Ⅰ. What is foam glass?

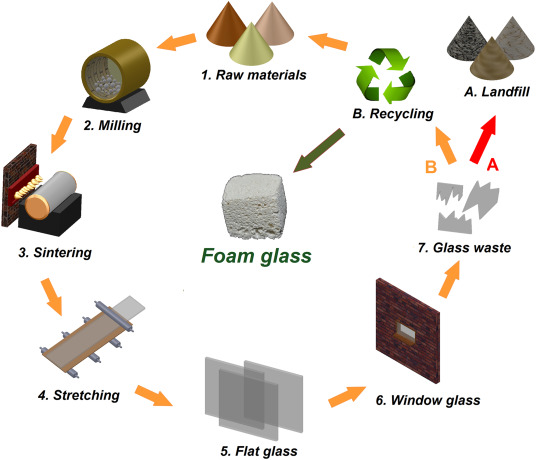

Foam glass insulation material, also known as cellular glass insulation, is a porous glass material. It’s 100% glass-manufactured from sand, limestone, and soda ash. These ingredients are melted into molten glass and crushed into a fine powder. Then this finely ground glass reacts with carbon black: through a melting process, this mixture expands and produces the mass of black foam, which is also known as a “cellulation” process.

This cellulation process creates carbon dioxide filling insulating bubbles. Generally, there are 350 million air cells of CO2 per m³. CO2 is inert air and a good insulator. It accounts for more than 99% of the gas in the insulating bubbles.

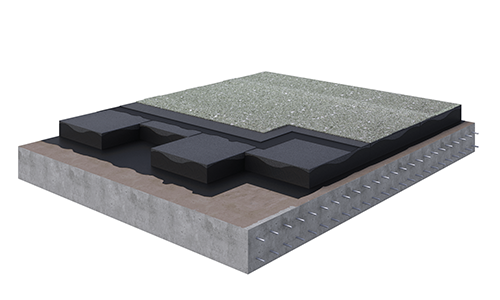

This cellular structure makes foam glass insulation material well insulating: the average R-value of foam glass insulation is 3.44 per inch. Besides this cellular structure also gives foam glass insulation material a high compressive strength, which makes it appropriate for roof decks, green roofs, and parking decks.

Ⅱ. The properties of foam glass insulation

As we mentioned before, cellular glass insulation material is of closed cell structure capturing CO2 in the cells. This structure with gas inside gives the insulating property to the material and ensures stable thermal conductivity for many years.

More specifically, the properties of cellular glass insulation are the following:

1. Chemical inertia

Foam glass insulation material is made from silicate glasses. This inert nature of silica instills the material with its chemical durability. Besides, compared with materials of fibrous structure, this foam glass with closed-cell structure is more stable: unlike the fibrous material, cellular glass insulation material contains no organic binders that can be destroyed by chemicals.

2. Long-lasting thermal performance

The material’s insulation effectiveness depends on its ability to resist heat transfer: the lower the thermal conductivity of the material, the greater its resistance to heat flow (To know more about thermal conductivity, please click: What is the R-Value of Insulation Materials? Compared to liquids and solids, air and other gases are of lower thermal conductivity. Therefore, many insulating materials function simply by having a large number of gas-filled pockets. Characterized by millions of insulating bubbles, foam glass insulation material offers a good thermal performance: under a service temperature ranging between -125 °C and 204°C, cellular glass insulation provides a constant insulating efficiency throughout the full lifetime of the building or industrial installation.

In particular, foam glass is widely used for cryogenic insulation. As a professional foam glass manufacturer, ECOIN offers foam glass products for efficient cryogenic insulation. For more information, please click: Ecoin Foam Glass Insulation

3. Fire resistance

Cellular glass insulation product is made of inorganic material that doesn’t burn nor contribute to fire spread. Besides, it doesn’t release smoke or toxic gases, nor produce flaming droplets which can cause injury and contribute to fire development.

Even though it’s exposed to flame of high temperature, foam glass isn’t able to burn easily: its melting point is in excess of 1000°C, and a large part of its core remains after 90 minutes. Moreover, even the foam glass melts, there’s still a process called vitrification that forms a hard “protective layer” on the surface of the material.

