*high degrees of resistance to process chemicals or environmental agents.

*Due to higher level of molybdenum and nickel, 316 has higher corrosion and pitting resistance than 304 stainless sheets.

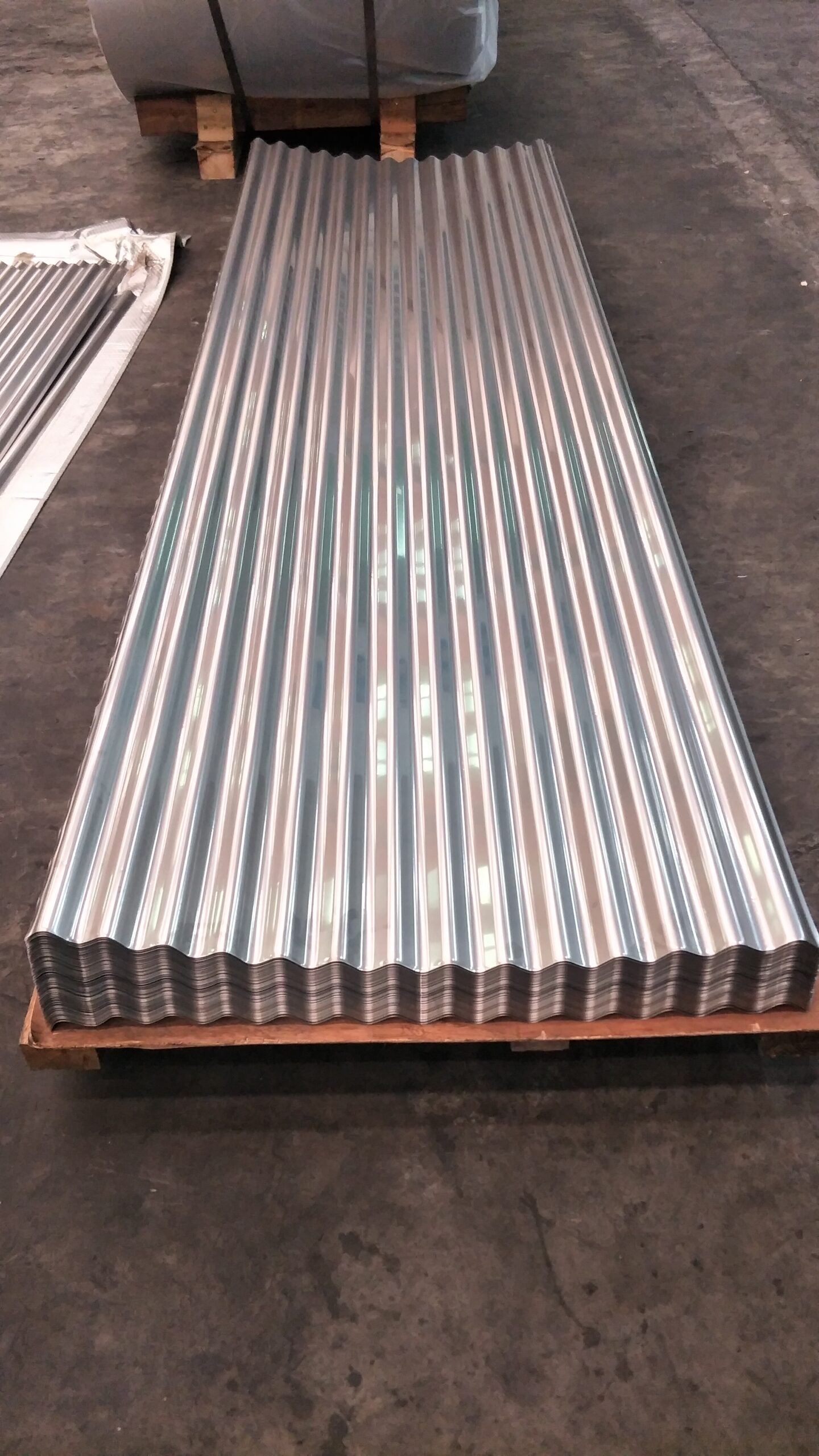

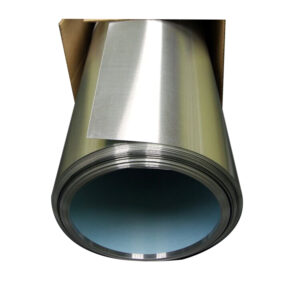

Stainless Steel Jacketing

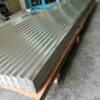

Stainless Steel Roll Jacketing is produced from T-304 Stainless Alloy, soft-annealed temper, conforming to ASTM A-240 specification, and supplied with a standard 2B mill finish. Available surface textures include smooth, stucco-embossed, and cross-crimped. T-316 Stainless Steel Jacketing is also available for increased corrosion resistance where required. Jacketing is available with interior side plain or with either of the following moisture protection membranes:

*Polysurlyn – 3-Mil Coextruded Film

*Polykraft – 40-LB Kraft & Poly Laminate Both Polysurlyn and Polykraft membranes are heat and pressure bonded to the interior surface of the jacketing.

Alloy: 304, 316

Finish: 2B mill finish

Available in smooth or stucco finish

Widths: 36″, 48″ and 1000mm

Thicknesses: .016″, .020″, .024″, .032″, .040″

Length: 100ft, 150ft, and jumbo rolls

Stainless Steel Jacketing Manufacturers, Factory, and Suppliers From China, We are sincerely looking forward to cooperating with buyers all around the world.

*Stainless steel Chemical Composition

| C | Si | Mn | P | S | Cr | Ni | Others | |

| SUS 316 | ≤ 0.08 | ≤ 1.00 | ≤ 2.00 | ≤ 0.045 | ≤ 0.030 | ≤16.0-18.0 | ≤ 10.-14.0 | Mo:2- 3 |

| SUS 304 | ≤ 0.08 | ≤ 1.00 | ≤2.00 | ≤ 0.045 | ≤ 0.030 | ≤18.0-20.0 | ≤8.0-10.5 |

*Stainless Steel Mechanical property

| YS(Mpa) | TS(Mps) | EL(%) | Hv | |

| SUS 316 | ≥205 | ≥520 | ≥40 | ≤ 200 |

| SUS 304 | ≥205 | ≥520 | ≥40 | ≤200 |

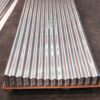

Stainless Steel Jacketing is recommended for use in applications requiring high degrees of resistance to process chemicals or environmental agents. It is also well suited for applications requiring high degrees of resistance to mechanical abuse and exposures to extreme temperatures such as those commonly required in fire protection systems.