1. What is metal jacketing?

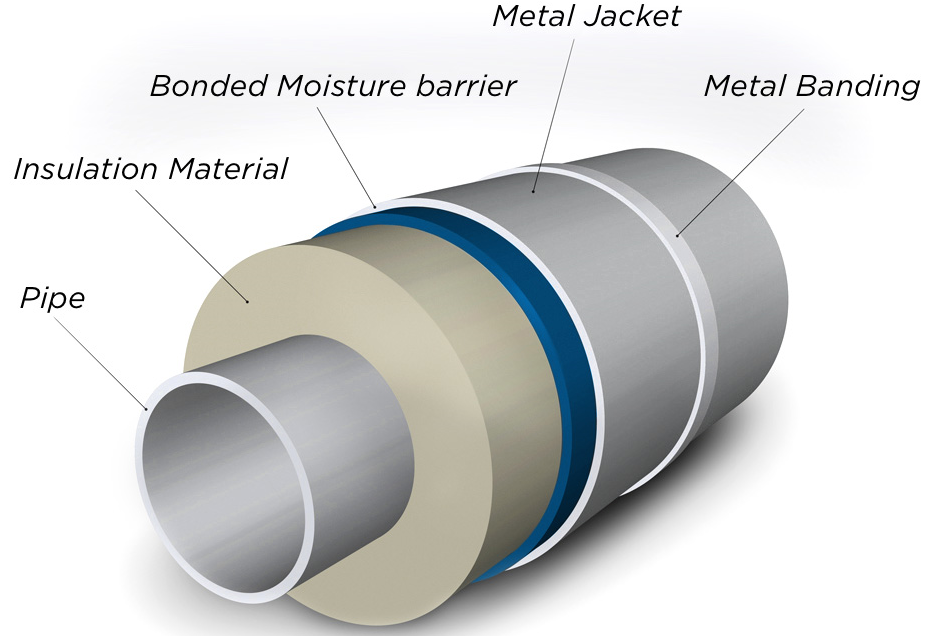

The metal jacketing is an outer cover for the insulation material preventing the thermal insulation material from moisture, wear, chemical damage, and more importantly, corrosion under the insulation. The corrosion under insulation (CUI) is the key factor of using metal jacketing: this metal jacketing, wrapped around the insulation material, serves as a protective layer to prevent moisture ingress.