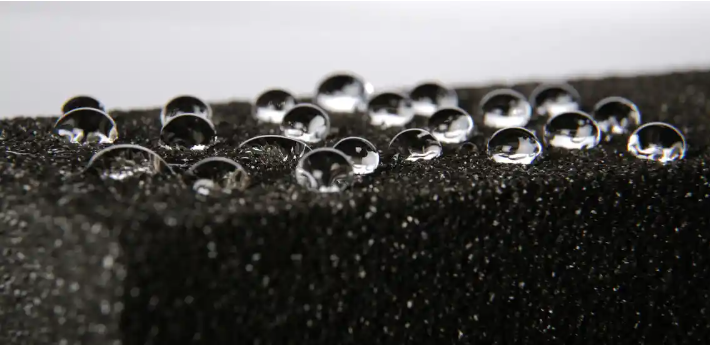

4. Water resistance

Thanks to its cell structure, cellular glass insulation material is completely waterproof and vapor-tight. Our foam glass insulation materials remain watertight for the life of the building, which means that no separate vapor control layer is required.

Besides, a waterproof cellular glass insulation material helps to detect any possible leak: as the foam glass doesn’t absorb water, the water cannot enter the insulation layer and pass through the whole structure; this helps to locate the leak more accurately.

5. High compressive strength

Foam glass is comprised of millions of hermetically sealed, closed glass cells that don’t distort or warp easily. This structure provides cellular glass with high compressive strength: our cellular glass is capable of bearing loads of 0.5MPa to 2.4MPa through the lifetime of the application, maintaining its insulation properties without compression, degradation, or distortion.

Thanks to this property, cellular glass is ideal for high-traffic applications, such as emergency fire vehicles, maintenance trucks, etc. Besides, it’s also the best insulation for industrial piping and storage tanks where constant pressure is inevitable.

6. Environment friendly

Foam glass itself contains no hazardous components: it’s mainly made of silicate glass. Besides, thanks to its high resistance to water and fire, there’s no need for other chemical agents such as flame retardants, which might cause environmental damage.

Moreover, after generations of use as thermal insulation, foam glass materials can be recycled as filler in landscaping or thermally insulating granulate for meaningful ecological recycling through re-uses.

