PIR insulation board is popular among all insulation categories. It is one of the most versatile, thermally efficient and readily accessible insulation materials available today. A step up from polyurethane, the PIR board has one of the highest R-values per thickness compared to any other insulation material in the market.

*Highly durable: PIR insulation is highly durable and lasts longer.

*Lightweight: It is easy to handle and transport, making installation much faster. Their small weight makes them ideal for modern construction technologies and lightweight supporting structures.

*Versatile: Used for a variety of industrial insulation purposes.

*Moisture resistant: PIR insulation boards do not absorb moisture and thus, retain their weight and insulation properties.

*Resistant: PIR insulation boards retain their original shape even after much wear and tear.

PIR Foam Insulation Manufacturers, Factory, and Suppliers From China, We are sincerely looking forward to cooperating with buyers all around the world.

| Item | Unit | Technical Data | Testing Method |

| Density | kg/m² | ≥40 | ASTM D1622/ ISO 845 |

| Thermal Conductivity at Ambient Temperature (180 Days Aged) | W/(m-K) | ≥0.035(+100℃) | ASTM C177 |

| ≥0.029(+50℃) |

| ≥0.025(+10℃) |

| ≥0.024(0℃) |

| ≥0.023(-50℃) |

| ≥0.022(-100℃) |

| ≥0.017(-150℃) |

| ≥0.016(-170℃) |

| Compressive Strength (AlI Directions) | +23℃ | kPa | ≥200 | ASTM D 1621 |

| -165℃ | ≥280 |

| Tensile Strength (AII Directions) | +23℃ | kPa | ≥320 | ASTMD 1623 |

| -165℃ | ≥265 |

| Flame Spread Index | | <25 | ASTM E84 |

| Oxygen Index | | ≥30 | GB/T 2406.2 |

| Water Absorption by Vol | % | ≤5 | ASTM D2842 |

| Water Vapor Permeability | ng/(Pa-s-m) | ≤5.5 | ASTM E96 |

| Closed Cell Content | % | ≥95 | ASTM D6226 |

| Linear Thermal Expansion Cefficient | m/(m-K) | ≤70x 10-6 | ASTM D696 |

| PH Value | | 5.5-7 | ASTM C871 |

| Chloride and Fluoride Content | | Meet the Standard Spefication of Thermal Insulation Materials for Use over Austentic Stainless Steel | GB/T11835 |

| Elasticty Modulus | MPa | ≤16 | ASTM D1623 |

| Service Temp C -196~ +120 | ℃ | -196~+120 | |

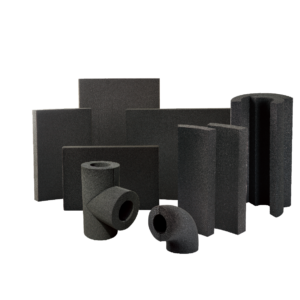

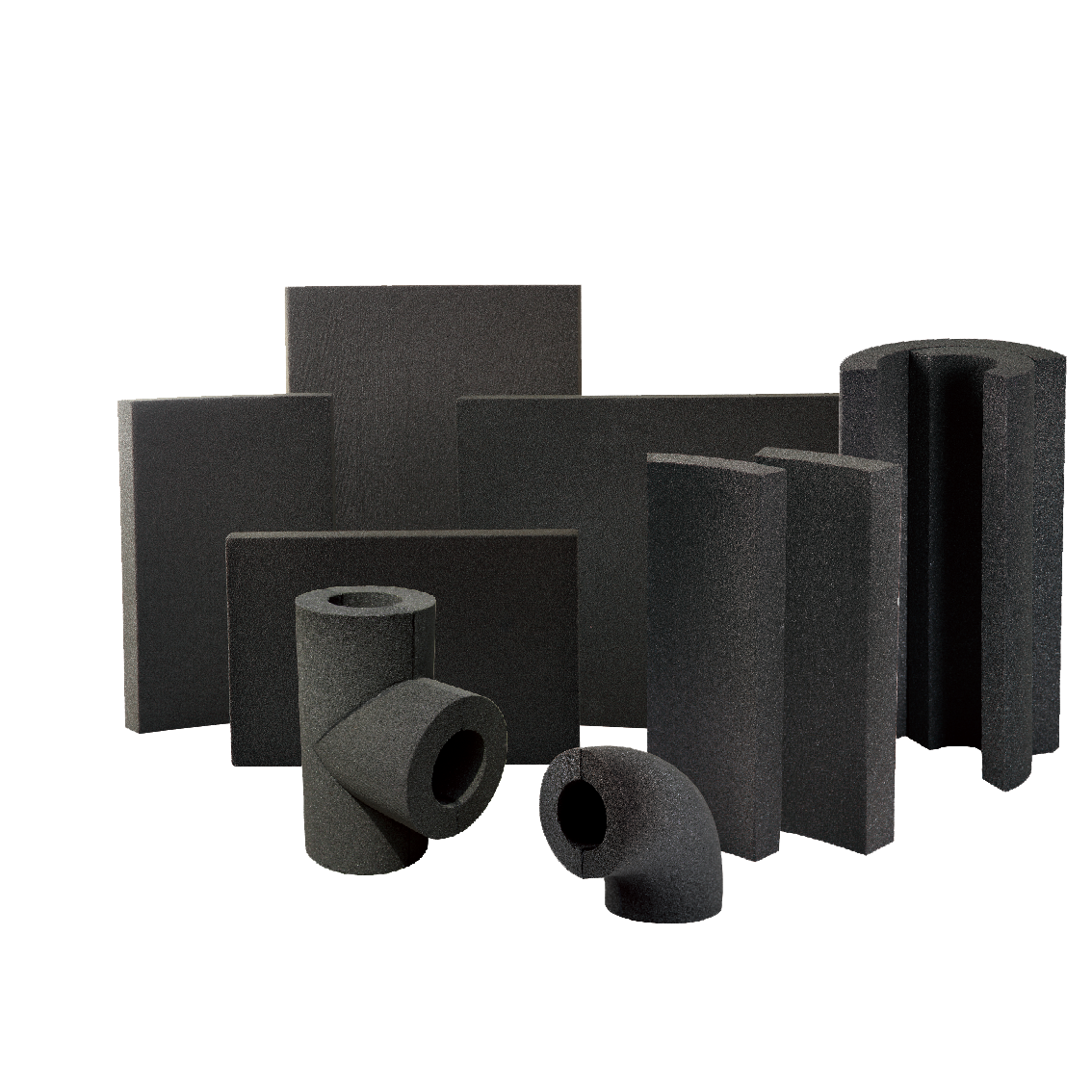

It is a kind of ideal organic thermal insulation material applied at low temperatures, resulting in its low thermal conductivity, lightweight, anti-vibration, and compatibility. It is widely used as insulation in oil refinery, chemical, ethylene, and fertilizer industries, as well as refrigeration house and LNG systems.

*PIR shall be handled gently, avoiding rolling, collision and heavy pressure during moving.

*When applied to pipe and equipment insulation, PIR shall be fastened with glass fiber tape or steel band.

*Cut it with saw during application.

*Store in a dry, lightproof, shady, and ventilated place, keep away from the heat sources and protect from sun exposure.

*Inner Packing: Polythene bags Outer Packing: Cartons.