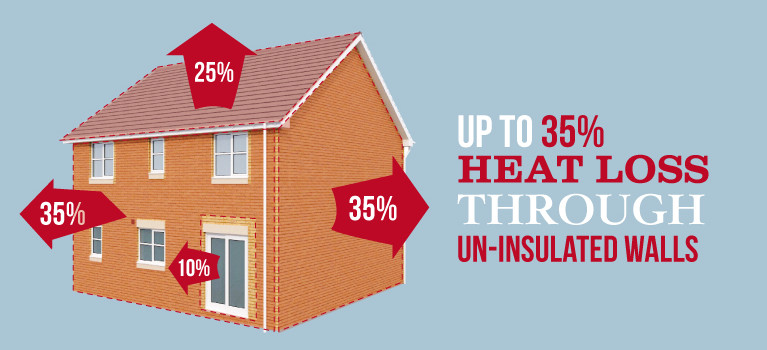

To ensure energy efficiency in your home or a commercial building, it’s essential that the construction should be insulated from the roof to its foundation. This means that wall thermal insulation is vital. Wall insulation helps to reduce the house’s heating and cooling costs; meanwhile, it also makes the appliances inside (such as washing machines, etc.) more efficient.

Ⅰ. Is wall insulation necessary?

There are various types of wall thermal insulation: batts, blankets, foam boards, and blow-in fibers, etc. All these wall insulation materials are vital for homes or buildings: they save energy, reduce heating and cooling bills, control noise, and even reduce condensation.

Efficient heating & cooling

By stopping the flow of heat into and out of the wall, wall thermal insulation materials keep both heat and air conditioning in the house. This means that your HVAC system will not have to work as hard and your energy bills will be lower: wall thermal insulation enables you to save up to 40 percent in heating and cooling bills.

Improved moisture control

Whether it’s fiberglass or mineral wool, most of these insulation materials are highly hydrophobic. This property helps to prohibit the growth of mildew inside the walls, Moreover, a vapor-resistant membrane attached to the wall insulation reduces condensation of moisture caused by daily activities like bathing, cooking, etc.

Fireproof

In a building, fire safety is fundamental as it implies the safety of building occupants, and the structural integrity of the building. It’s essential to prevent the spread of fire and ensure that no toxic smoke is released.

Most types of wall insulation materials are non-combustible and of high melting temperature: for example, the melting point of mineral wool for insulation is more than 1000℃. These wall thermal insulation materials don’t only keep the heat but also provide a fireproof layer. To know more about the fire resistance of insulation materials, please click: What Type of Insulation is More Fireproof?

Noise reduction

As we mentioned above, wall insulation is multi-functional and one of these functions is noise reduction. Insulation walls can reduce annoying sounds from outdoors and reduce sound carrying from one room to another, which is essential for both residential houses and commercial buildings. Particularly, with insulated interior walls in your home, there’s less worry about whether the TV’s too loud as the sound won’t carry too much.

Ⅱ. What is the best way to insulate a wall?

Wall thermal insulation products vary in materials and forms. Fiberglass, foam board, and mineral wool for insulation can be applied for wall insulation. And in terms of their forms, the main types are the following:

*Batts or blanket insulation-They are easy to install and offer an effective solution to reduce heat transfer. For this reason, these are the most popular types for insulating both internal and external walls.

*Loose-fill insulation-This type of wall insulation is also known as blown-in insulation. It’s made of loose material and can be blown into tiny cracks and crevices in the room. Its ability to seal tightly makes it a much better and more energy-efficient solution than batts or blankets. Loose-fill insulation is suitable for cavity wall insulation.

*Foam board insulation-Compared with fibrous insulation materials, foam boards offer more compressive strength for relatively less thickness.

