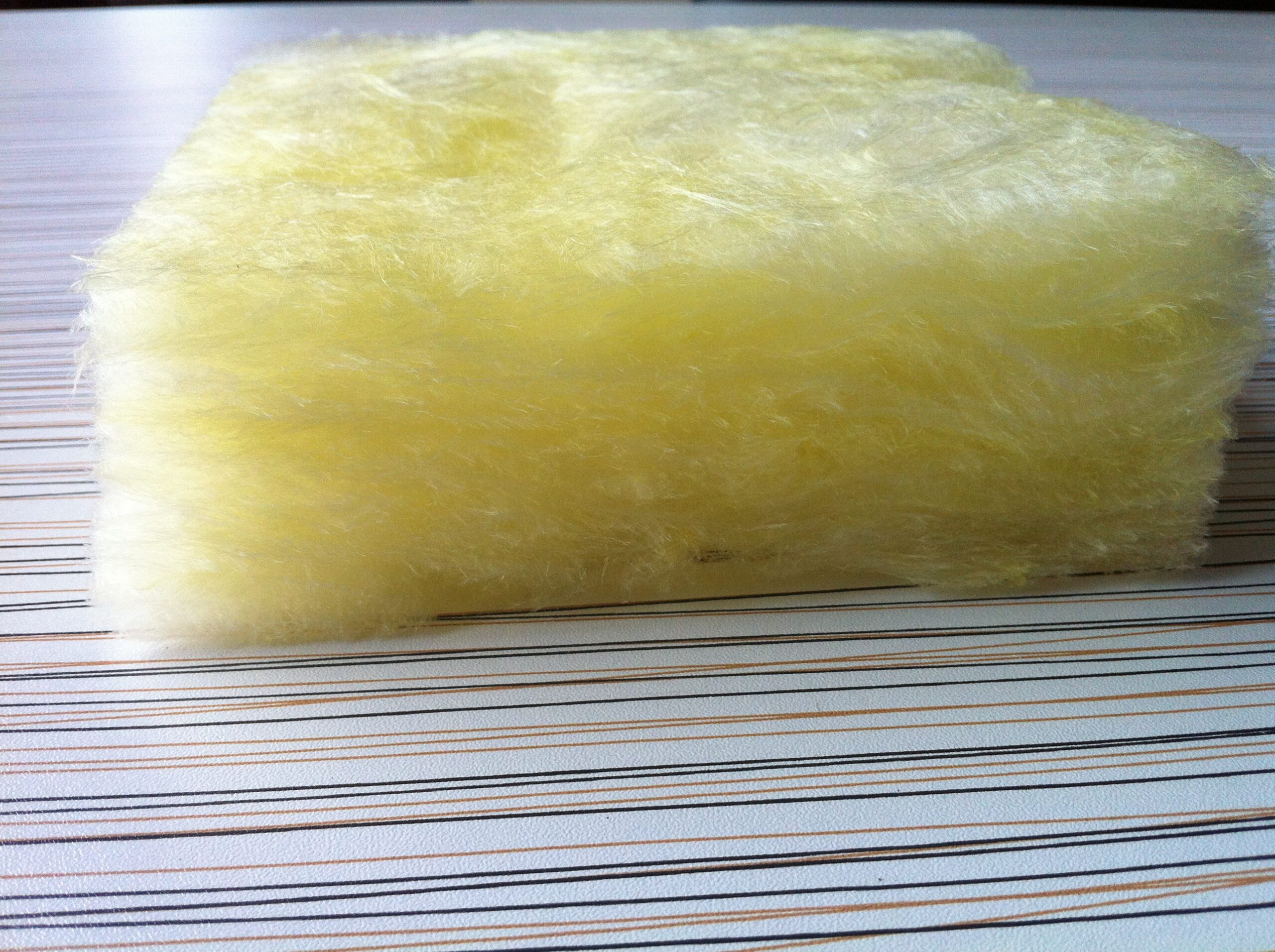

Firstly, the color of rock wool is yellow while the ceramic fiber insulation material is white.

