Cutting insulation material is an essential step in improving energy efficiency and reducing energy costs in a home or building.

Ⅰ. How to cut fiberglass insulation?

1.Tools for cutting fiberglass insulation

*Utility knife-A utility knife is the most essential tool for cutting fiberglass insulation. It is the best choice for making precise, shallow cuts in the insulation, such as score marking on the material. It is equipped with a retractable blade that allows you to easily control the cutting depth and make clean, even cuts. It is also the safest tool to use because it is not as sharp as other fiberglass cutting tools.

*Carving knife-A carving knife can be used to cut thicker pieces of fiberglass insulation. It is relatively sharp and can be used to cut through thicker layers of insulation. It is also helpful for making curved cuts or reaching into tight spaces. However, it is important to be extra careful when using a carving knife as it can cause serious injury if not used properly.

2. Steps for cutting fiberglass insulation

Step 1. Measure the material-To avoid damaging the floor underneath, us a sheet of plywood for cutting fiberglass insulation. If your structure doesn’t have a floor yet, just roll out the fiberglass material directly on the subfloor. Then Use a tape measure to determine where to cut the fiberglass and mark these measurements with a permanent marker.

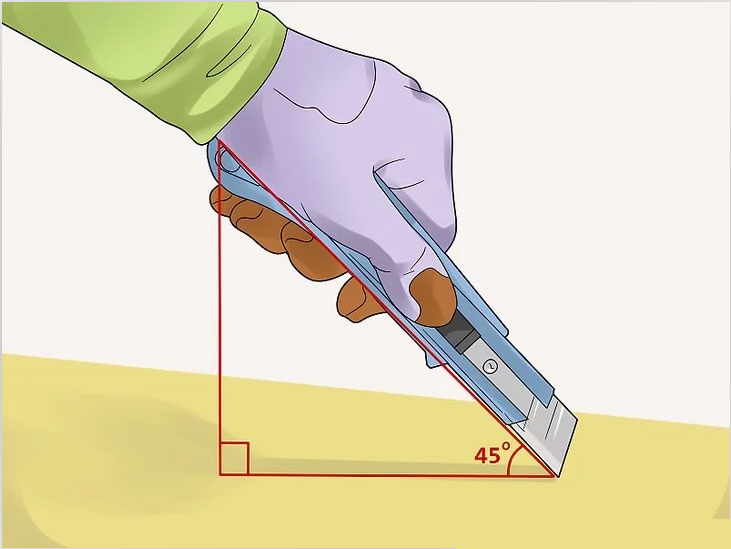

Step 2. Mark with a utility knife- Position a wooden board next to the measurement mark and compress it onto the fiberglass material. Hold a sharp utility knife at about a 45-degree angle over the mark and pull the blade to make a cutting line on the material.

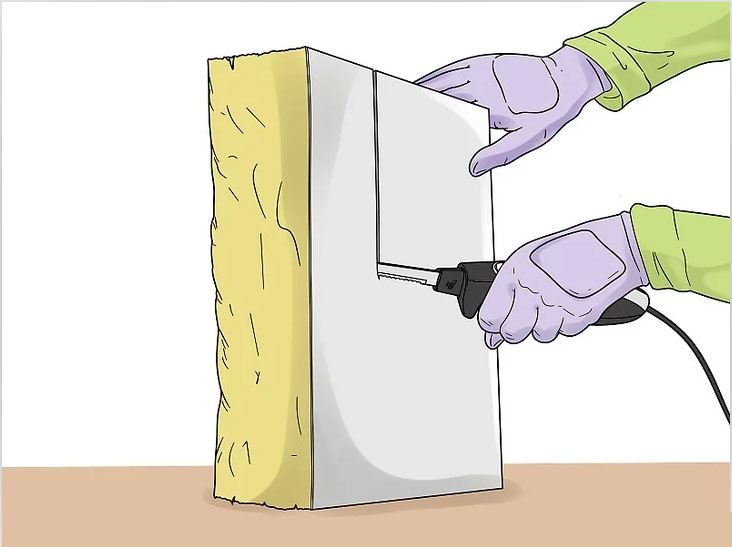

Step 3. Cut with a carving knife-Stand the fiberglass material up so that it’s easy to access the spot of cutting. Then position a carving knife perpendicularly to the material and hold the blade steady as it cuts through the insulation.

