I. What is a vapor barrier of insulation?

A vapor barrier, or insulation vapor barrier, is generally a thin plastic or paper sheet. This material serves as a moisture barrier for insulation, helping to keep moisture from entering the materials and causing water damage. Installed along, in, or around walls, ceilings, and floors, vapor barriers are typically used in new construction projects, with gaps around pipes and other building materials. Vapor barriers are rated by the “moisture vapor transmission rate,” which measures how completely impermeable the material is. A true vapor barrier is rated 0.0 perms, while a vapor retarder is slightly porous but still provides some protection from moisture. Vapor barriers and retarders help improve energy efficiency by preventing air leakage from exterior walls, and because they are so thin, they don’t add much weight to the structure.

Insulation and moisture barriers for insulation are two different materials that should be used together for maximum protection and thermal insulation in your home. Insulation is a thicker material than a moisture barrier for insulation and is usually made with fiberglass, polyester, wool, polyurethane, or cotton batting. It’s wrapped around studs and joists to fill any voids left behind when the drywall is installed, preventing air movement between your home’s interior and exterior walls. An insulation vapor barrier is a thin material that provides a shield between the exterior walls and your home’s insulation, keeping the insulation dry in case of moisture infiltration. Both products are essential for creating a comfortable, energy-efficient home environment.

Ⅱ. When a vapor barrier for insulation is needed?

When to use a Vapor Barrier with Insulation? Generally speaking, there are two main factors:

Types of Insulation Materials:Depending on the type of insulation material used, a vapor barrier may be needed. For example, most closed-cell spray foams become a vapor retarder at around 1-1 ½”. Fiberglass batt and rolled basement or building insulations are often made with a facer designed to be a vapor retarder. Blown-in walls usually require a poly or a smart membrane vapor barrier for protection.

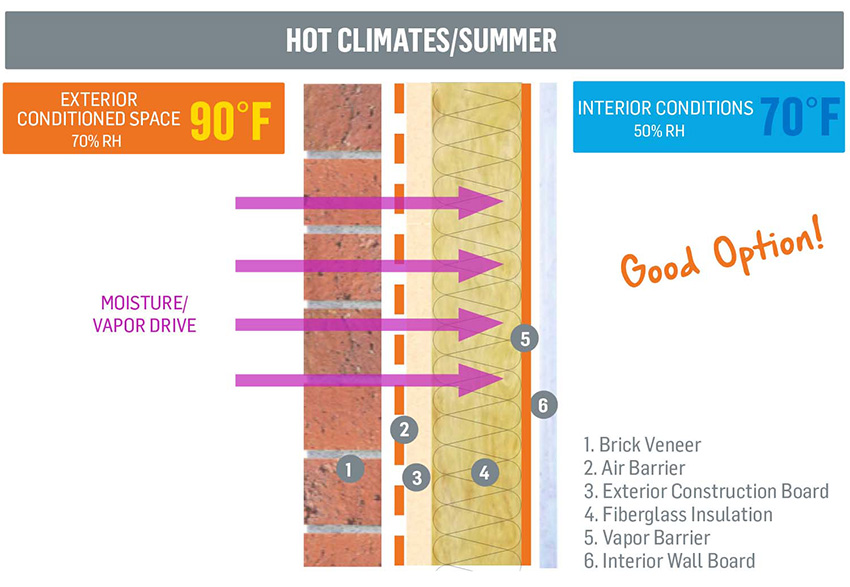

Climate Conditions:Vapor barriers protect against mold and rot inside structures by preventing condensation and moisture from building up. If a home is being built in a very humid climate, a vapor barrier can be an essential source of protection. Therefore, the climate zone typically determines whether the vapor barrier is needed and how to install it. Generally, in cooler climates, the vapor barrier should be on the interior of the insulation, while in warmer climates, it should be installed on the exterior.

Ⅲ. How to install a vapor barrier for insulation?

As we mentioned before, the insulation vapor barriers are mainly used for wall insulation, roof insulation, and insulation in crawlspaces.

*How to install a vapor barrier on the wall?

a. The insulation vapor barrier on the surface of the wall

In order to prevent moisture from penetrating a structure, an insulation vapor barrier should be installed on the side of the wall that experiences hotter temperatures and moister conditions, such as the inner surface in colder climates or the outer surface in hot, humid climates. However, having moisture barriers on both sides of a wall should be avoided as this may prevent the wall cavity from drying out in one direction. Besides, the installation of insulation vapor barriers must be done in conjunction with sealing airflow gaps in walls and ceilings, as well as along floor surfaces, in order to ensure proper moisture protection.

