For insulation work, particularly industrial insulation projects, preventing corrosion under insulation (CUI) is essential to avoid costly repairs, replacements, and potential accidents. To prevent CUI, many factors are involved: proper insulation and maintenance of insulation materials, a series of regular inspections of insulation, and an application of moisture barrier on insulation materials, etc.

First of all, it’s essential to know what is corrosion under insulation.

Ⅰ. What is corrosion under the insulation?

Corrosion under insulation (CUI), also known as CUI corrosion, is a type of oxidation that takes place on the surface of an insulated metal pipe or vessel. When moisture becomes trapped beneath the insulation, the metal is exposed to oxygen in the water, leading to a higher rate of corrosion. CUI can damage the insulation material, hardware, and underlying piping or equipment, regardless of the insulation’s purpose (thermal or acoustic). As such, it is essential to ensure that insulation systems are kept dry to prevent CUI from occurring.

*What triggers CUIs?

Generally speaking, there are factors mainly involved in the corrosion under insulation: the environment, the insulated system itself, the materials of insulation, and the types of metal jacketing. More specifically, these are the following:

Environmental conditions: Hot or humid environments, intermittent wet and dry environmental conditions, high rainfall climates, or an atmosphere containing contaminants, such as chlorides or sulfides, etc.

Operating system: CUI (corrosion under insulation) is a frequent issue within industries that involve gas, oil, and other liquids. Such as petrochemical industries and refineries, etc. Any kind of equipment failure, leak, downtime, and even explosion can cause CUIs.

Insulation materials: There’s a great variety of insulation materials: some are of high moisture resistant, such as mineral wool insulation; some are not and these insulation materials can hold moisture inside the system.

Metal jacketing: Metal jacketing with a protective coating or moisture barriers is critical to prevent condensation.

Ⅱ. How to detect corrosion under the insulation?

Corrosion Under Insulation (CUI) is a difficult problem to spot due to the fact that the insulation layers keep the problem hidden until it is too late. Removing, inspecting and then reinstalling the insulation after inspection is an expensive process. Employing non-destructive testing methods to detect CUI without removing insulation material and aluminum jacketing is a cost-saving solution for the industry. The main detection methods are the following:

Visual inspection: Remove the covering of the system and examine visually the surface for any signs of corrosion or damage.

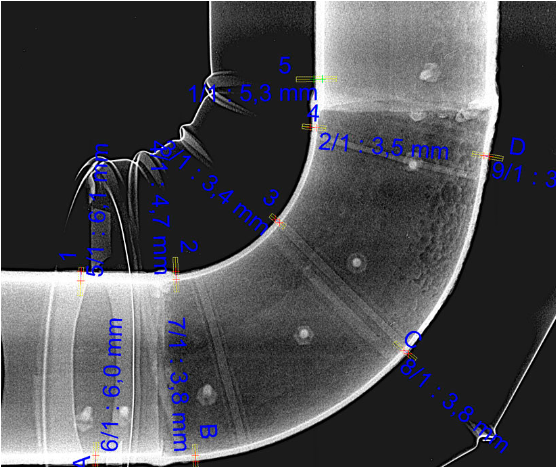

Radiography inspection: It’s a common method to detect corrosion under insulation. There are real-time radiography (RTR), computed radiography (CR), and digital detector arrays (DDA).

Ultrasonic thickness measurement: It’s a highly accurate inspection technique. It measures the system’s wall thickness by detecting the movement of ultrasound waves.

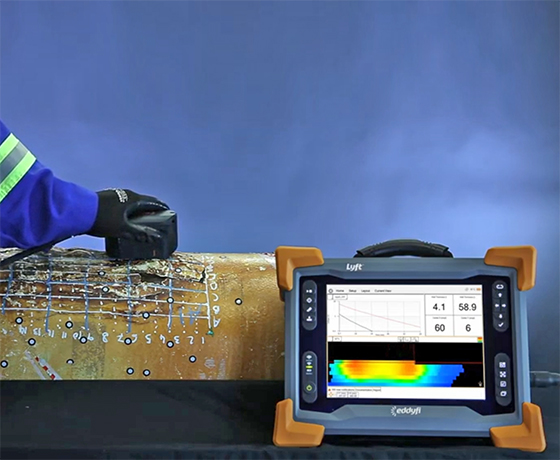

Pulsed eddy current: Similar to ultrasonic measurement, it uses electromagnetic waves to determine the wall thickness of the system. It delivers a higher degree of accuracy.

