Insulation material is commonly installed in the building or in the home. Like many other construction materials, it’s important that the insulation material is highly resistant to fire.

However, there’s a difference between fireproof and fire resistance: the concept “fireproof ” leads one to believe that fire cannot touch the material while “fire resistance” indicates that the material can withstand a great deal of fire. Actually, most fireproof insulation is characterized by its long-term endurance to fire: with enough head and a long enough fire, anything will be negatively affected even fireproof insulation.

1. What insulation is fireproof?

At present, the insulation material is focused both on retaining heat and stopping fires. Fireproof insulation material is more and more popular as it doesn’t only protect the integrity of the structure but also guarantees the safety of the personnel inside the building.

The first naturally fireproof insulation was wool. Nowadays a great variety of fireproof insulation materials are developed and widely used in many applications.

Is fiberglass insulation fireproof?

Fiberglass is made from silica sand mixed with limestone and soda ash. Other ingredients such as magnesite or kaolin clay might also be added to improve the fiberglass’s performance. After these ingredients are mixed, they will be heated at a higher temperature so that the glass is molted. And this melted glass will be spun and formed into glass wool.

Thanks to these mineral components, fiberglass insulation isn’t flammable. However, it will melt at a temperature higher than 1000°F (540°C). As most house fires never reach this temperature, fiberglass is considered a type of fireproof insulation.

ECOIN’S fireproof fiberglass insulation is class I fire rating insulation material: this means that our fiberglass material doesn’t catch fire; even if a fire begins under extreme conditions, our fireproof fiberglass insulation will slow the spread of fire (flame spread index >25)

It’s worth mentioning that though fiberglass doesn’t burn, the facing of foil or paper is still flammable. In the case of ECOIN’s foil-faced fiberglass insulation, the fire rating is Class II and its flame spread index is less than 75.

More information about our fireproof fiberglass insulation: Ecoin Fiberglass Insulation

Is mineral wool insulation fireproof?

Compared with fireproof fiberglass insulation, mineral wool insulation is featured even better fire resistance: unlike fiberglass, mineral wool is made out of rock, which is a non-flammable material; mineral wool has a higher melting point, withstanding temperatures up to about 1100°c. In real life, few house fires will top out at 750°c, which means there’s no possibility that mineral wool will burn or even degrade.

As we mentioned above, mineral wool insulation is probably the best fireproof insulation material. If you want to make your house or building as fireproof as possible, this fireproof mineral wool insulation is the best choice as a fire-blocking agent. It’s worth mentioning that, like fiberglass insulation, the facing of mineral wool insulation is flammable.

More information about our fireproof mineral wool insulation: Ecoin Rock Wool

Is foam rubber fireproof?

Foam rubber materials are made from rubbers or elastomers mixed with various chemicals and ingredients. Different types of compounds exhibit different physical and chemical properties and different temperature resistances.

Most silicones have inherently good flame resistance. They are low-smoke materials: when a piece of silicon catches fire, it will give off smoke levels almost the same as cigarette smoke.

Like silicone, EPDM materials also have a good level of flame resistance. In terms of Neoprene, though it’s not considered a fire retardant material, it’s much less flammable than other commercial rubber materials.

ECOIN’s fireproof foam rubber insulation is mainly made from EPDM or Neoprene: thanks to its self-distinguishing ability, it doesn’t catch fire easily and its flame spread index is less than 25, which makes it class I fire rating insulation. Recently our fireproof foam rubber insulation has just passed the test of standards ASTM D635 and ASTM E84.

More information of our fireproof foam rubber insulation: Ecoin Rubber Foam

Refractory ceramic wool

Ceramic fiber blanket is well known as a refractory blanket: its main component is aluminum silicate. The refractory ceramic fiber blanket is made of fibers formed by needle punching. It has a certain strength. Like fireproof mineral wool, this refractory ceramic wool is made of stone. For this reason, its fire resistance is the same as that of sone and this refractory ceramic wool doesn’t catch fire.

ECOIN’s refractory ceramic fiber blanket is resistant to a high temperatures above 1000 ℃. It’s mainly used in high-temperature industrial kilns and furnaces, fire insulation of high-temperature pipelines, etc.