Tips- There’s a much easier way: you can use a piece of plywood to make an L-shaped straight edge; then press the edge on the fiberglass material and make the cut along the straight edge by only using a utility knife. In this way, you can skip the step 3.

Step 4. Trim with shears –Use a sharp pair of heavy-duty metal shears to trim the margins of the material.

Ⅱ. How to cut mineral wool insulation?

1. Tools for cutting mineral wool

Mineral wool has a matted-wool texture that’s coarser and denser than fiberglass. For this reason, regular knives or scissors are not suitable for cutting mineral wool. Compared with regular utility knives, serrated kitchen knives or construction knives are more appropriate for cutting mineral wool.

*Serrated drywall knife– A serrated drywall knife is an essential tool for cutting mineral wool. It is designed with a serrated blade that makes it easy to cut through the material quickly and accurately. The blade is usually made from durable steel and is coated to help prevent rust and corrosion. This type of knife is ideal for making precise cuts on drywall, insulation, and other materials. Its ergonomic handle provides a comfortable grip, making it easy to work with for extended periods. Whether you are a professional or a DIY enthusiast, investing in a serrated drywall knife can make any job involving cutting mineral wool easier and more efficient.

*Serrated bread knife– Though a serrated bread knife is a kitchen utensil, mainly used to cut through hard surfaces like crusty bread and cakes, it’s also ideal for cutting mineral wool. With its multi-functional blade, a serrated bread knife is a perfect tool for slicing through hard surfaces with ease and precision. Besides, its handle is also designed to provide maximum comfort and control.

2. Steps for cutting mineral wool

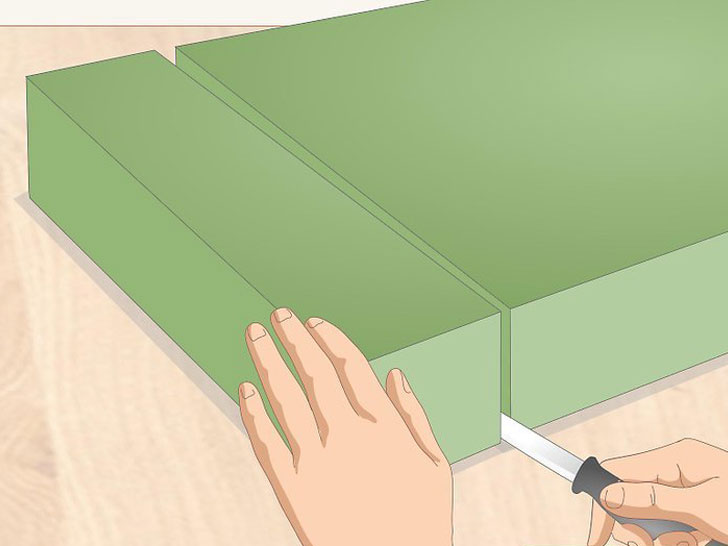

Step 2. Cut with a knife- Unlike cutting fiberglass insulation, cutting mineral wool insulation is simple: just press the material against the floor with one hand and cut the material with the other hand.

Mineral wool material has a very soft, fibrous texture, which is very similar to that of bread. A serrated bread knife or drywall knife can cut it through easily. Besides, an electric knife is also suitable for cutting mineral wool insulation. It’s worth mentioning that a knife with a straight blade isn’t recommendable as its straight blade tends to dull quickly while cutting the material.

Ⅲ. How to cut foam board insulation?

1. Tools for cutting foam insulation

Utility knife-As we mentioned before, a utility knife is a must-have tool for a wide range of projects: when it comes to cutting foam insulation, a utility knife is an ideal tool. Its sharp and durable blade is able to precisely and easily cut through the foam rubber sheet, allowing for neat and accurate cuts. Additionally, the sharp blade of the utility knife is made to last, meaning it can be used multiple times without losing its sharpness. This makes it a cost-effective option for cutting foam insulation.

Other types of knife with a thin, sharp blade-Apart from the utility knife, a knife with a thin and sharp blade can also be used for cutting foam insulation: when looking for the best knife for cutting foam insulation, you should consider the size, weight, and sharpness of the blade. The size should be appropriate for the job, and the blade should be light enough to make precise cuts.