Ⅲ. How to prevent corrosion under insulation?

Corrosion under insulation (CUI) is a common form of corrosion caused by the intrusion of liquid into the insulation system of a pipe or equipment. This can be caused by weathering, vibration, or abuse from people, which decreases the effectiveness of the insulation and leads to corrosion. To prevent CUI, it is essential to keep liquid away from the insulation system, as this can prevent the corrosion of pipes or equipment.

There are five factors in preventing CUI, as the following.

1. Insulation material selection

Use the wrong insulation material can accelerate corrosion of the underlying surfaces Additional protective method is required where spills, leaks, or drippings may occur, or where washing and hosing are carried out. Insulation products made of inorganic materials are of high moisture resistance, such as rock wool insulation material, etc. Generally speaking, the insulation materials with the closed-cell structure are fully nonabsorbent, such as closed-cell foam rubber and foam glass, etc.

2. Insulation system design

Insulation design plays an important role in preventing corrosion under insulation (CUI). Proper insulation for pressure vessels, tanks, and piping should include consideration of the support and connections of the material. Weather barriers for insulation are often broken due to inadequate initial design specifications or insufficient space around the insulation. To improve the design, the insulation specifications need to be taken into account early during the vessel design. Moreover, the surface to be insulated should be simplified. To sum up, a strategic design of equipment can significantly reduce the risk of corrosion under insulation, as it minimizes and controls the collection of water and vapor between a metal surface and thermal insulation.

In terms of system modifications, potential corrosion under insulation should also be considered. If there’s a possibility of CUIs, a series of regular inspections and removable insulation design should be provided.

