Ⅰ. How to measure the performance of thermal insulation?

Thermal insulation materials are an important part of any building, as they reduce heat exchange between a surface and the environment or between two surfaces. Generally, the lower a material’s thermal conductivity, the better its insulation properties for a given material thickness. To measure the thermal efficiency of insulation materials, three main parameters are commonly used: K-value, U-value, and R-value. These parameters are related to the two main decisions customers need to make when selecting thermal insulation: the thickness and type of material.

Besides, other factors must also be considered to ensure maximum thermal efficiency. These include:

*Easy installation – for the best performance, materials should be installed without gaps between adjoining slabs, joists, and rafters to avoid air leakage.

*Shrinkage, compaction, and settlement– the designer should take into account any potential dimensional instability and seek guidance from the insulation manufacturer where necessary.

*Resistance to moisture – vulnerable insulation should be protected from moisture, and a suitably resistant material should be specified where there is a high risk of moisture ingress or a relative humidity of over 95%.

Ⅱ. How to measure thermal conductivity?

What’s the value of thermal conductivity?

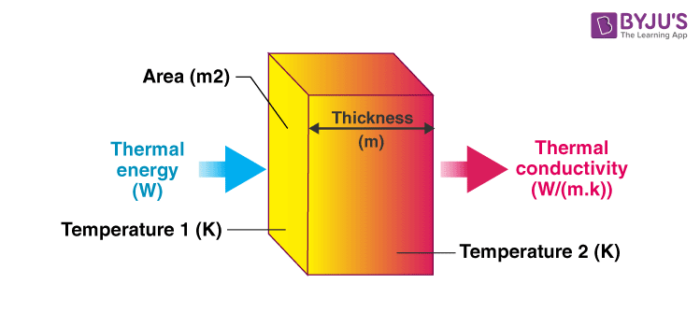

The thermal insulation of a material is indicated by its K-value, also known as a lambda value λ(w/mK). This measure of thermal conductivity is expressed as watts per unit thickness per degree temperature difference across that unit thickness. Low K-values indicate superior thermal efficiency, with most insulation materials having K-values of less than one. The amount of heat transmitted between the two faces of a flat surface of a material is directly related to its coefficient of thermal conductivity (λ). Thus, the lower the K-value, the better the material performs as a thermal insulator.

When choosing a thermal insulator, it is essential to understand how K-value works. K-value is a material property and is independent of thickness. However, the actual K-value for a specific insulation application varies depending on the mean temperature, which is the average of the temperatures on each side of the insulation. As the mean temperature increases, the K-value also increases. Therefore, it is important to consider the K-value at the right mean temperature before selecting a thermal insulation material.

How to measure thermal conductivity?

In theory, there are three different ways to measure the thermal conductivity of insulation materials, which are the following:

Measuring Steady-State Samples-Here the steady-state samples refer to the types of insulation materials such as glass wool and mineral wool. To measure the thermal efficiency of these materials, the hot plate method can be applied.

1. Place the sample between two metal plates, making sure there is enough space for both plates to be heated and cooled.

2. Heat the top plate and cool the bottom plate until the temperatures remain steady.

3. Finally, monitor the amount of heat passing through the sample. This thermal conductivity is measured using a thermometer to measure the amount of heat passing through the sample from the warm side to the cold side.

Measuring Nonsteady-State Samples-Here the nonsteady-state samples refers to the insulation materials in forms of gel or foam.

1. Insert a hot wire into the middle of your sample. Heat the wire and note the temperature it starts at. Nonsteady-state samples are much more likely to be foams or gels that can have a wire inserted into them.

2. Monitor the temperature change in the wire over time. Set a time limit of about 10 minutes to test your sample. Observe the temperature change in the wire while it is inside your sample.

3. Plot the temperature change on a graph. Plot the change in time on one axis and the temperature change on another axis. Utilize the changes in temperature of the wire to calculate the thermal insulation of your sample.