The type of wall insulation materials depends on the application of wall insulation. Generally speaking, the main applications of wall thermal insulation are the following:

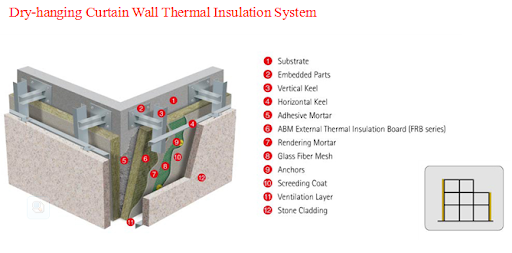

1. External wall insulation

External wall insulation refers to attaching a layer of insulation wall material to the exterior side of the wall: firstly, the wall thermal insulation material is fixed on the substrate; then a mesh or fixing anchors are applied to fasten the material. Ultimately, this wall insulation will be covered by a special type of render or cladding: the finish can be smooth, textured, painted, tiled, paneled, or pebble-dashed.

The benefits of external wall insulation are the following:

- Prevents the outside ambient temperature from interfering with the inside conditioned air.

- Reduces condensation on internal walls, which might be caused by temperature differences.

- Improves weatherproofing and sound resistance, which consequently helps to increase the lifespan of the wall.

- Fills cracks and gaps in the brickwork.

In summary, an external wall insulation system (also known as EWIS) is a thermally insulated, protective, decorative exterior cladding procedure involving the use of various insulation materials, such as mineral wool for insulation, foam boards, etc.

As a professional mineral wool manufacturer, ECOIN’s main products for external wall insulation are Rockwool External Wall Insulation Boards, and Rockwool Curtain Wall Insulation Boards. It’s worth mentioning that curtain wall is a special type of exterior wall: it’s hung on the exterior of the building and bears no loads. This curtain wall is widely used in commercial buildings as an exterior cover or decoration. ECOIN also offers wall insulation for curtain walls.

An external wall insulation system (or EWIS) is a thermally insulated, protective, decorative exterior cladding procedure involving the use of expanded polystyrene, mineral wool, polyurethane foam, or phenolic foam, topped off with a reinforced cement-based, mineral or synthetic finish and plaster.

2. Internal wall insulation

Internal wall insulation refers to fixing the wall insulation layer to the internal side of the wall. Generally, there are two ways of internal wall insulation: one method is to fix rigid insulation boards on the wall by using insulation pins; the other way is to build a stud frame and fill in the space between studs with insulation batts.

Since external walls are already insulated well, do interior walls need insulation?

The benefits of internal wall insulation are the following:

- Reduces heat transfer from room to room, which makes heating and cooling quicker, easier to maintain, and less costly.

- Prevents the temperature change from cracking drywall.

- Is cheaper to install than external wall insulation.

Ⅲ. What’s the difference between cavity wall insulation and solid wall insulation?

