Ⅰ. What is the moisture barrier on metal jacketing?

In the industrial industry, corrosion is a common issue that affects not only pipes, but also the interior surface of the metal jacketing. Corrosion Under Insulation (CUI) is a hidden danger that should not be overlooked: when water is present in a jacketed insulation system and touches the interior surface of the metal jacketing, corrosion can and does occur. (To know more about CUI, please click: HOW TO PREVENT CORROSION UNDER INSULATION? )

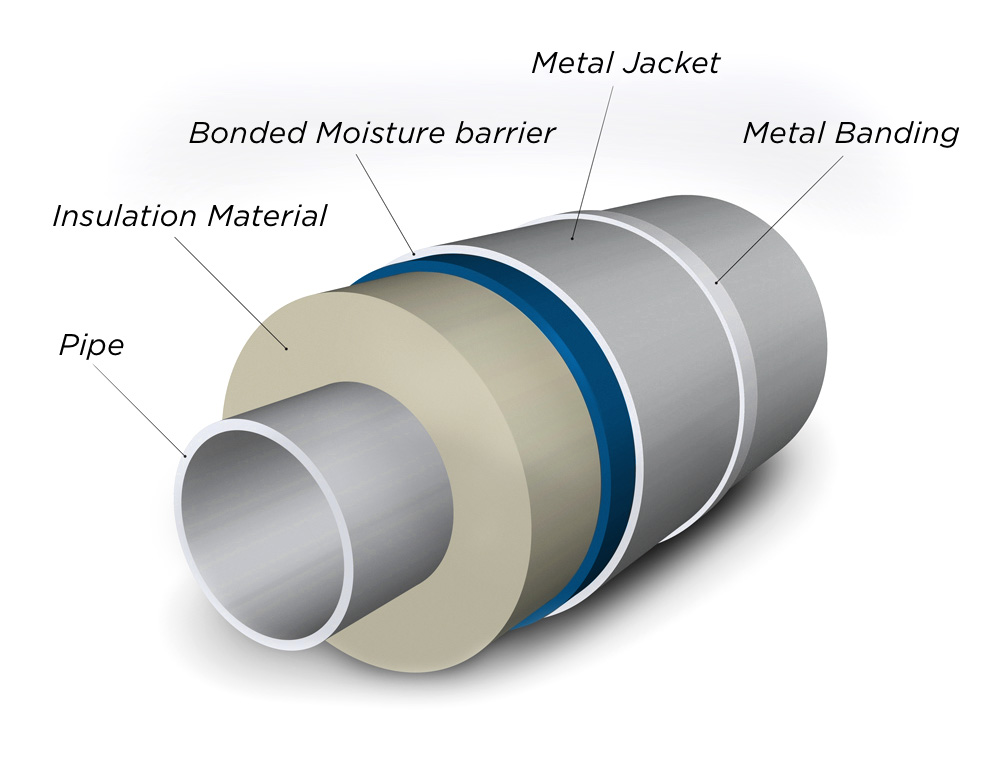

To prevent this corrosion under insulation, an insulation moisture barrier is a necessary coating to protect the underside of aluminum jacketing. It prevents moisture contact with the underside of the metal jacket and helps to isolate it from other insulation layers. This is an important component in all insulation systems (particularly in piping systems ), regardless of whether the application is hot or cold (cryogenic). The aluminum jacketing with a moisture barrier serves as a shield and is key to creating a reliable and long-lasting insulation system.

Ⅱ. Main types of moisture barrier on metal jacketing

Generally speaking, the main types of an insulation moisture barrier on metal jacketing are the following:

1. Polysurlyn moisture barrier

Polysurlyn moisture barrier (also known as PSMB) is a type of polyfilm moisture barrier. Gnerally speaking, it’s usually made of 3 layers at least: a layer of polyethylene, a layer of aluminum foil, and a layer of polysurlyn, When applied to aluminum jacketing, the aluminum foil layer acts as the vapor barrier and it is further reinforced by the polyethylene layer and polysurlyn layer to provide additional durability and protect against punctures or tears. With a total film thickness of 3 mils (76 μm), PSMB is heat laminated in the factory to the interior surface of aluminum jacketing to provide effective protection against moisture.

The main advantages of PSMB are the following:

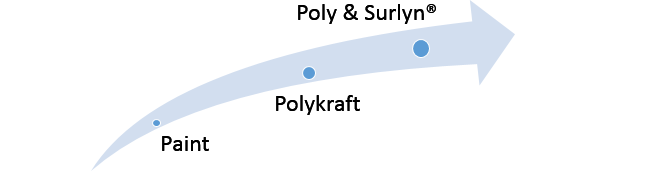

*PSMB is multiple-layers structure: While paint and polykraft are both one layer thick, PSMB consists of at least three layers of separate materials. Thanks to its triple-layer structure, PSMB is considerably more scratch-resistant than the moisture barrier of paint or polykraft. For industrial applications where materials must be robust and long-lasting, this scratch-resistant surface of PSMB is a mission-critical feature that not only protects the metal jacketing system but also ensures its longevity.

