Ⅰ. What’s the role of insulation pins?

Insulation pins are essential components of any insulation system, used to secure insulation materials like mineral wool, stone wool, glass wool, ceramic wool, aerogel, and PIR and PUR. As well as providing support in both horizontal and vertical positions, insulation pins ensure insulation fits tight to the insulating medium and avoid sagging. To ensure optimal performance, insulation pins must be designed for specific use and installed correctly.

Three of the most common types of insulation pins are weld pins for insulation, stick pins for insulation, and perforated pins for insulation: Stick pins for insulation are the easiest option; Perforated pins and Weld pins offer a more secure fastening.

For which materials insulation pins are recommended?

The insulation materials suitable for fastening with insulation pins are the following: glass wool insulation material, mineral wool, ceramic wool, and foam rubber board, etc. They are both flexible, resilient and lightweight materials, coming in form of batts, rolls, and blankets.

For which materials are insulation pins not recommended?

Insulation pins are not recommended to fix the brittle insulation materials such as foam glass, etc. These materials should instead be glued or fixed with metal bands for better insulation.

Ⅱ. I How to use stick pins for insulation?

1. What are stick pins for insulation?

Insulation stick pins, also known as stick pins for insulation, are widely used for fastening insulation materials to sheet metal. Each pin is equipped with a steel base backed with a Peel & Stick foam adhesive for easy installation. Additionally, a sharp pin is connected to the base that penetrates the insulation, and then a self-locking washer will be installed onto the pin holding the insulation material in place firmly. Once the installation is completed, the extra pin length can be cut for a neat and tidy finish. All in all, stick pins for insulation are an efficient and convenient way of attaching insulation materials to sheet metal.

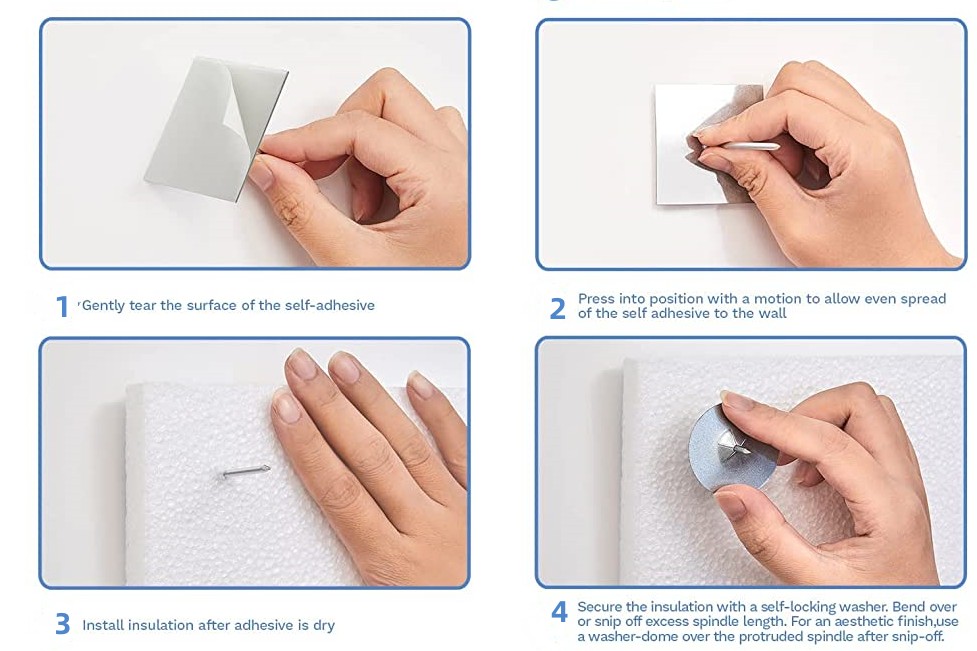

2. How to use stick pins for insulation?

①Peel off the wax release paper.

②Stick the pins onto the surface where the insulation will be placed.

