With Mineral Wool external wall insulation, living spaces can be made cool, energy-efficient, and compliant with modern building standards – as well as gaining additional benefits in terms of acoustics, indoor comfort and fire safety.

Mineral Wool External Wall Insulation

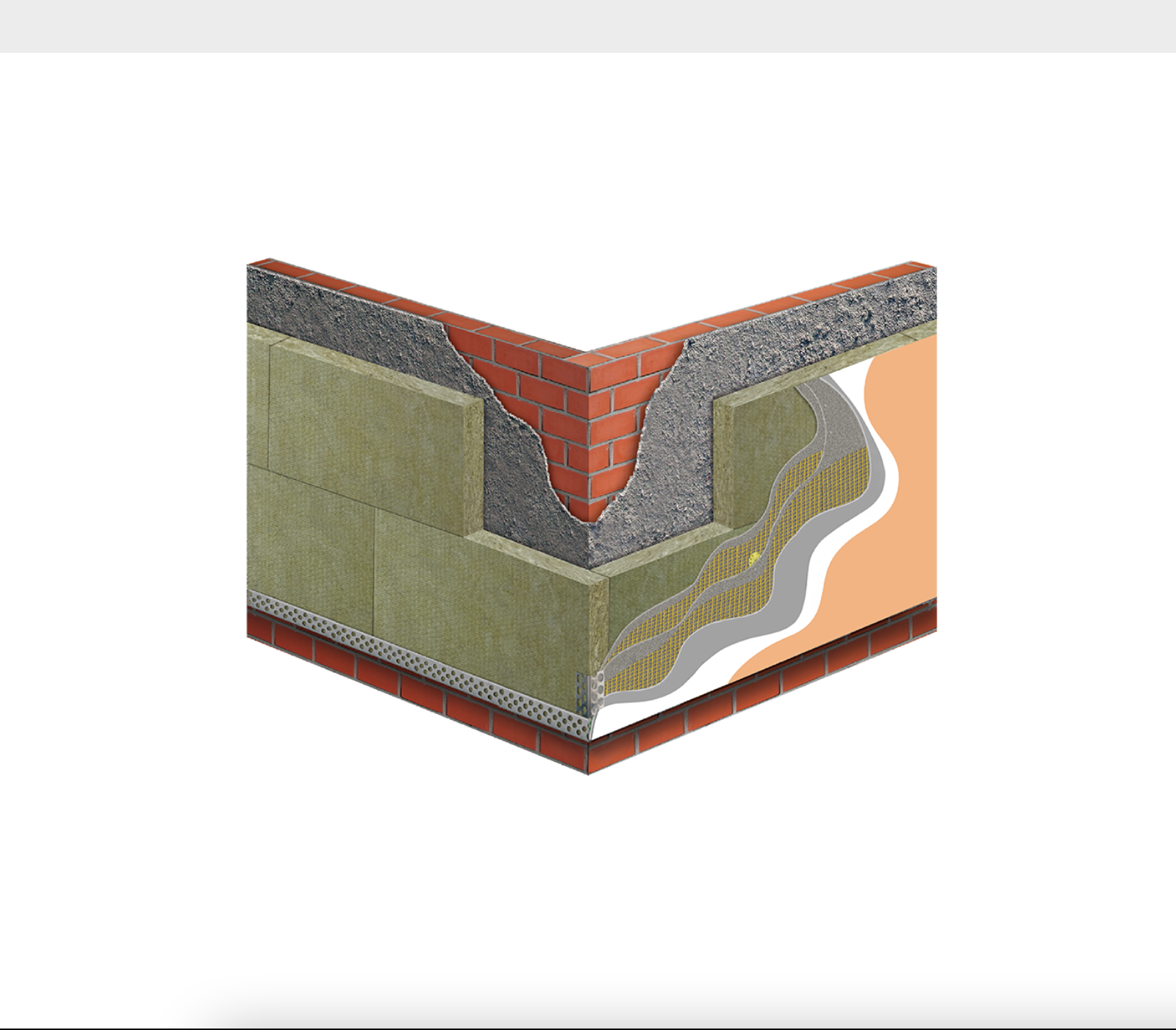

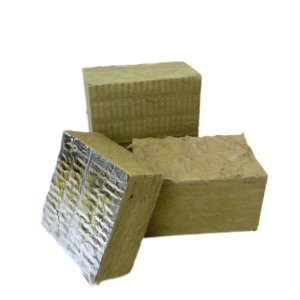

Ecoin Mineral Wool External Wall Insulation is designed for external thermal insulation composite systems and dry-hanging curtain wall systems as a fireproof insulation material. With high compressive and tensile strength, and excellent hydrophobic and moisture-proof properties, it can be applied on all kinds of solid wall substrates such as masonry and concrete, and both suitable for new/expansion project and retrofitting project of existing buildings. When a fire breaks out, the product’s class-A non-combustibility and fire-proof performance can effectively prevent the spread of fire.