3. Protective paints and coatings

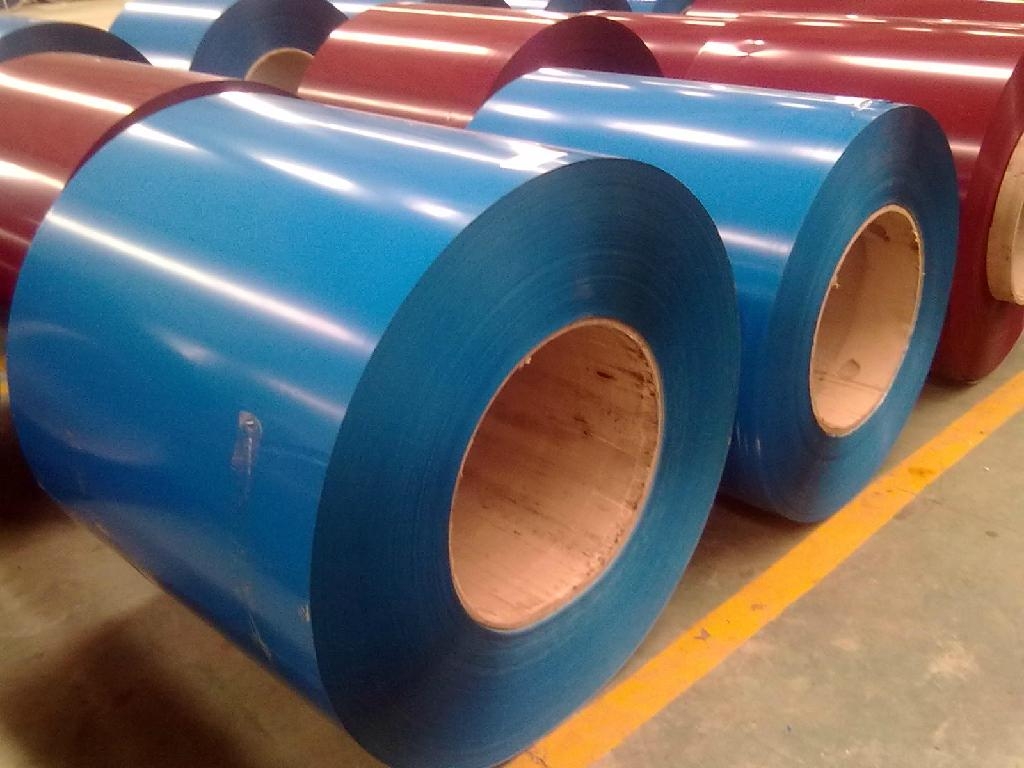

Protective paints and coatings can be used to effectively prevent corrosion under insulation. Aluminum jacketing is normally used to cover the insulation and provide a physical barrier. For this reason, the coatings on this metal jacketing must be highly permeable to protect for long periods against water or corrosives. Service temperature and abrasion resistance are important factors in selecting types of coatings, as well as a service rating for water (or corrosive-chemical) immersion.

It’s worth mentioning that visual inspection of these protective coatings under insulation is not easy, therefore the coatings should be applied and inspected periodically, usually every 10-15 years, to ensure the insulation is adequately protected from corrosion.

ECOIN’s painted aluminum jacketing is a corrosion-under insulation solution that offers superior protection in the toughest of environments. The aluminum is first pre-treated to remove any dirt and debris, then coated with a primer and sealed with a thermoset acrylic paint. This paint system is available in all colors (RAL color charts). The paint offers excellent stain abrasion and mar resistance, giving your project the best possible protection.