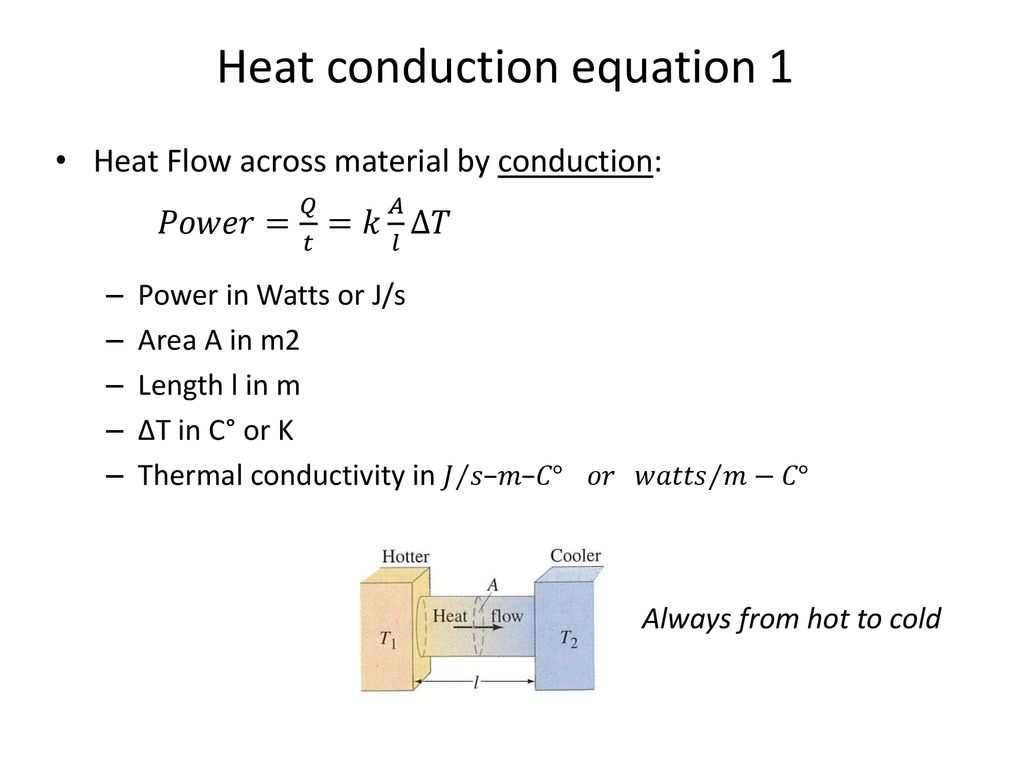

Using an equation to calculate the K-value– The equation Q / t = kAT / d is used to calculate the K-value. This equation takes into account the different variables that can affect heat transfer or loss, such as the amount of heat transferred over time (Q), the change in time (t), the thermal conductivity constant (k), the cross-section of the sample conducting heat (A), the difference in temperature from the cold side to the hot side of the sample (T), and the thickness of sample (d).

III. How to measure thermal resistance?

What’s the thermal resistance?

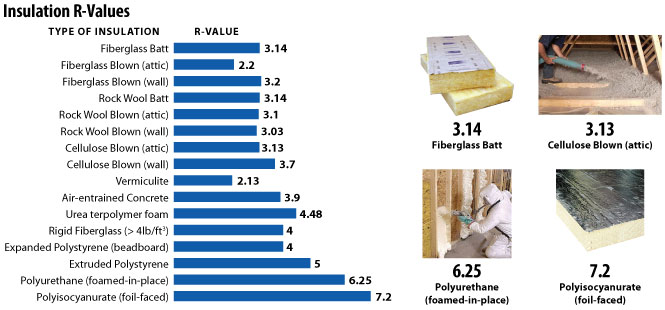

Thermal insulation is a critical factor when considering the thermal resistance of a material. The R-value, expressed in m²K/W, is used to measure the thermal resistance of a material or its ability to resist heat flow. It indicates how much heat is transferred through the thermal insulation material and the temperature variation over the material. The higher the R-value, the more effective the thermal insulation material will be at preventing the transfer of heat. To calculate the R-value, the thickness of the material is taken into account, unlike the lambda value. Therefore, the R-value is a reliable measure to determine the performance of thermal insulation.

How to measure the thermal resistance?