In particular, ECOIN offers aluminum jacketing with PSMB of 5 layers: one layer of aluminum sheet as base metal, one layer of Dupont surlyn, on the layer of PE film, on the layer of color coating and one layer of UV protection film. For more information, please click: Ecoin Aluminum Roll With Pplysurlyn

*Zero pinholes:Thanks to this multiple-layer structure, PSMB has zero pinholes. This drastically reduces the ability for water to come into contact with the interior surface of the metal jacketing and cause corrosion. PSMB ensures that water is completely sealed off from the interior, providing superior protection from corrosion.

*Low water-vapor transmission rate: Compared to the polykraft moisture barrier which has a WVTR of approximately 1, polysurlyn moisture barrier features a low water-vapor transmission rate (WVTR) of <0.05, Additionally, PSMB does not have the potential to absorb water like polykraft as there is no paper in its construction.

2. Polykraft moisture barrier

Polykraft moisture barrier is yellow on the surface and looks similar to a kraft paper, However, Polykraft Moisture Barrier (PKMB) is not simply a kraft paper: it consists of one to three mil thick kraft paper laminated with a low-density polyethylene film bonded to its interior and exterior surface. This unique combination provides effective protection against moisture, dust, and other corrosive elements.

The main advantages of PKMB are the following:

*Cost effective-Compared with jacketing with polysurlyn moisture barrier, the cost of PKMB is relatively lower, which offers an economic option for insulation projects in general industries.

*Easy fabrication & installation-Mainly there a are two ways of bonding, the glue adhesion or the heat adhesive laminating. The glue adhesion ensures a low cost and timely delivery of the aluminum jacketing with moisture barrier; on the other hand, the heat lamination enhances the bonding between kraft paper and aluminum coil.

As a professional aluminum coil manufacture, ECOIN mainly provides aluminum jacketing with polykraft moisture barrier laminated on the sheet by heating. For more information, please click: Ecoin Aluminum with Polycraft Moisture Barrier

3. Paint moisture barrier

Painted Aluminum Roll Jacketing is also a great choice when looking for a protective moisture barrier that provides improved aesthetics, color-coding, increased emittance and superior corrosion protection. With a factory-applied, baked-on finish of highly durable hard film acrylic or polyester paint on the exterior surface, this aluminum jacketing resists oxidation, water and fingerprint staining, and the effects of various corrosive environments.

The main advantages of paint moisture barrier are the following:

*Acrylic paint-Acrylic paint is known for its durability and longevity, making it a great choice for the industrial projects that needs to last. It’s worth mentioning that the acrylic paint is highly resistant to water or vapor, making it an excellent choice for outdoor projects. It also offers excellent UV protection and can last a lifetime without fading.

*Polyester paint-Polyester paint is highly resistant to scratches and scuffs. Compared with other types of paint, the polyester paint is a more cost-effective paint solution. It’s worth mentioning that the polyester paint is environment-friendly and contains low VOCs.

As a professional aluminum coil manufacturer, ECOIN offers aluminum jacketing with paint moisture barriers in different colors. For more information, please click: Ecoin Painted Aluminum Sheet

III. What’s the difference between moisture barrier and vapor retarder?

1. Moisture barrier

A moisture barrier is a protective layer that is applied to the interior surface of metal jacketing to prevent corrosion and galvanic corrosion. It is designed to be water-resistant, continuous, tough, scratch-resistant, and durable, making it an effective shield against water damage.

The performance of a moisture barrier is measured by its water vapor transmission rate (WVTR). This rating system is based on the permeability and permeance of the material. The lower the perm rating, the more difficult it is for water vapor to pass through, making it an effective barrier. Conversely, the higher the perm rating, the faster water vapor will pass through.

The key properties of the moisture barrier are the following:

| Property | Polysurlyn | Polykraft | Paint |

| Structure | 3 layer of polymer film | 1 layer of PE film with kraft paper backing | 1 layer |

| WVTR (water vapor transmission rate) | < 0.05 | About 1.0 | Unknown |

However, this doesn’t meant that the moisture barrier with the lowest WVTR is necessarily the best choice for your project. To choose the most appropriate moisture barrier means to choose the most cost-effective type according to the demands of your own insulation project.

2.Vapor retarder

Unlike the moisture barrier, a vapor retarder is applied to the outer surface of insulation materials: it works by preventing the transmission of water vapor from warm and humid areas into the colder pipes of the insulation system. Vapor retarders can be applied either at the factory level or in the field.