For more information, please click: Painted Aluminum Sheet

4. Moisture barriers

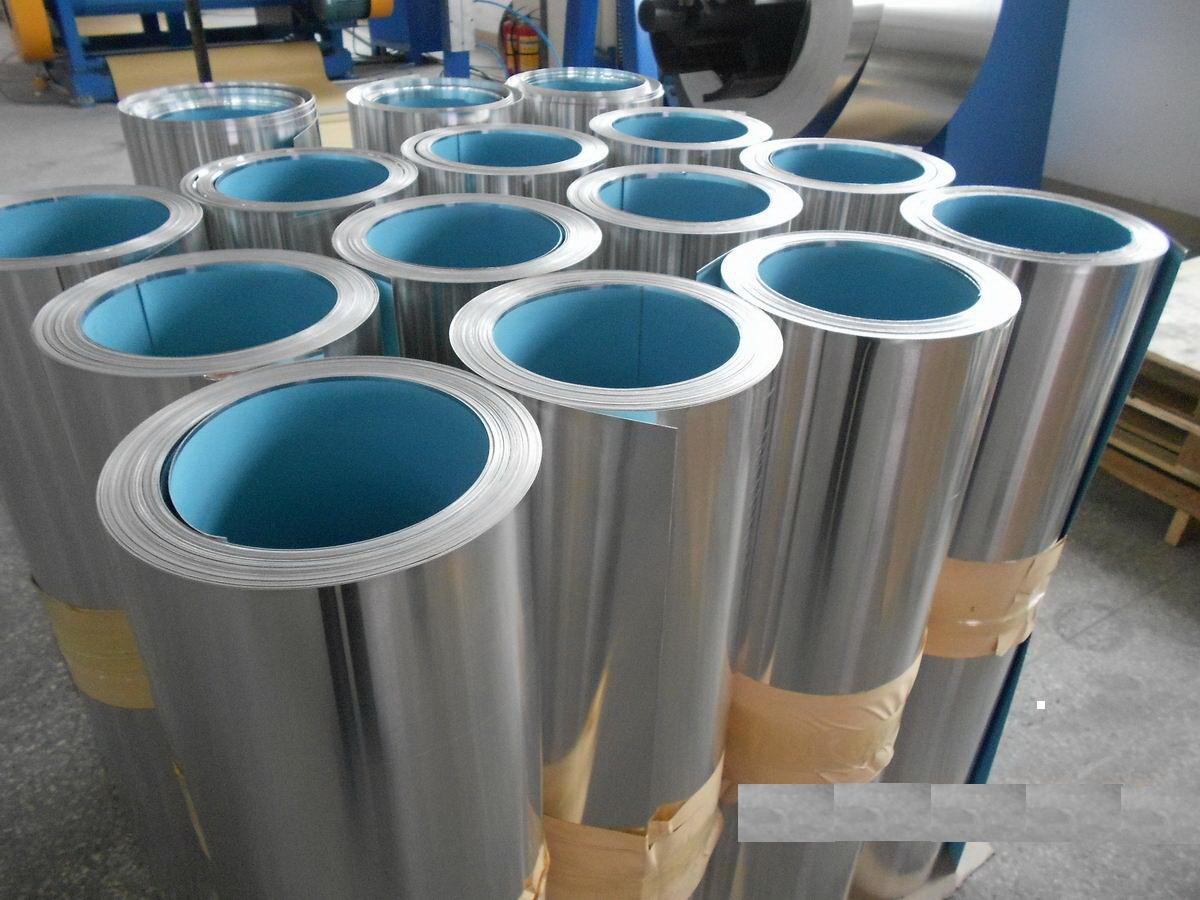

Aluminum Jacketing with Polysurlyn (PSMB)

Aluminum jacketing with Polysurlyn Moisture Barrier (PSMB) is an ideal choice for protecting mechanical insulation from corrosion under insulation and pitting. This advanced three-layer coextruded film has a total thickness of 3 mils (76 µm) and is heat laminated in the factory to the interior surface of the aluminum jacketing. The inner layer is mainly comprised of low-density polyethylene (LDPE) for strong adhesion after heat lamination. The middle layer is made of Surlyn* for strength, while the top layer is predominantly high-density polyethylene (HDPE) for superior toughness and abrasion resistance. By using three separate film layers, this product ensures there are no pinholes through the entire film, making it an effective corrosion-preventing solution.

Normally, this Polysurlyn Film is colored a light blue to distinguish it from other film types and to allow visual confirmation of its presence on the metal jacketing.

To know more about this aluminum jacketing with polysurlyn, please click: Ecoin Aluminum Roll With Polysurlyn

Aluminum Jacketing with Polykraft (PKMB)

Aluminum jacketing with polykraft moisture barrier (PKMB) is a great solution for protecting against corrosion under insulation. This aluminum cladding jacketing has a yellow surface and resembles kraft paper, but is in fact a durable aluminum product. PKMB offers superior protection against moisture, making it an ideal choice for insulation projects.

This Polykraft film is comprised of a layer of kraft paper laminated to a thin layer of polyethylene film, applied to the metal surface in a lamination process. The Polykraft coating is 1.5 mil (37.5 μm) thick and provides excellent moisture resistance, as well as being non-toxic, low cost, and low consumption. Although this coating does provide some protection against mechanical abuse, it does have its drawbacks, such as being easily damaged and promoting the growth of a fire. Therefore, it is not suitable to be used in areas where there is a high risk of fire.

To know more about aluminum jacketing with polykraft moisture barrier, please click: Ecoin Aluminum with Polycraft Moisture Barrier

5. Maintenance practices

In most industrial projects, maintenance work should also be carried out regularly to prevent potential corrosion under insulation.

To prevent corrosion under insulation (CUI), here are the best maintenance practices to consider:

- Ensure that insulation and accessory products are installed according to the recommended procedures.

- Before insulating, turn off cooling and refrigeration systems and let them return to room temperature.

- Make sure to use the correct thickness of insulation for design parameters and contact the Technical Manager for assistance.

- Seal all openings, protrusions, and gaps in the piping systems or tanks to be insulated.

- Utilize pipe hangers and supports to reduce compression points and to accommodate pipe movement.

- Apply a rust inhibitor coating on the piping prior to insulating.

- In areas with high humidity, install zero permeable jacketing to avoid condensation.

- Conduct an annual inspection of the system, piping, and insulation to check for seals and joints. Be aware of any sign of CUI.

- If moisture is found, repair all areas between the insulation and piping.

- Reinstall insulation materials with proper care, making sure that the insulation is installed at the right thickness and sealed correctly.