Ⅲ. Applications of cellular foam glass insulation

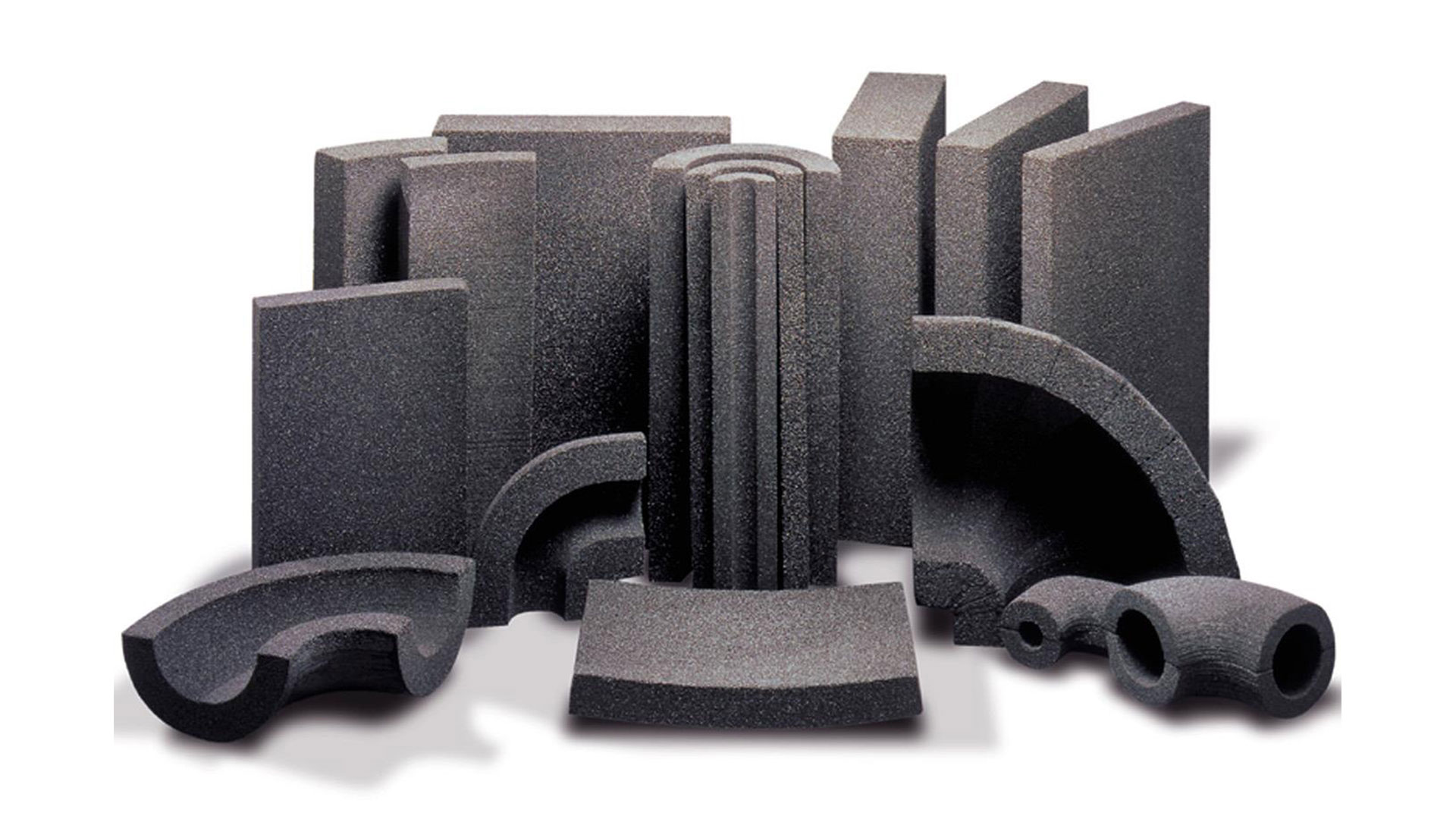

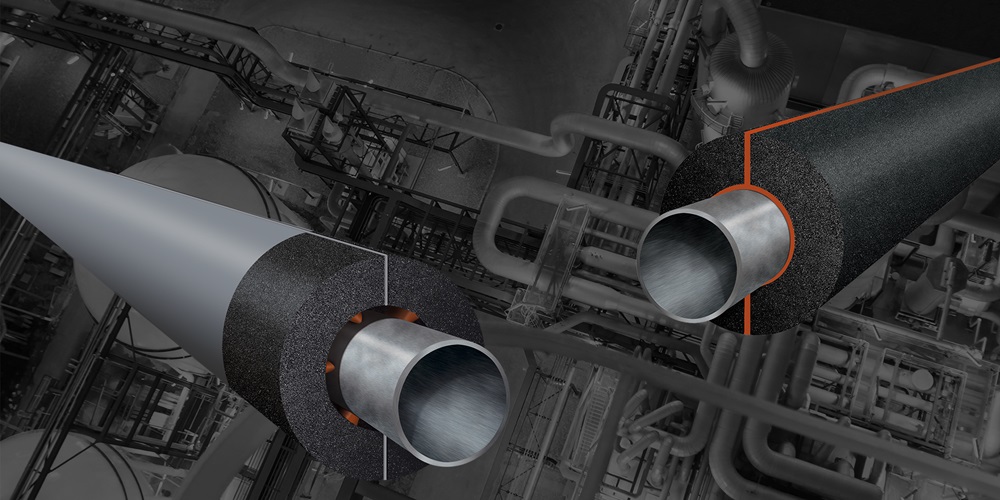

Like other thermal insulation materials, cellular foam glass insulation products have two main applications: commercial and industrial usage. The most popular types are foam glass block insulation products for buildings and foam glass pipe insulation products for piping systems and industrial processing equipment.