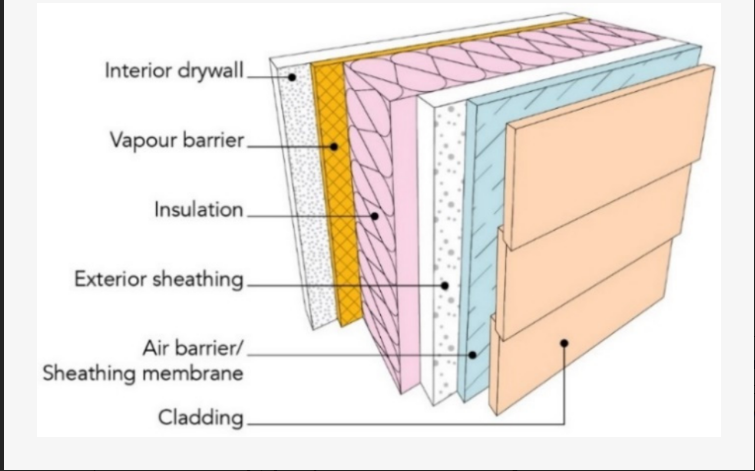

b. Insulation vapor barrier in the cavity wall

Insulation vapor barriers are used in traditional cavity wall construction to help protect the insulation from moisture damage. A moisture barrier for insulation is placed between the cavity insulation and the inner masonry skin to act as a protective barrier against the passage of moisture. The insulation vapor barrier is essential in helping to keep the insulation dry and maintain its R-value. It also helps to reduce thermal bridging and can help protect against mold and mildew growth. Properly installed and maintained insulation vapor barriers can be an effective way to keep heat in and moisture out of your home.

*How to install a vapor barrier on the roof?

An insulation vapor barrier is an important component of a metal roof insulation system that helps to prevent the formation of condensation. The vapor barrier helps to keep warm, moist air from penetrating the roofing system and coming in contact with the cold surface. This helps to reduce the risk of premature corrosion and mold formation. The insulation vapor barrier should be installed on the warm side of the roof system to act as a moisture barrier for insulation. Once the insulation vapor barrier is in place, the roof system should be insulated with materials such as fiberglass or cellulose to help regulate the temperature within the roof system and prevent condensation. The insulation should be properly installed to ensure that it completely fills the attic spaces and all gaps between the ceiling and roof deck.

*How to install a vapor barrier in the crawlspace?

Installing an insulation vapor barrier in a metal crawlspace is an important task to ensure the space stays dry and free from moisture. These sheets of vapor barrier should be secured to the walls and support columns with double-sided butyl tape, and around the perimeter of the crawlspace, the plastic sheeting should be extended at least 6 inches up the walls and secured in place. Improving cross ventilation through the crawlspace is also a key factor in preventing residual moisture from being trapped in the space.

Note: It is not necessary to install a moisture barrier for insulation on both sides of the insulation material. When a vapor barrier is installed incorrectly, it can actually trap moisture inside the wall. To avoid this, it is best to make sure that the wall is porous and can “breathe”, which will make it less likely to suffer from long-term moisture problems. For this reason, it’s especially important to avoid installing a vapor barrier on both the inside and outside walls, as this will prevent the wall from being able to breathe.

Ⅳ. I Insulation materials with vapor barriers.

Faced insulation is an ideal choice for home insulation, as it has a paper or plastic vapor barrier or retarder attached to one side of the insulation, which helps to block moisture from permeating the walls and ceilings. This makes it an excellent choice for humid locations, like coastal cities. Additionally, faced insulation is easier to install than unfaced insulation, as it is held together by the paper vapor barrier, allowing it to be rolled, moved, and stapled without falling apart.

However, faced insulation is more flammable than unfaced insulation due to the paper vapor barrier, and therefore cannot make the same noncombustible claim. Therefore, faced insulation is typically used in exterior walls and attic ceilings to prevent water from entering the home, while unfaced insulation is used to improve the heat retention ability and reduce the risk of fire.

As a professional faced insulation manufacturer, ECOIN offers faced insulation products with different types of facings, which mainly are the following:

*Foil-faced insulation materials

Foil-faced insulation materials are gaining increasing popularity due to their excellent ability to provide both a moisture barrier and thermal insulation. The foil facing, usually composed of aluminum, is a highly reflective material that prevents heat transfer, while also providing a durable, waterproof layer that acts as a moisture barrier for insulation. Our main products include foil-faced fiberglass insulation and foil-faced mineral wool insulation materials, both of which are designed to provide superior protection against air and moisture infiltration and excellent thermal performance. With their superior durability and long-lasting protection, these foil-faced insulation materials are the perfect choice for any project.

For more information, please click:

*Kraft-faced insulation materials

Kraft-Faced Insulation is a type of formaldehyde-free fiberglass batt insulation that is designed to keep the air quality in your home clean and fresh. With a paper vapor barrier on the paper-facing side, this insulation type is perfect for preventing mold, mildew, and allergens and is one of the most affordable insulation options on the market. Kraft-Faced Insulation is great for installation in exterior walls, basement walls, and attic ceilings, as it can help keep moisture and water vapor away. The insulation comes in various shapes and sizes, making it an ideal choice for different areas of your home.

PVC-coated insulation materials

PVC Coated Insulation is a great choice for insulation vapor barrier and it offers many benefits. Our star product, PVC-coated fiberglass insulation, is widely used for roof insulation and is known for its durability and strength. This insulation material is also highly effective in protecting against moisture and condensation, making it a great choice for roof insulation. It is also lightweight, making it easier to install and maintain. Moreover, PVC-coated fiberglass insulation is resistant to corrosion and fire, making it a safe and reliable choice for roof insulation.

For more information, please click: Ecoin Fiberglass Insulation