Raw materials: Basalt, dolomite

Density(kg/m3): 140-200kg/m3

Size: L(m)xW(m): 0.6×1.2m

Thickness(mm): 40-100

Asbestos: 100% Non Asbestos

Facing: Unfaced, Aluminum Foil-faced

Function: Thermal insulation, Sound absorption

Fire Rating: A1 Non-combustible

Mineral Wool External Wall Insulation Manufacturers, Factory, and Suppliers From China, We are sincerely looking forward to cooperating with buyers all around the world.

| Properties | FRB 75 | FRB 100 | FRB 150 | Unit | Test Method |

| Tensile Strength (perpendicular to surface) | ≥7.5 | ≥10 | ≥15 | kPa | GB/T 30804 |

| Compressive Strength (10% deformation) | ≥40 | ≥50 | ≥60 | kPa | GB/T 13480 |

| Thermal Conductivity(25℃) | ≤0.039 | W/(m•K) | GB/T 10295 | ||

| Reaction to Fire | Class A | — | GB 8624 | ||

| Melting Temperature | ≥1000 | ℃ | — | ||

| Fibre Diameter | ≤6 | mm | GB/T 5480 | ||

| Acidity Coefficient | ≥1.8 | — | GB/T 5480 | ||

| Water Repellence | ≥99 | % | GB/T 10299 | ||

| Mass Moisture Absorption | ≤0.5 | % | GB/T 5480 | ||

| Short-term Water Absorption (partial immersion, 24h) | ≤0.2 | kg/m² | GB/T 30805 | ||

| Long-term Water Absorption (partial immersion, 28d) | ≤1.0 | kg/m² | GB/T 30807 | ||

| Dimensional Stability | ≤0.5 | % | GB/T 30806 | ||

| K2O + Na2O | ≤5.0 | % | GB/T 1549 |

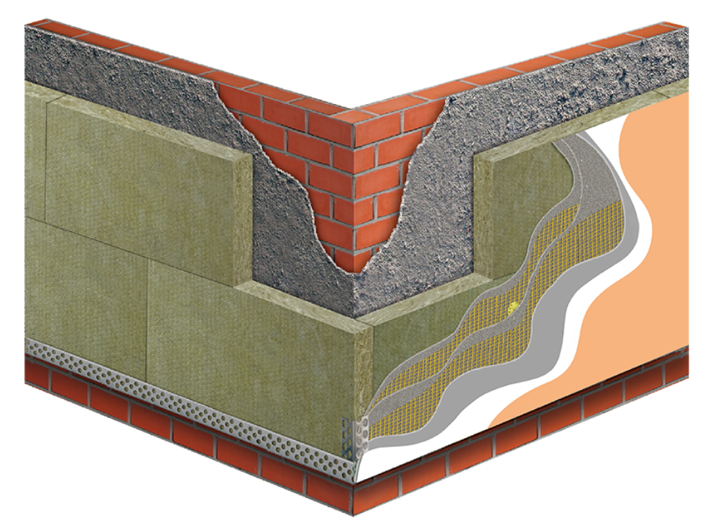

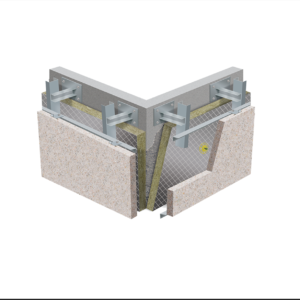

Applicable to thin plaster insulation system for external wall, mainly used with the typical structure as shown in the following diagram

1. Substrate

2. Adhesive Mortar

3. ECOIN External Thermal Insulation Board

4. Base Coat

5. Anchors

6. Finishing Coat

7. Corner Protection Rail

8. Starter Rail

In order to give full play to Mineral Wool’s vapor permeability, impermeable facing materials such as ceramic tile, and high elastic paint should be avoided when Mineral Wool external thermal insulation composite system is applied, so the mildew and condensation of the building can be prevented.