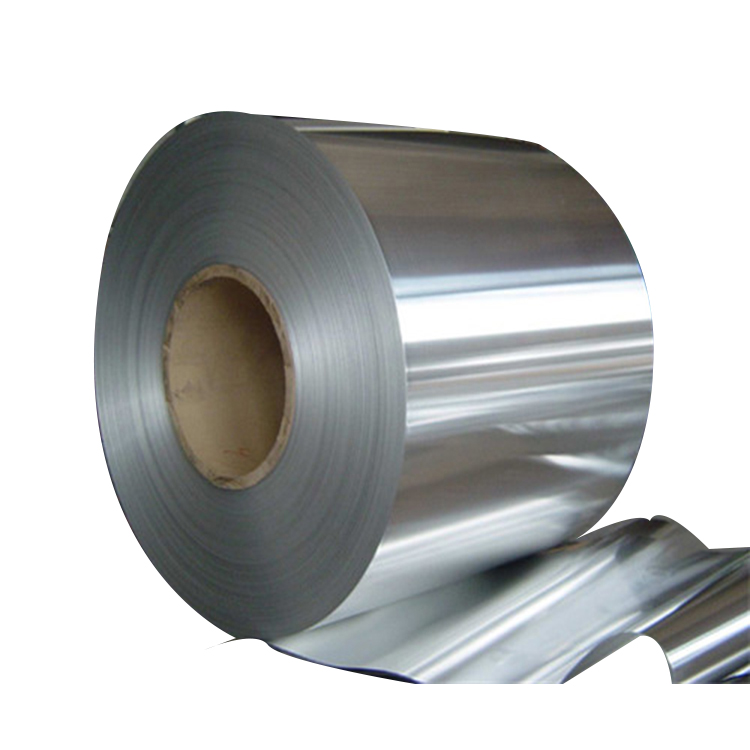

The base material of the metal jacketing generally is aluminum or stainless steel, which is characterized by anti-corrosive properties. This aluminum jacketing or stainless-steel jacketing can be supplied in sheets, coils, or in roll-formed sheets to clad equipment such as ducts, boilers, tanks, vessels, etc. Both the aluminum jacketing and the stainless-steel jacketing are available for further fabrication, such as embossed patterns, etc.

In summary, metal jacketing is an optimal solution for industrial insulation jacketing, cladding of lagging pipelines, and other kinds of equipment.

2. Main types of metal jacketing

As we mentioned before, aluminum jacketing and stainless-steel jacketing are the main types of metal jacketing.

(1). Aluminum Jacketing: Aluminum is the most popular material for metal jacketing. It has many advantages, such as being lightweight, having excellent corrosion resistance, etc. The main types of aluminum jacketing are the following:

Smooth Aluminum Roll Jacketing–This kind of aluminum jacketing for insulation is characterized by a smooth finish, which is more attractive and easier to clean. This smooth aluminum roll jacketing is the primary protective cover for most mechanical insulation systems, including pipes, tanks, and vessels, etc.

Stucco Embossed Aluminum Sheet–This is a type of sheeting with a textured surface, such as a basket weave or a crocodile skin pattern. These textures help hide imperfections and allow the aluminum jacketing to reflect light better. This makes the stucco embossed aluminum sheet more resistant to abrasions than the smooth types. However, this embossed aluminum sheet holds contamination easier than the smooth one.

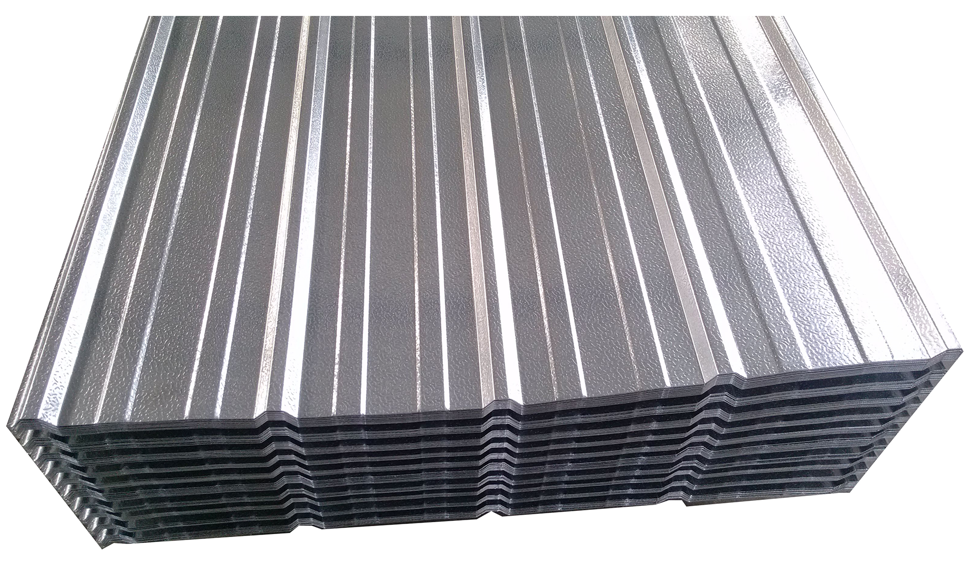

Corrugated Aluminum Sheet– It’s a type of aluminum sheeting that has been pressed to create a ribbed pattern. This design makes the corrugated aluminum sheet much stiffer than other aluminum jacketing for insulation. However, these grooves on the aluminum sheet also collect the water on the top surface which can then penetrate into the insulation.

It’s worth mentioning that the corrugated aluminum sheets are available with bare or painted exterior surfaces, and also available in smooth or stucco embossed surface finishes.