2.Steps for cutting foam insulation

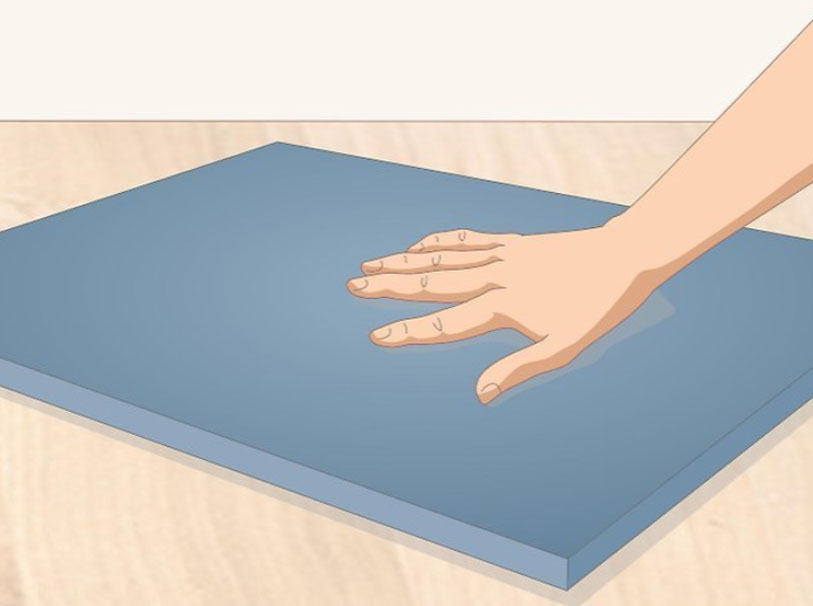

Step 1. Stabilize the foam-Set the foam atop a stable and protected surface. Press down slightly on the foam to hold it in place. Sketch guidelines on the foam with a permanent marker.

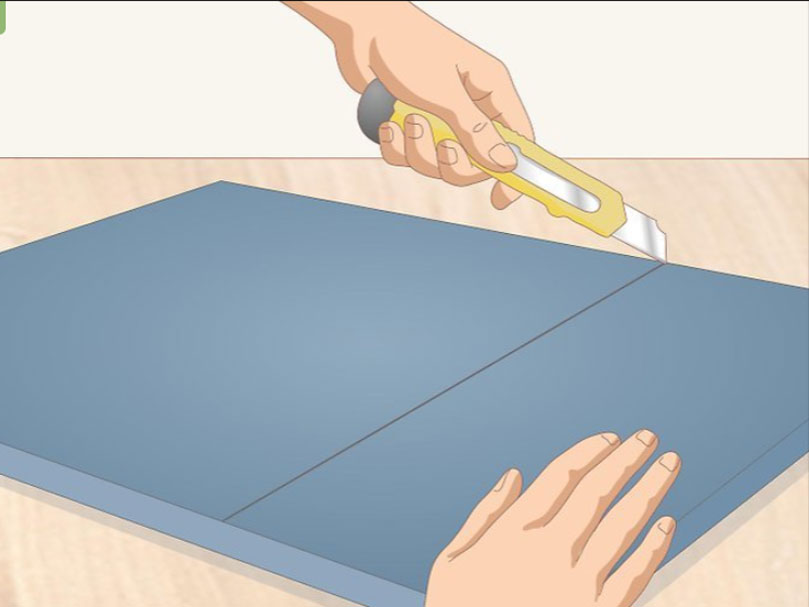

Step 2. Cut with a knife-For cutting foam insulation, the tools vary depending on the types of material.

For a thin foam sheet-Use a utility knife to cut foam rubber up to 1 in (2.5cm) thick: First cut the foam with light pressure to score it; then slice the foam rubber again until the material is cut through.

For a thick foam sheet- Select a thin, sharp blade for foam up to 4 in (10 cm) thick. Hold the knife flat against the top of the foam if you’re cutting through it. Slice through the foam to complete the cut.

Cut with a bandsaw- While cutting the foam rubber with a bandsaw, it’s necessary to wear safety gear. And set up the bandsaw according to the manufacturer’s instructions.

By the way, if you want to buy insulation materials, ECOIN might be your best choice. Mineral wool insulation, fiberglass insulation and rubber foam insulation materials are our star products. Please feel free to ask us. The detailed information is the following: