Generally thermal insulation material has two applications: insulation for construction works (including insulation for home and commercial buildings) and industrial insulation. As industrialization is rapidly developing all over the world, industrial insulation occupies a large market share.

1. What is industrial thermal insulation?

Industrial thermal insulation is essential for the industry: it increases production reliability, guarantees personnel safety, and reduces energy consumption and CO2 emissions.

Due to the development in this area, industrial insulations have become multifunctional: they offer accurate temperature control, reduce heat loss, and they are also soundproof and fire-resistant. Industrial insulation is widely used in industrial furnaces, ovens, water heaters, heating systems, and air conditioning equipment. It’s worth mentioning that industrial insulation is also used in perishable cargo, protecting the goods from high temperatures.

Nowadays, the new trend of industrial insulation is being cost-effective, lightweight, and space-saving. Industrial insulation of high quality will make your operations more efficient and safer, and will improve the quality of your output.

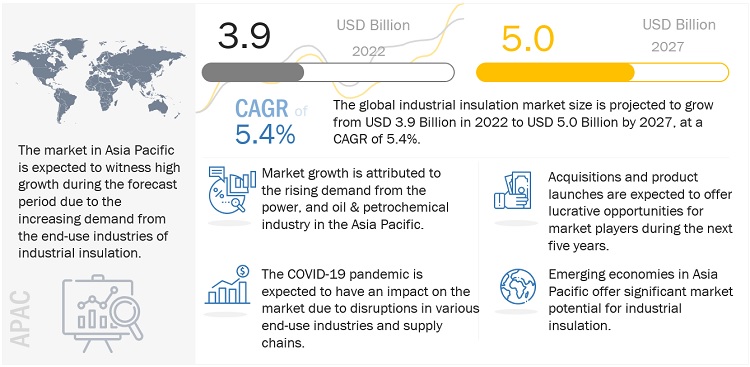

2. How is the industrial thermal insulation market in the future?

Challenges of the industrial insulation market

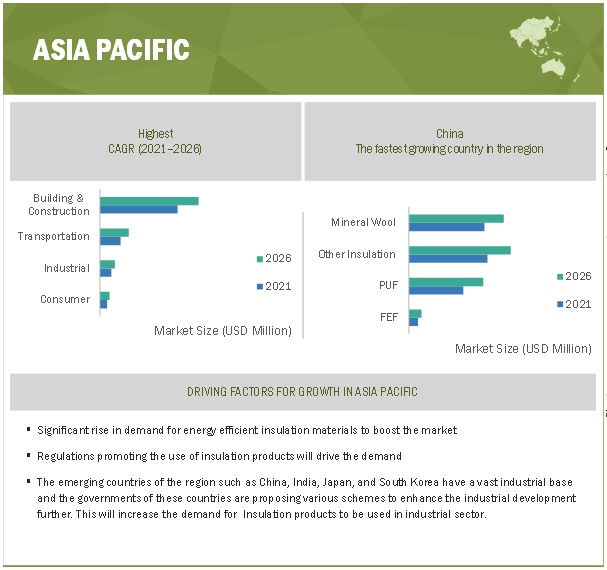

In the past few years, many new challenges have emerged in the industry and the pandemic has been the biggest one: many countries had to impose lockdown to fight against the virus, which inevitably disrupted the pace of manufacturing and the supply chain. Particularly in countries of Asia Pacific, such as China, Japan, and India, the lockdown forced them to decrease their production of industrial insulation, which occupies a major market share.

Besides, the fluctuation in the availability and pricing of crude oil is another great challenge: many types of industrial insulation products are derivatives of crude oil, such as foam rubber, etc.; and the fluctuation of the oil’s pricing had a notable effect on the cost of raw material for industrial insulation. Since February 2022, the Russia-Ukraine war has risen uncertainty in the global market, including the industrial insulation market.

Opportunities of the industrial insulation market

Though the industrial insulation market has experienced challenges and declines in the past years, there are still many opportunities in the future: the growing industrialization across developing economies drives the market most; in emerging economies such as China, India, Malaysia, and Vietnam, the urbanization and industrialization are still growing rapidly and the demand of industrial insulation is estimated to increase at a rapid pace.

Moreover, in many developed countries, the growing adoption of industrial automation industry also drives the industrial insulation market: the use of industrial thermal insulation in the automated machine improves the equipment’s performance and extends its service life.