Secondly, the difference in temperature resistance is relatively large, due to which is the large price difference. The rock wool’s working temperature is 650℃ at maximum while the ceramic wool can reach more than 1600°C. However thermal conductivity of ceramic wool is higher than that of rock wool. Generally speaking, rock wool is a kind of thermal insulation material of low-temperature resistance and low thermal conductivity, which makes it a popular option for wall insulation; ceramic wool insulation is a thermal insulation material of high-temperature resistance and relatively higher thermal conductivity, which makes it more appropriate in high-temperature environments for industrial applications.

Besides, rock wool has a better property of water repellency while ceramic wool can’t achieve the waterproof effect. This means that once the ceramic wool insulation material contacts water, it might reduce the thermal insulation effect greatly.

3. Bio Soluble Ceramic Blanket-a safer choice

What is Bio Soluble Ceramic Blanket?

The ceramic fiber blanket is the most common type of the series of ceramic fiber insulation products. And the Bio Soluble Ceramic Blanket can be seen as an upgraded version of this product: it’s manufactured from a blend of high-purity calcium, silica, and magnesium. This modified composition results in a body-soluble fiber with low bio persistence, which makes this ceramic fiber blanket more eco-friendly in comparison to the traditional type.

As an experienced ceramic fiber supplier, ECOIN has always put environmental safety as our priority. And our Bio Soluble Ceramic Blanket is one of our best-selling products. Our Bio Soluble Ceramic Blanket is characterized by a high rate of biodegradation, low hazard classification, and of course, excellent thermal stability and shock resistance.

What are other ceramic wool insulation products that we provide?

Apart from the Bio Soluble Ceramic Blanket, ECOIN also offers other ceramic fiber insulation products: our main products are ceramic fiber insulation blankets and ceramic fiber pipe insulation.

The Ceramic Fiber Blanket is made of Gao-Ling clay, alumina, and silica oxides by a spun or blown process. Its unique interwoven texture requires no more chemical binder and this texture ensures a strong, lightweight, and durable structure for applications at high temperatures.

It’s worth mentioning that this ceramic fiber blanket has high heat resistance, which makes it fireproof. For this reason, this high-temperature blanket is also known as a refractory blanket or refractory ceramic fiber insulation.

ECOIN offers refractory blankets of different densities and different thicknesses ranging from 1″(25mm) to 2″(50mm), among which the ceramic fiber blanket of 50mm is very popular.

The Ceramic Fiber Pipe Insulation material is a tubular or half-tubular ceramic wool product. It’s mainly used for industrial pipe insulation at high temperatures. This Ceramic Fiber Pipe insulation is also known as an aluminum silicate shell.

ECOIN offers Ceramic Fiber Pipe Insulation products in different sizes: with densities of 96-128kg/m3, with diameters ranging from 1/2’’to 24’’, and with different thicknesses.

It is worth mentioning that ECOIN also offers Ceramic Fiber Pipe insulation with foil facing.

4. What is ceramic fiber insulation used for?

Both the ceramic fiber insulation blanket and the ceramic fiber pipe insulation are widely used in industrial applications. To sum up, the main applications for these ceramic wool insulation products are the following:

Power industry

The power industry uses boilers to make steam and heat for electricity generation.

The ceramic fiber insulation materials are mainly used to insulate the superheater tubes, the electric turbines, etc.

In terms of the power industry, it’s worth mentioning that the solar power industry also uses ceramic wool insulation: the solar power industry uses heaters as a backup system when there’s no for generating electricity; the heaters and the tube walls require high-temperature ceramic blanket or ceramic fiber pipe insulation to shield the heat.

Steel and Foundry Industry

The foundry furnaces are lined with brick, and refractory blankets to retain the heat inside the furnace area. This makes ceramic fiber insulation indispensable for the industry and for this reason, ceramic wool is also known as ceramic fiber insulation for forge. These refractory ceramic fiber insulation products are mainly used in coke ovens, blast furnaces, melting furnaces, and other equipment such as electric art or open-hearth, etc.