③Put the insulation material in place, and push the insulation onto the pin.

④Push the fixing disc (locking washer) over the pin.

⑤Bend the pin over on itself to avoid it impaling someone.

Note:

①Make sure to stick the stick insulation pins in right place: as these stick pins for insulation are super sticky and it’s difficult to get them off.

②Don’t’ apply the stick insulation pins on surfaces where temperatures are extremely high, such as metal buildings or ceilings where the temperature may exceed 140ºF due to sunlight exposure. The most common application of these stick pins for insulation is fastening the fiberglass wool board on the sheet metal of HVAC ductwork.

③The adhesive layer of this stick pin for insulation helps to separate the metal base of the fastener from the metal surface, which avoids bimetallic corrosion.

Ⅲ. How to use weld pins for insulation?

1. What are weld pins for insulation?

Weld pins for insulation are a popular choice for insulation fastening. These insulation pins are applied using welding equipment and are often used in conjunction with washers. Once the pin is welded, the insulation is impaled over the pin and secured with an insulation washer, also known as a speed clip. These weld pins for insulation come in various types, sizes and materials: the most popular types are cup head weld pins and double-pointed weld pins; they are available in aluminum, low carbon steel, mild steel and stainless steel, depending on the applications.

2. How to use weld pins for insulation?

①Stud the weld pins for insulation in place.

②Hang the insulation material on the weld pins.

③Press locking washers on the weld pins to secure the material.

④Either clip off the weld pins at washer or bend the weld pins over washer.

Ⅳ. How to use perforated insulation pins?

1. What are perforated insulation pins?

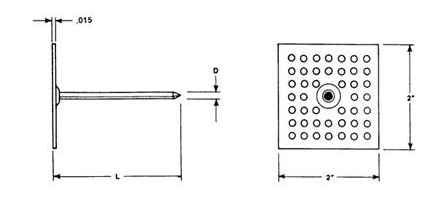

Compared with other types of insulation pins, the perforated insulation pin is a more versatile and effective fastener for attaching various insulation materials. Theses perforated insulation pins are usually equipped with a 12 gauge spindle and a 2″ x 2″ square perforated base made of low carbon steel, galvanized coated. Perforated insulation pins are commonly used with self-locking washers and dome caps in order to support rigid board and batt-type insulation on the wall or ceiling applications.