Commercial applications of foam glass insulation

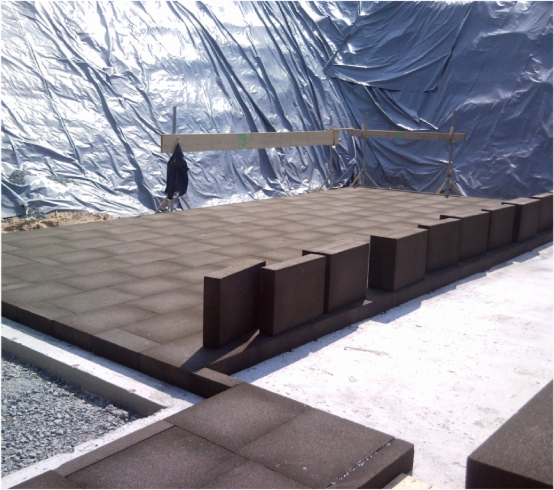

1. Foam glass roof insulation

Cellular foam glass insulation material is durable, lightweight, and water-resistant, which makes it an ideal choice for roof insulation. As we mentioned before, if a leak occurs in the roof, water can enter the roof build-up and pass through the whole building structure. This can cause widespread damage and this location often doesn’t respond to the location of the leak. It’s hard to find where water entered the building initially. Foam glass roof insulation is watertight preventing water or moisture from passing through the roof, which prohibits any possible leakage from the roof.

Actually, cellular foam glass insulation is applied to protect and insulate roofs of mission-critical buildings, such as archives, airports, casinos or paper mills, etc.

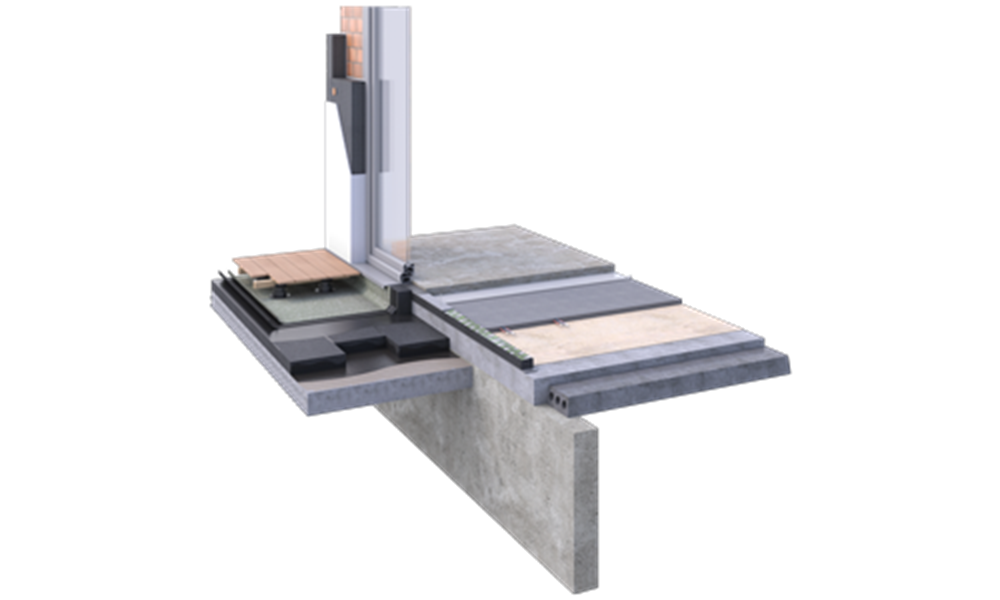

2. Foam glass for thermal bridging solutions

In many civil and commercial buildings, thermal bridges are responsible for heat loss. Thus the continuity of insulation to prevent thermal bridging is very important, particularly in building junctions. Cellular foam glass insulation products act as a thermal break to maintain this continuity of insulation and keep buildings more energy efficient: foam glass board is used for insulation of an exterior wall or a cavity wall construction; foam glass block insulation products are used for thermal insulation under doors and windowsills.

As we mentioned above, this cellular foam glass insulation materials have rigid and closed cellular matrix, which doesn’t only block heat transfer but also bears the load of walls.