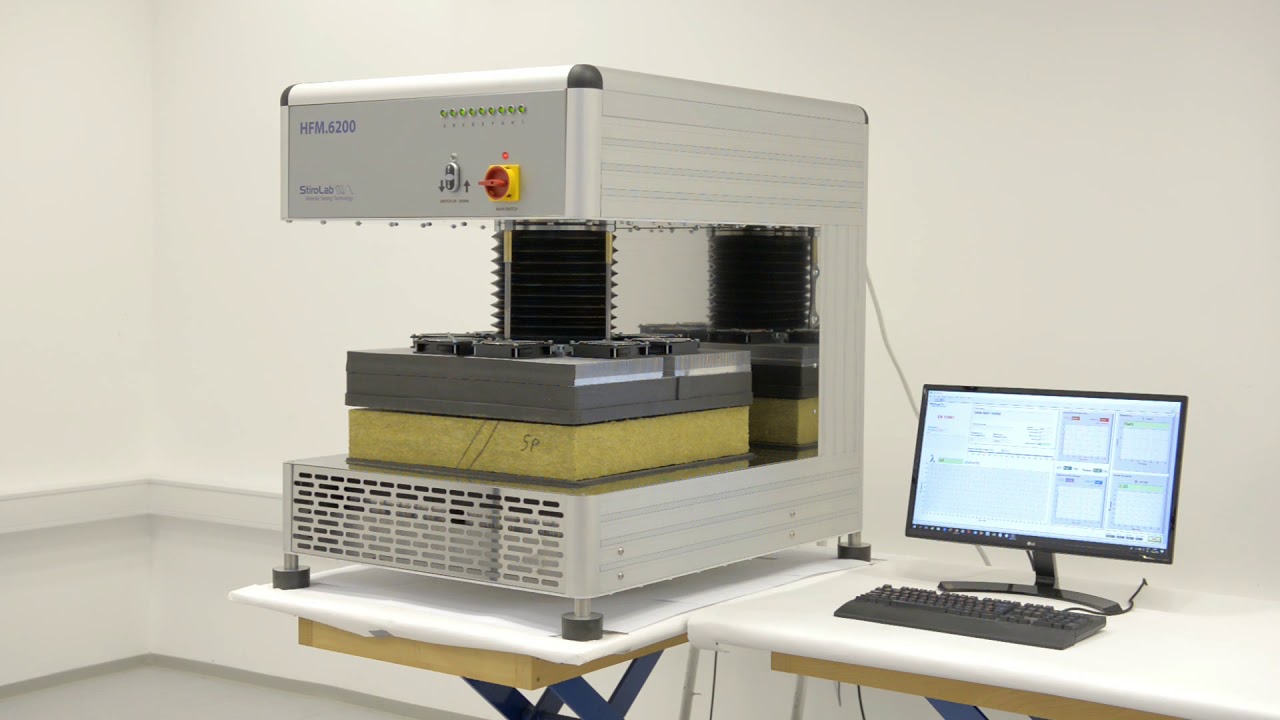

Heat Flux Sensor, also known as the Heat Flow Meter (HFM) is the golden standard for measuring the thermal resistance of thermal insulation. This method is the only one that does not require damage to the material nor does it provide merely qualitative R-value numbers. HFM allows us to measure the thermal conductivity from -10 to 60 °C, which is far more efficient than other methods such as relying on the original manufacturer’s specifications for a material. In addition, HFM takes into consideration factors that may affect thermal performance such as degradation over time, humidity, or physical damage, making it the most comprehensive method of measuring thermal insulators.

Ⅳ. I How to calculate heat loss?

U-value vs R-value

U-Value is a measurement of thermal transmittance, or more specifically, this reflects the thermal loss of the materials. In essence, the lower the U-Value, the better the thermal insulator is. Like the K-value, the U-value is also a parameter to measure the transmission of heat flow through the material; however, the U -value is often used to measure the insulating characteristics of the glass, or how much heat flow or heat loss occurs through the windows or doors due to the difference between indoor and outdoor temperatures.

As we mentioned before, the U-value mainly measures the thermal transmittance; on the other hand, the R-value measures the thermal resistance this heat flow through the These two values are mathematical reciprocals of each other, and to calculate one from the other, one can simply divide 1 by the other. For example, a U-value of 0.10 would equate to an R-value of 10, while a 3.45 R-value would equate to a U-value of 0.29. The lower the U-value and the higher the R-value, the better the thermal efficiency of the material.

How to calculate heat loss?

Calculating the heat loss in a building requires taking into account the U-value, which measures the thermal transmittance of materials as the rate of transfer of heat through matter. Actually, this rate of unwanted heat loss can be expressed with different measures such as R, U, K, k-values, Kws (Kilowatts per square meter per hour), or BTUs. However, the U-value is the best measurement of the rate of heat transfer through walls, ceilings, floors, and roofs.

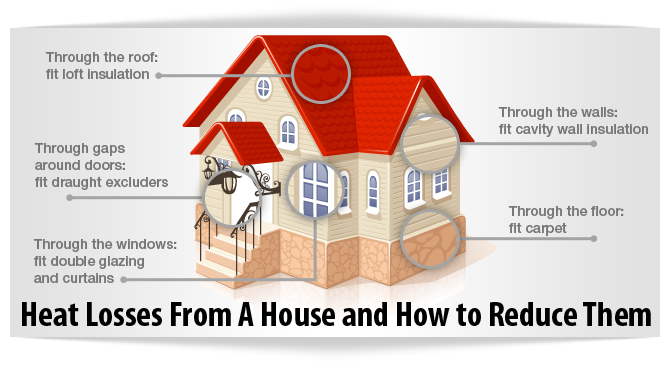

The general heat loss formula is Q=U*A*ΔT. U refers to the thermal insulation material used to build the structure, A is the area of the structure, and ΔT is the difference in temperature between the inside and outside of the building. To measure the total heat loss of a building, each area of the building should be divided into sections based on the U value of the material used and then added together to get the total. This typically includes walls, windows and doors, roof, and floor. If one area of the building has parts with different U values, they should be broken out into their own category.

As a professional insulation distributor, ECOIN offers you various solutions to reduce heat loss and improve the thermal efficiency of your project. Moreover, we offer glass wool and mineral wool insulation materials of high R-value and low U-value.

For fiberglass insulation products, click: Ecoin Fiberglass Insulation

For mineral wool insulation products, click: Ecoin Rock Wool