Future of the industrial insulation market

The industrial insulation market is projected to reach 5.0 billion by 2027. How to seize the most market share? The keys are the following:

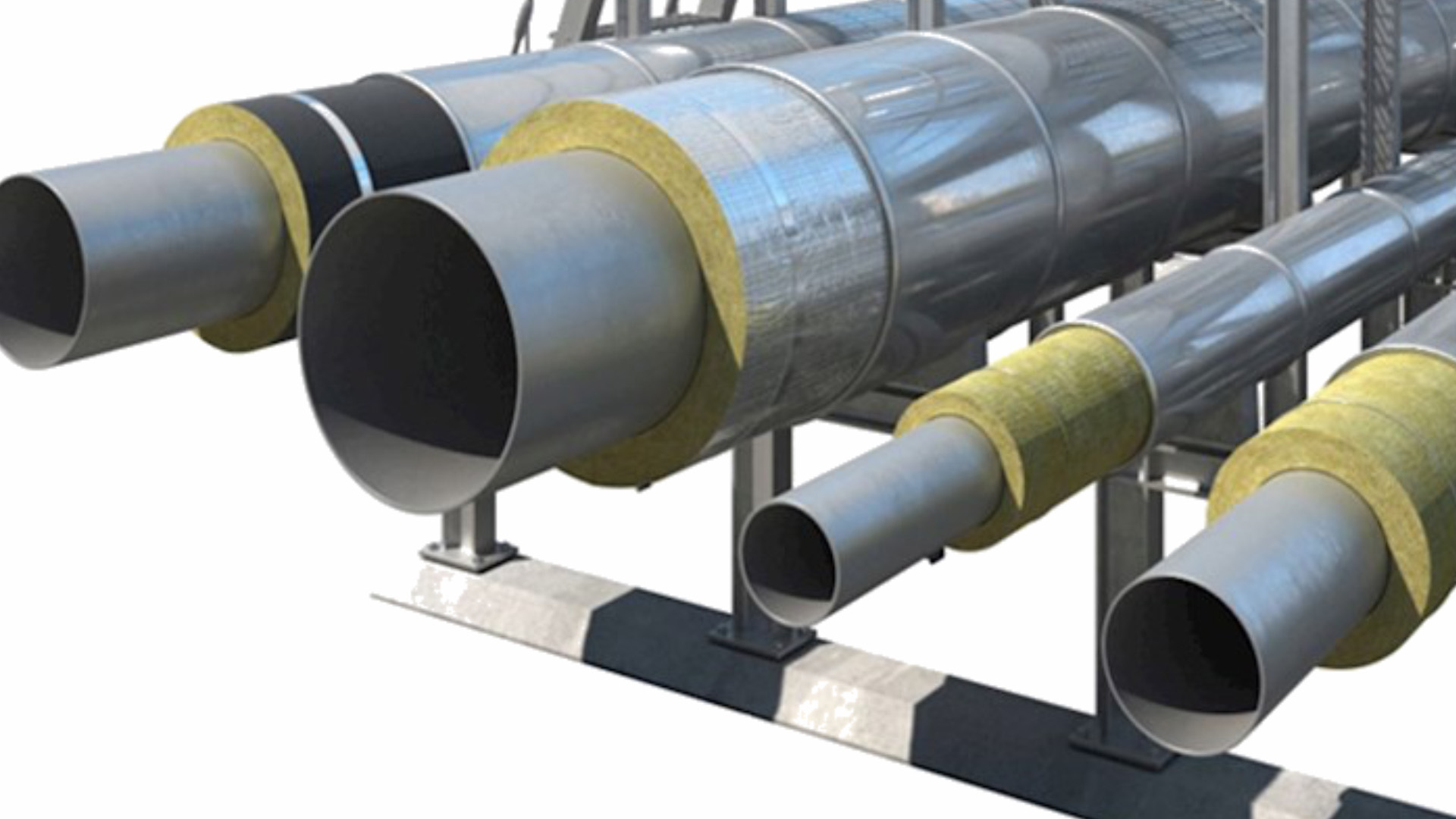

The fastest growing form of industrial insulation-Pipe insulation is the most widely used insulation product in industrial manufacturing. It’s necessary for almost all kinds of heavy industries: in power plants, the pipe insulation helps to carry superheated steam and feed water; in the petrochemical industry, the pipe insulation helps to maintain the required temperature of fluids and gas.

The fastest growing insulation material-The mineral wool segment will be the highest revenue contributor to the industrial insulation market. As we mentioned above, pipe insulation occupies the major market share and most of these products are rockwool pipes. Besides, this rock wool pipe insulation is made from rock materials, which indicates no independence on crude oil.

The fastest growing region in the insulation market-The Asia Pacific will be the highest revenue region in the industrial insulation market. As we mentioned before, industrialization and urbanization will keep growing in this area and consequently, the demand for industrial insulation will keep growing in very industrial sectors, such as oil and petrochemical, gas for power, etc.

3. Main applications of industrial insulation

In the industry, there are many types of equipment or worksurfaces that have special temperature requirements to ensure efficient operations. This is where industrial insulation is needed:

Heating equipment-heaters, boilers, turbines, covers of motors and heat exchangers, etc.

Process equipment with high surface temperatures-melting and drying furnaces, formators, autoclaves, and waste heat recovery units, etc.

Process equipment in contact with cold liquids and gases-water tanks or tanks with liquefied gas, filters, refrigerators, and freezers.

Generally speaking, industrial insulation is commonly used in iron/steel making and other kinds of industrial furnaces: industrial insulation helps to maintain a homogeneous temperature in the furnace; its reduced weight and compact size also allow for more available space in the furnace.