Industrial applications of foam glass insulation

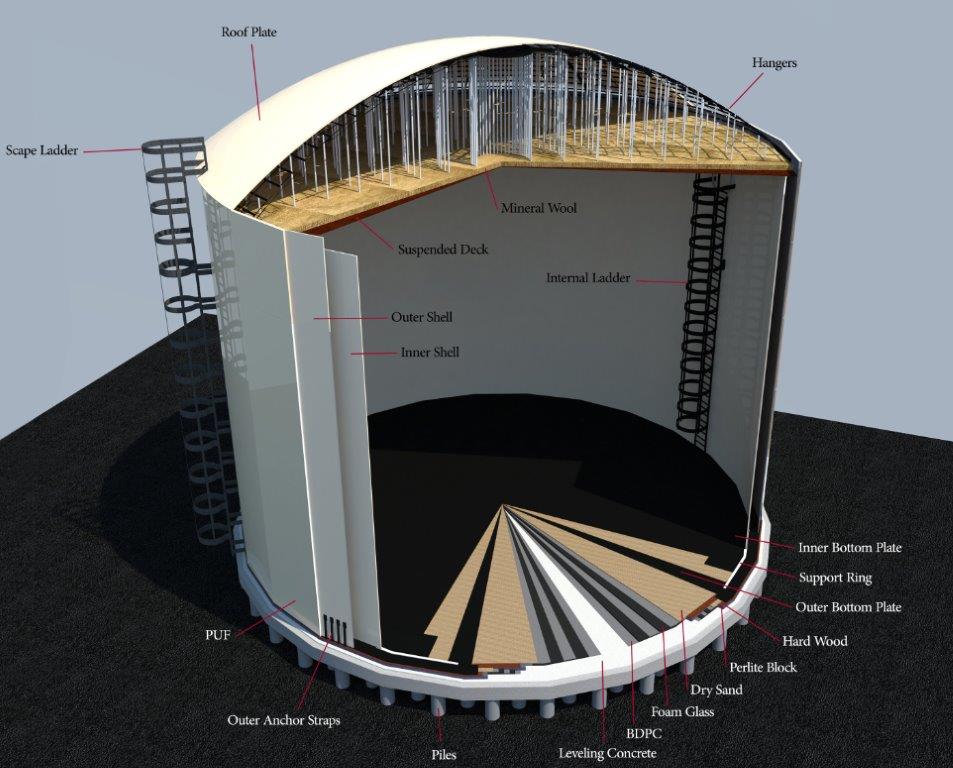

Compared with commercial applications, industrial applications require more strict temperature control, therefore they rely on thermal insulation performing reliably and consistently. In particular, many industrial processes are under below-ambient temperatures (the temperature can drop to -120 °C), which require cryogenic insulation. For example, in a Liquefied Natural Gas (LNG) system, cellular foam glass insulation is the best choice to prevent the liquid from freezing or solidifying.

1. Foam glass insulation for oil &gas storage tanks

Since the 1960s, cellular foam glass insulation products have been used for tank insulation systems: its low thermal conductivity makes it a good choice for strict temperature control; its wide range of working temperatures makes it suitable for insulating liquified gas in storage tanks; its high compressive strength makes foam glass a good material for tank base insulation systems.

Nowadays, cellular foam glass insulation products are widely used for insulating hot, cold, and cryogenic tanks.

2. Foam glass pipe insulation

For chilled water piping systems such as LNG facilities, foam glass pipe insulation is an ideal choice: our cellular glass insulation material offers efficient thermal insulation under temperatures up to -120 °C, which makes it suitable to insulate liquified gas. Besides, our foam glass pipe insulation products combine physical strength, fire resistance, and moisture resistance to provide safety and security.

There’s a high demand for foam glass insulation materials in these piping systems, and various forms of cellular glass insulation products are required: such as foam glass pipe insulation, elbows, T sections, etc. As a professional foam glass manufacturer, ECOIN offers foam glass insulation products in different types. For more information, please click: Ecoin Foam Glass Insulation

Ⅳ. How to install cellular foam glass insulation?

Different applications correspond to different methods of installation. Generally speaking, foam glass is mainly used for the following installations.

Foam glass roof insulation-For foam glass roof insulation, the bitumen coating is required: first, apply a bituminous primer on the concrete surface of the roof; then apply the foam glass roof insulation slabs on the hot bitumen so that they are fully bonded to the substrate; lastly, apply a top coating of bitumen on these foam glass insulation slabs.

Foam glass insulation for walls-To prevent thermal bridging, foam glass block insulation products can be used below masonry veneer walls. These foam glass block insulation materials are also applied in the gap of cavity walls or under doors and windowsills.

Foam glass insulation for tanks- Normally, tank walls and roods are viewed as the largest sources of energy loss; however, unless the tank is filled, the tank’s biggest source of energy loss is the bottom. Thus, the foam glass insulation material is applied to install an insulation system on the base.

This tank base system doesn’t only limit heat transfer, but also provides adequate compressive strength to support the tank.