Urbanization and climate change have created new difficulties for the contemporary lifestyle. Buildings are being constructed taller and closer together, often at a rapid rate. This can lead to an increased risk of fire hazards, as fires can spread more easily between closely located buildings.

For these reasons, fire protection is essential for a building or a house’s safety. And the most common materials for fire protection are rockwool fire barrier and fire-stopping rockwool.

Ⅰ. What is a rockwool fire barrier?

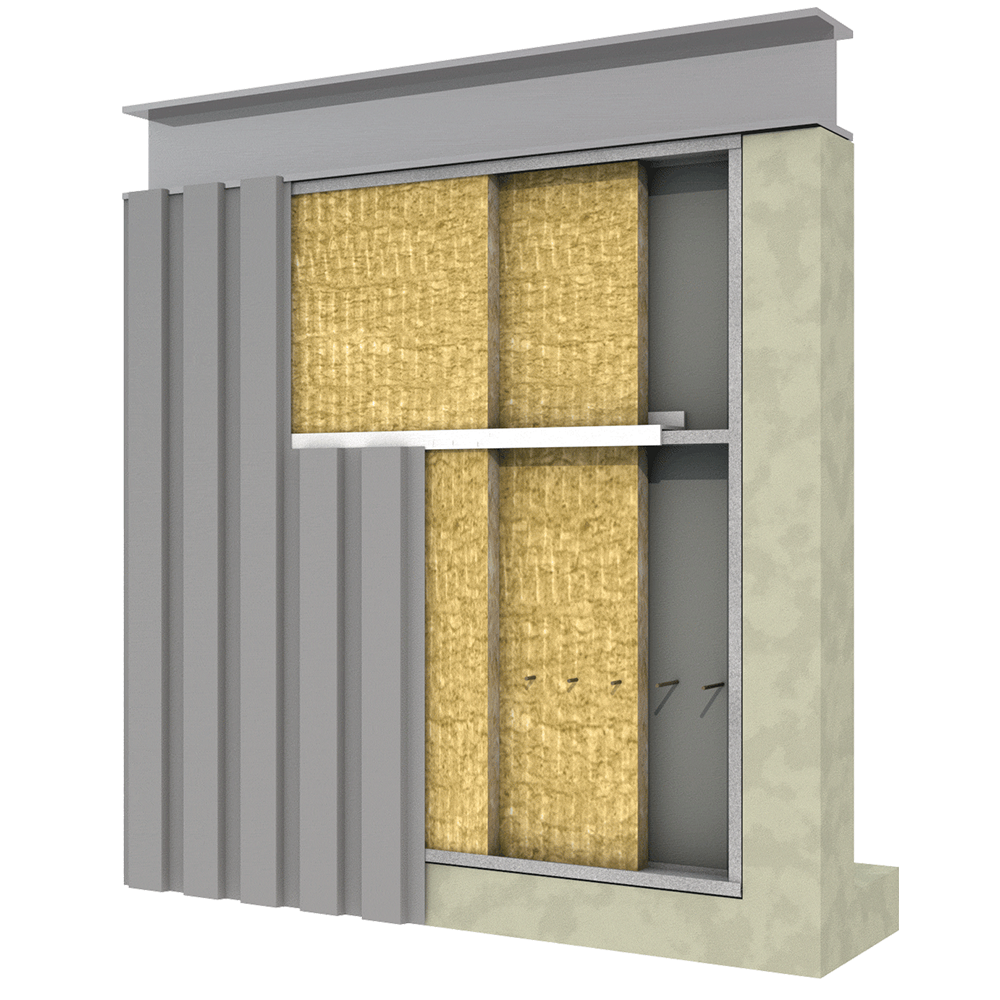

Rockwool fire barrier sets are an organic material external thermal insulation system used to prevent the spread of fire in large areas. Fire barrier zones play an important role in protecting the safety of buildings and providing more escape time. Fire Barrier systems have been developed to prevent the spread of flames, inhibit heat and smoke through concealed spaces in buildings, and improve sound reduction. More precisely, the rockwool fire barrier is a construction, not just a smoke curtain. This rockwool cavity barrier is used to close off concealed spaces against the penetration of smoke or flame, or to restrict the movement of smoke or flame within such a space. These barriers are essential in forming a complete seal between different areas of a home, as without them, experts say that fires can spread five to ten times faster through a building.