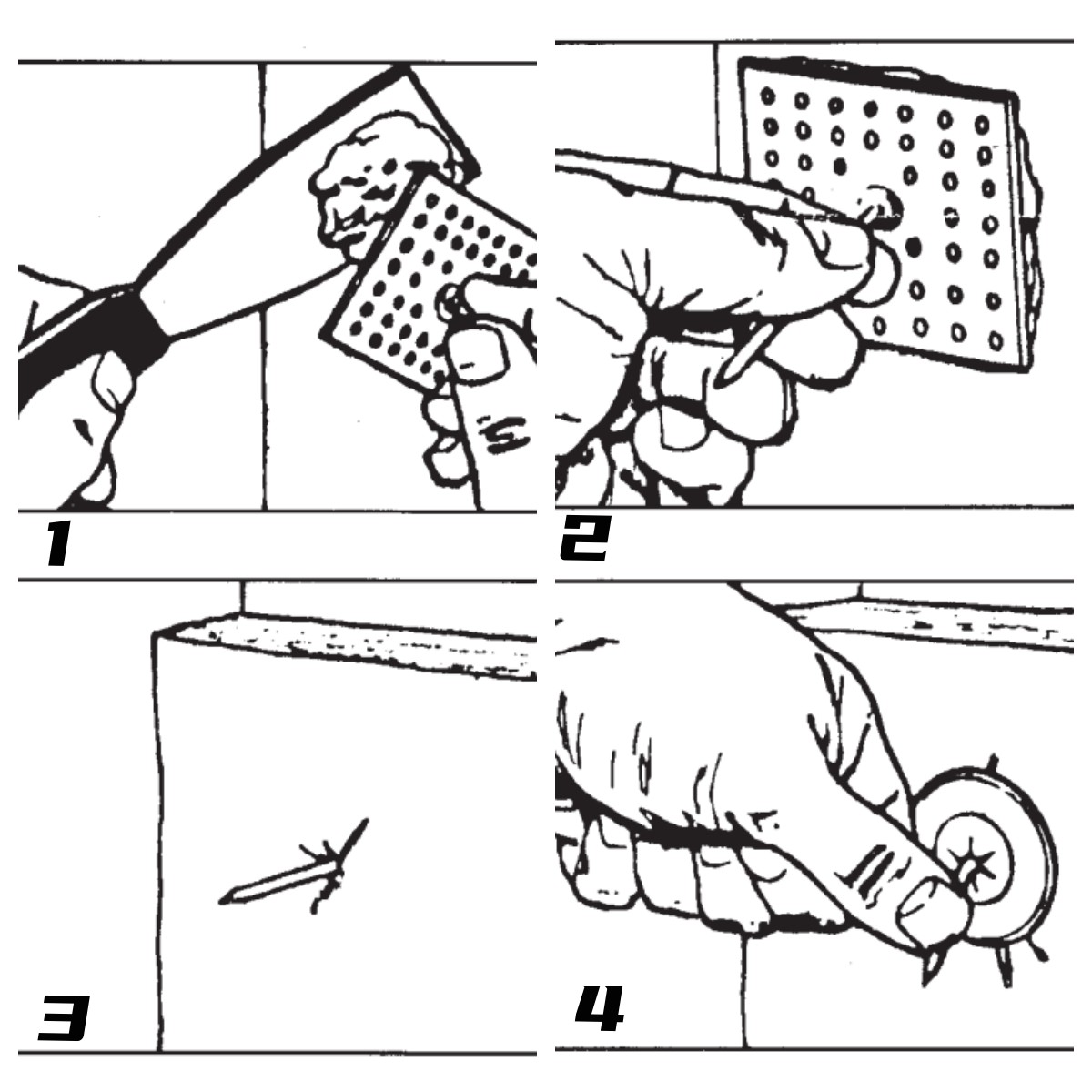

2. How to use perforated insulation pins?

①Wipe the surface clean: make sure that applying surface is dry, clean and non-painted.

②Apply adhesive to the perforated metal base.

③Press the perforated insulation pin into position: make an even spread of adhesive and make sure that the adhesive protrude through the perforations and beyond the edges of the base.

④Hang the insulation materials onto the weld pins.

⑤Secure the pin with a locking washer and then bend over or clip off the spindle.

Note:

*This perforated insulation pin can be fastened with glue, screws or including nails.

*The perforated insulation pin is an excellent choice for fixing insulation to decks and bulkheads, etc.

Ⅴ. How to select the right insulation pin?

As a professional insulation pins manufacturer, ECOIN offers various types of insulation pins, mainly are stick pins for insulation, cup head weld pins of insulation and perforated insulation pins, etc. They are mainly made of galvanized steel or stainless steel. For more information, please click Ecoin Galvanized Insulation Pins

Among so many types of insulation pins, how to select the right insulation pin? The basic principles are the following:

1. When selecting an insulation pin for an industrial project, it is essential to check the technical specifications of the project, in particular when the project involves insulation of ventilation ducts, boiler walls, large vessels, or other equipment, etc. In these cases, the project specifications must be followed strictly.

2. The size of the insulation pin is determined by the thickness of the insulation material, the applied load and the operating temperature. Generally speaking, for industrial insulation with a material thickness of ≤120mm, the minimum diameter should be 4mm; for industrial insulation with material thickness of ≥130mm, the diameter should be of 5mm; for insulation with a thickness of ≥240mm, the diameter should be of 6mm.

3. The length of the insulation pin also has to do with the thickness of the insulation material: usually, the insulation pin should be 10-20mm longer than the thickness of the insulation material.