To sum up, effective industrial insulation plays a key role in the industrial process: it maintains the temperature limit and reduces heat loss; it also protects working staff from contact injuries and reduces environmental impact including CO2 emissions.

As a professional thermal industrial insulation manufacturer, ECOIN offers industrial insulation that helps to minimize costs and maximizes the capacity and service life of the equipment. ECOIN’s industrial insulation mainly are the following:

Rockwool pipe insulation, also known as mineral wool pipe insulation, is designed to cover pipes in both commercial and industrial applications: for HVAC systems in commercial buildings, rockwool pipe insulation helps to reduce energy loss; for industrial piping systems, rockwool pipe insulation helps to maintain the required temperature.

For industrial insulation, rockwool pipes are required for different performances keeping water hot or cold:

Warm water transportation-when water travels between a boiler or heating system to central heating units, the rockwool pipe prevents heat loss during the transportation.

Cold water transportation- the rockwool pipe keeps the temperature low, ensuring the water is delivered at its required temperature.

Rain/wastewater transportation-rockwool pipe insulation is required to avoid water heating up.

ECOIN’s rockwool pipe insulation material is made from natural rock and has a high melting point (>1000 ℃). Our rockwool pipe can be used under a temperature of up to 650°

Aluminum cladding for pipe insulation

Aluminum cladding for pipe insulation is necessary as it offers a protective outer surface for industrial insulation systems. It helps to protect the interior insulation material (for example, rockwool pipe) and underlying pipes from physical damage, UV exposure, water, and other corrosive environments. In summary, this aluminum cladding for pipe insulation has five main functions: weather barrier, vapor retarder, mechanical abuse covering, appearance covering, and hygienic covering.

When selecting aluminum jacket for pipe insulation, one must consider the thermal, mechanical, chemical, moisture conditions, cost, and aesthetics requirements. ECOIN offers different types of aluminum jackets for pipe insulation. Our main products are aluminum and stainless-steel cladding for pipe insulation.

Aluminum jacket for pipe insulation–The biggest advantage of aluminum sheet is its light weight. It also has a certain level of resistance against corrosion. But this aluminum jacket for pipe insulation has poor durability when exposed to heat.

ECOIN’s aluminum cladding includes smooth, embossed, and corrugated surface types: the smooth type is more attractive and easier to clean, but it shows surface wear; the embossed type doesn’t show surface damage but it holds contamination easily; the corrugated type is the stiffest kind but it may collect water on the top surface.

As we mentioned before, all the mechanical and chemical factors must be taken into account in order to choose the most suitable type.

Stainless steel jacket for pipe insulation: Compared with aluminum sheet, stainless steel has a much higher melting point and lasts longer when exposed to heat. Besides, stainless steel sheet is highly carrion-resistance and widely used in chemical plants.

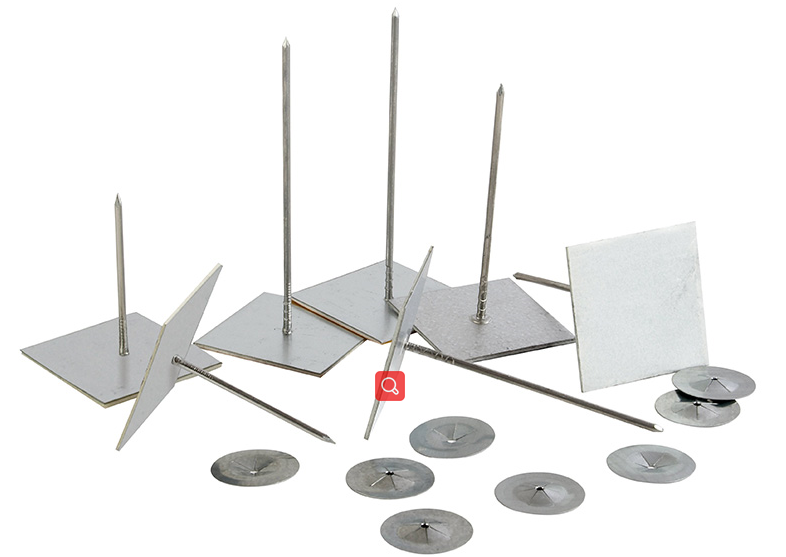

For insulation jacketing, pipe insulation pins and other accessories are indispensable (To know more about insulation accessories, click Types of Insulation Accessories and Where to Use Them ).

ECOIN offers different types of pipe insulation pins, including perforated type, self-adhesive type, and weld pins for insulation, etc.

For more information, please click: Ecoin Galvanized Insulation Pins

Ceramic fiber insulation for forge

The ceramic fiber blanket is the best option for industrial applications at high temperatures: our ceramic fiber blanket works at a maximum temperature of 1430 ℃ and is completely resistant to any kind of thermal shock. Our ceramic fiber blanket is widely used for furnaces, boilers, nuclear insulation, and high-temperature pipe insulations.

It’s worth mentioning that ECOIN’s ceramic fiber blankets are produced from high-strength sun fibers providing the best handling strength. ECOIN offers a great variety in density, including 64kg/m3, 96kg/m3, 128kg/m3, etc.