What is a rockwool fire stop?

Rockwool fire stop, also known as fire-stopping rockwool, is a seal around openings and between joints, helping to maintain the fireproofing of a wall or floor assembly and preventing the spread of fire and smoke. Moreover, it closes a gap or imperfection in a fire-resisting element of a structure or compartment lining. Consequently, it should have at least the same fire resistance as the function requirement in which they are located.

In other words, fire-stopping rockwool can be used to close a cavity and achieve fire cavity barrier functions. However, a fire cavity barrier is not considered a fire stop unless it is designed for that function.

What is the difference between rockwool fire barrier and fire-stopping rockwool?

Cavity fire barriers and fire stops are two types of passive fire protection that can impede the spread of flames and smoke in a fire. While they can sometimes be used interchangeably, there are still distinctions between them:

A rockwool cavity barrier fills concealed internal gaps within walls, ceilings, and other parts of a building.

On the other hand, fire-stopping rockwool is typically used to fill visible gaps around openings or joints in fire-resistance rated walls.

Ⅱ. Why choose rockwool materials as fire protection?

Rockwool material is ideal for fireproofing. It is made from basalt rock and recycled slag, which are both naturally occurring materials that are melted and spun into fibers. Rockwool is non-combustible, meaning it will not burn or support combustion. It also has excellent thermal insulation properties, which help to slow the spread of fire and smoke. Additionally, Rockwool is lightweight and easy to install, making it an ideal choice for fire barriers in buildings.

Properties of rockwool

- The rockwool material is engineered using a volcanic process, which provides high resilience

- Like natural stones, the rockwool is non-combustible

- Rockwool material can withstand temperatures exceeding 1000°C

- Even under a high temperature, the rockwool material maintains strength and dimensional stability

- Rockwool material does not produce toxic smoke

Moreover, ECOIN’s rockwool fire barrier also ensures optimal thermal insulation.

Advantages of rockwool fire barriers

- All our rockwool fire barriers are made from robust and durable stone wool.

- Its fire-resilient properties mean it can withstand temperatures above 1000°C and retain its shape, strength, and performance levels. The melting point of our rockwool cavity barriers is >1150℃

- Our rockwool fire barriers are especially effective in slowing the spread of fire, with fire endurance of 1-4 hours, which significantly increases the time to escape for occupants in the building.

- Our rockwool fire barrier does not release toxic smoke when exposed to fire, which is a dangerous risk to occupants.

- Our fire-stopping solutions range of non-combustible steel frame insulation includes various products suitable for application in structures of different shapes and sizes.

- ECOIN offer rockwool fire barriers in different shapes and sizes for different applications. Our rockwool cavity barriers are suitable for most steel frame designs and easy to install.

For more details about our rockwool fire barriers, please click: Ecoin Rockwool Fire Barrier

Ⅲ. What are rockwool fire barriers used for?

As we mentioned before, rockwool fire barrier is a type of insulation material used to protect buildings or houses from fire: the rockwool fire barrier can be used in walls, ceilings, and floors to provide a fire-resistant barrier between two areas; the rockwool cavity barrier can also be used in attics and crawl spaces to provide additional fire protection. Moreover, the rockwool fire barrier is also used in industrial applications. More specifically, the main applications are the following:

Steel structure protection

The safety of those occupying buildings with steel frames is of paramount importance. To reduce the risk of collapse due to fire, structural steel fire protection is essential. Steel can start to soften at temperatures as low as 425°C, and lose half of its strength at 650°C, although it does not melt until it reaches 1,300°C. Unfortunately, fires can reach temperatures far higher than this, so fire protection for steel beams and columns is necessary to slow down the spread of fire and protect those inside. This is where rockwool fire barrier with a high melting point (>1150℃) is required.

Ductwork protection

The ductwork in many large buildings is essential for providing and removing hot and cold air to ensure a comfortable environment for those inside. However, these systems can also provide a convenient route for fire to spread. To reduce the risk of fire, the rockwool fire barrier can be used in heating, ventilation, and air conditioning (HVAC) systems. This helps to slow down or even stop the passage of flames and smoke throughout the building. These rockwool slabs create a barrier between ducts, further reducing the risk of fire spread.