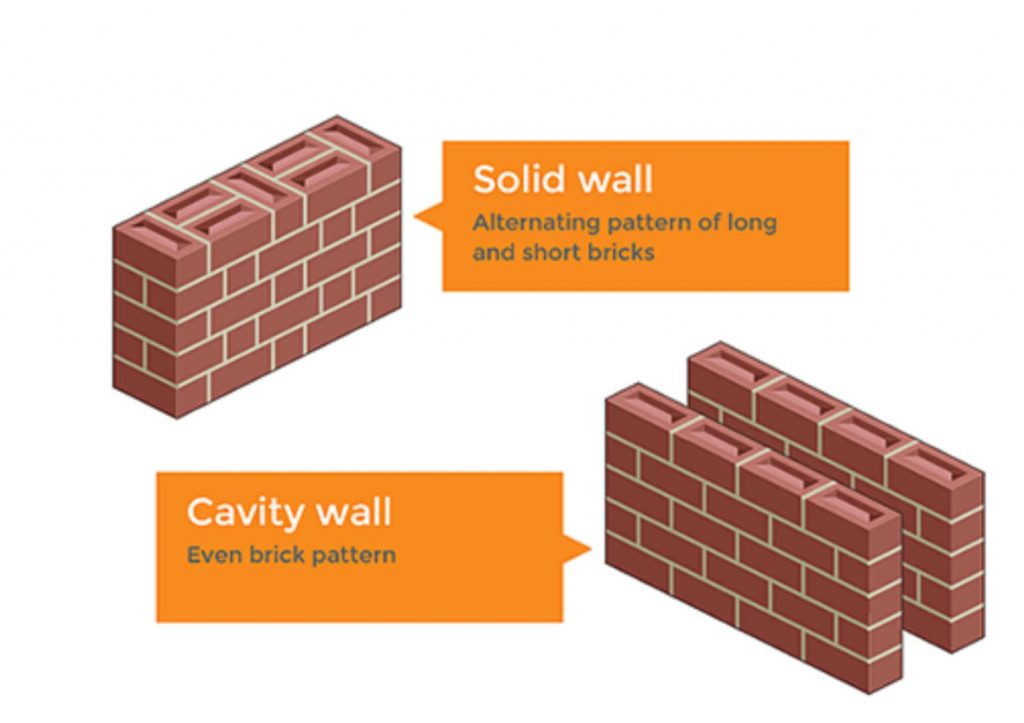

Whether it’s external wall insulation or internal wall insulation, all we mentioned above are solid wall insulations. Solid walls are external walls of a building that have no cavities or gaps.

However, nowadays more and more buildings are constructed with cavity walls. Cavity walls are made up of two layers with a cavity between them. Originally, these cavity walls were designed to prevent rainwater from sweeping through the walls into the building; at the present, cavity walls are filled with insulation material to improve the overall thermal insulation of the building.

Cavity wall insulation

Cavity wall insulation means filling in the gap with wall insulation materials. Generally, there are two types: one way is to install rigid board insulation materials in place during the construction; the other way is to blow insulation fibers into the cavity after the construction.

Nowadays, cavity wall insulation is widely used for insulating residential houses. Though external wall insulation might decrease your energy bill drastically, its cost is much higher than cavity wall insulation. This makes cavity wall insulation a better choice for a shorter payback time.

Solid wall insulation

As we mentioned before, both external wall insulation and internal wall insulation mainly refer to solid wall insulation, which involves rigid insulation boards or insulation batts.

Compared with cavity wall insulation, solid wall insulation might be more expensive. However, solid wall insulation has a better insulation value: the insulation value depends on the heat resistance of the material and the thickness of the insulation layer; however, the thickness of cavity wall insulation material is limited to the width of the cavity while the solid wall insulation has no such limit. This means that if you want to further improve the total insulation value, you might also need to place an extra layer of internal wall insulation in addition to the cavity wall insulation.

Ⅳ. What is a good insulator for walls?

How to choose the best material for wall thermal insulation? To answer this question, you need to take into account the following factors: the property of the material itself, such as R-value; and the applications more specifically, such as whether it’s used for external wall insulation or internal wall insulation.

For external wall insulation

For external wall insulation, the material is usually fastened to the property’s exterior through insulation fasteners. The main materials suitable for this application are the following:

| Mineral wool board | Foam rubber sheet |

| ● Low thermal conductivity ● High durability ● High level of fire resistance and moisture resistance ● Can be adhered or mechanically fixed to the wall | ● Low thermal conductivity ● Lightweight and high compressive strength ● High level of chemical and fire resistance ● Easy to be adhered or mechanically fixed to the wall |

For internal wall insulation

For internal wall insulation, the material can be either fixed directly on the substrate or filled into the space between studs. Both fiberglass and mineral wool for insulation are suitable choices.

| Mineral wool boards/batts | Glass wool boards/batts |

| ● Low thermal conductivity ● High density for sound insulation ● High level of fire resistance and moisture resistance ● Easy to cut, move and fit into place | ● Low thermal conductivity ● Contains no asbestos, which means more environmentally friendly ● Less expensive |

For cavity wall insulation

As we mentioned before, there are two ways to insulate the cavity wall: one is to build the insulation boards inside the cavity during the construction; the other is to fill the insulation materials into the gap after the construction. For the latter type, both loose-fill insulation and spray foam insulation are suitable.

| Loose-fill insulation | Spray foam insulation |

| ● Grate variety of materials: rockwool, fiberglass and cellulose etc. ● Easy to be blown into cavity walls without reducing space in a room ● Be treated to be resistant to fire, mould. | ● Mainly made up of two chemical components: polyurethane and isocyanate. ● Offers air-tight seal and reduces air leakage. ● No need to install a vapor barrier. |