Aluminum Jacketing with Moisture Barrier–This kind of aluminum jacketing is featured moisture barriers laminated to the metal. This moisture barrier helps to prevent galvanic corrosion of the cladding and also corrosion under insulation from underneath.

Basically, we offer two types of aluminum jacketing with moisture barrier: the Aluminum Roll with Polysurlyn, whose film is made of polyethylene and sarin; and the Aluminum Roll with Polykraft, whose film is made of Kraft paper on polyethylene.

Painted Aluminum Sheet– The painted aluminum sheet has a baked-on finish of highly durable hard film acrylic or polyester paint on the exterior surface. This layer of painting provides improved aesthetics and better corrosion protection for the aluminum jacketing.

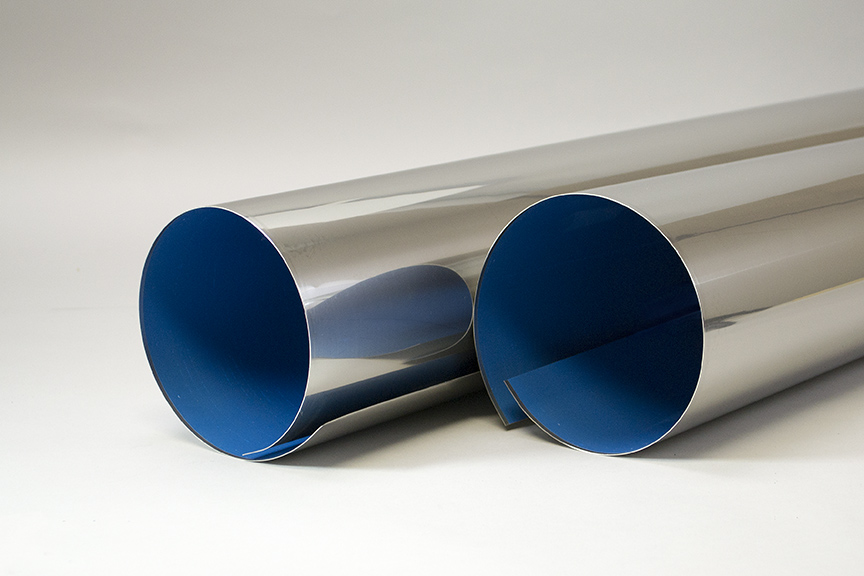

(2). Stainless Steel Roll Jacketing: This stainless-steel roll jacketing is made from T-304 and T-316 prime-grade stainless steels. Compared with aluminum jacketing, this provides superior protection against corrosion and fire. For this reason, stainless-steel roll jacketing is widely used in chemical plants to protect the underlying insulation and pipes from corrosive fumes, leaking chemicals, and other environmental conditions.

3. Where to use the metal jacketing?

Generally speaking, metal jacketing plays a key role in the effectiveness and productivity of industrial insulation. The main functions of metal jacketing are the following:

Weather and damage protection

Moisture barrier and vapor retarder

Fire protection

Appearance covering

In terms of its applications, both aluminum jacketing and stainless-steel jacketing are widely used for equipment insulation, such as pipe and fitting insulation, insulation of tank and vessel heads, chemical plants, refineries, and power plants, etc.

4. What kind of metal jacketing does ECOIN provide?

As we mentioned before, ECOIN provides you a great variety of metal jacketing. As a professional aluminum sheet supplier, we offer aluminum jacketing of insulation with high quality, including all further fabrication processes as you demand, such as embossing, grooving, and painting, etc.

Besides, as a professional stainless steel sheet supplier, ECOIN offers stainless steel jacketing with variable surface textures, including smooth, stucco-embossed and cross-crimped. To increase the corrosion resistance, we also provide stainless steel jacketing with a moisture barrier of polysurlyn or poly kraft.

For further information, welcome to contact us by email sales@insulationecoin.com or by WhatsApp: +8618649161302