More information for our refractory ceramic fiber blanket: Ecoin ceramic fiber

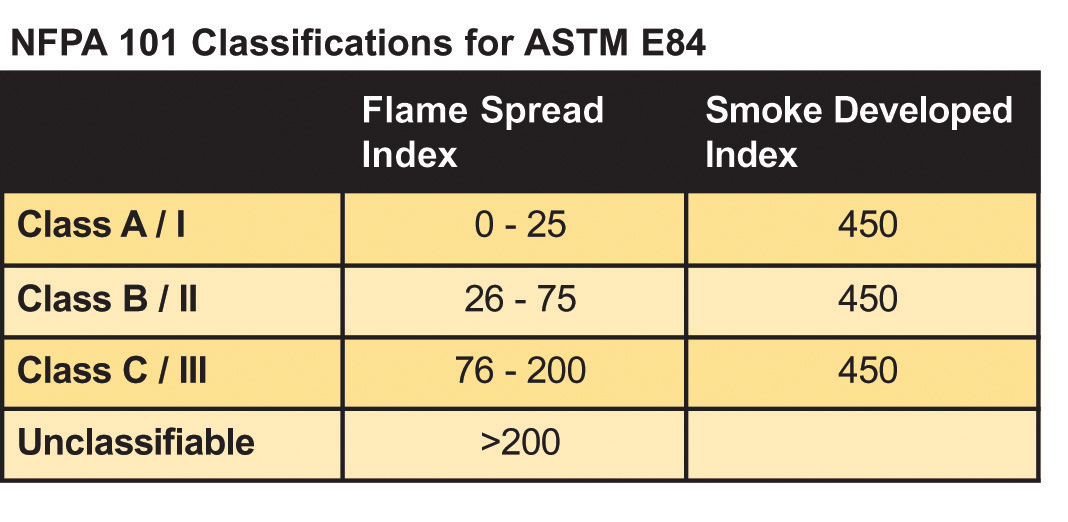

2. What is the fire rating for insulation?

As we mentioned above, Fire Rating is an important parameter to measure the fire resistance of insulation material: many factors are taken into account, such as ignition temperature, flame spread, and smoke toxicity, etc. These are a series of numerical indicators of how the materials will respond when exposed to fire. And based on these values, different classifications of fire-resistance rating are established by classifying materials by their ability to support and propagate fire. These fire rating classifications guide us during the selection of fireproof insulation materials.

Among so many indicators, the flame spread index is the most important: it describes the surface-building characteristics of the material. More specifically, this value is obtained by a ten-minute tunnel text: the best-known test is the American Society for Texting and Materials (ASTM) Test Method E-84, commonly known as the tunnel test. This test measures how far and how fast flames spread across the surface of the text sample. The resulting flame spread index is expressed as a number on a continuous scale where the cement board has a value of 0 and red oak has a value of 100. This scale then is divided into three classes, which are the most commonly used fire rating classifications:

Class I Fire Rating

Class I fire-rating insulation is also known as class A fire-rating insulation. Normally, class I fire rating is the best fire resistance rating the material can achieve. Class I fire rating indicates that the flame spread index of the material is between 0 and 25.

Most of ECOIN’s fireproof insulation is class 1 fire rating insulation, which means that our insulation materials do not burn well and are very unlikely to contribute fuel to a fire.

Class II Fire Rating

Calss II fire rating, or class B fire rating is the next best rating on the list. The flame spread index of class 2 fire rating insulation usually falls between 26 and 75. This rating mainly indicates that the spread of the flame is relatively low.

As we mentioned before, the facings of the fiberglass insulation or the mineral wool are flammable. And for these materials, the fire rating is class II.

Class III Fire Rating

Class III fire rating or class C fire rating shows the least fire resistance that a material has. In other words, materials of class III fire rating has no property of fireproof. And its flame spread is between 76 and 200.

Class 0 Fire Rating

The concept of “class 0 fire rating” is more and more mentioned. Class 0 fire rating is even used interchangeably with class 1 fire rating. They are very similar. However, class 0 fire rating is an improvement of class 1 fire rating.

The class 0 fire rating insulation must first conform to class 1. And it must also have a coating that doesn’t’ add fuel to fires.

3. How to choose the best fireproof insulation materials?

As a professional fireproof insulation supplier, ECOIN offers you fireproof insulation of different materials and in different forms. How to choose the best fireproof insulation material? The fire class rating isn’t the only factor to consider, and many other factors should be taken into account:

Thermal insulation performance– Remember that the key factor of thermal insulation material is its insulation performance. You can’t choose foam rubber for your industrial furnace as it can’t withstand the high temperature as ceramic wool does.

Cost efficiency- The price always plays a key role in the selection. Though ceramic wool offers the best insulation performance, it’s not recommended to insulate your home with a ceramic fiber blanket. The price is too high. With fiberglass insulation at a much lower price, you can achieve your goal by insulating your house.

Easy installation- If you work on your own and don’t have a professional team to support you, it’s not recommended to choose insulation materials that require special tools, such as glass wool insulation, etc.