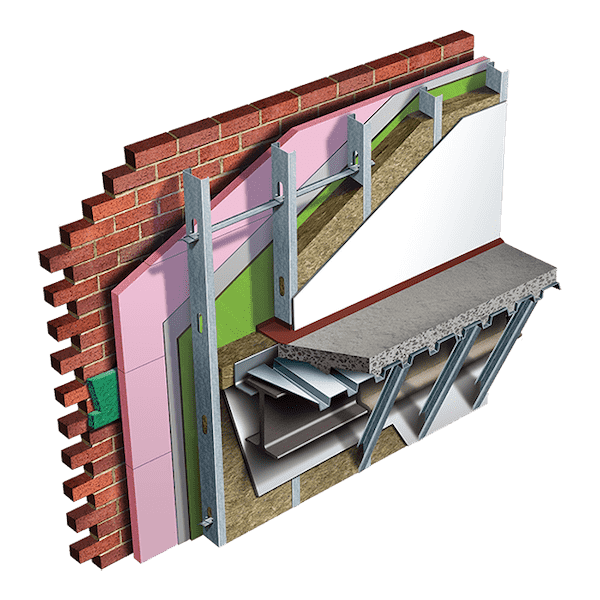

Fire barrier systems

As rockwool fire barriers can be used in so many areas, the concept of “fire barrier systems” have been risen by many rockwool manufacturers:

A fire barrier system is a type of passive fire protection system that is designed to contain and prevent the spread of fire. Certainly, the rockwool fire barrier is the core of the whole system. Apart from that, the system is also composed of fire-resistant materials such as drywall, concrete, and steel. These fire barriers are used in buildings to protect occupants from the spread of fire and smoke, as well as to protect the structure itself from damage caused by fire.

Ⅳ. Installation of rockwool fire barriers

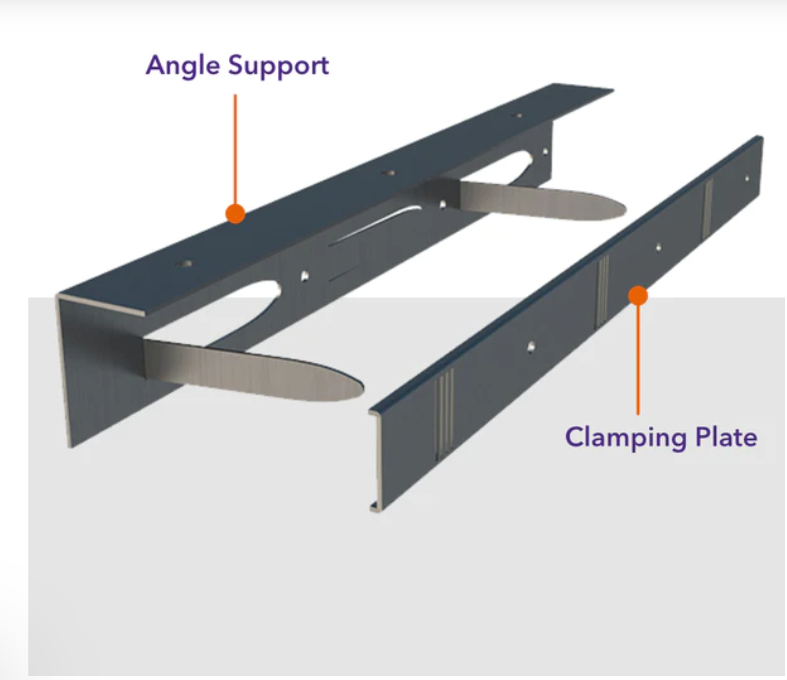

In summary, Rockwool fire barrier installation involves attaching the fire barrier to the wall or ceiling using screws, adhesive, or other fastening methods and then sealing the edges with a fire-resistant sealant. More specifically, the main steps of installation are the following:

1) Purchase the appropriate type of rockwool fire barrier for the application.

2) Measure the area where the fire barrier will be installed and cut the rockwool to size. The insulation knife or saw is usually the most popular tool for cutting.

3) Secure the rockwool to the wall or ceiling using appropriate fasteners. The angle support and clamping plates are the most common fasteners of rockwool fire barriers. They are designed to hold rockwool fire barriers in place on walls, ceilings, and other surfaces, preventing them from slipping or shifting.

4) Install any additional components such as fire-resistant tape or fire-resistant drywall.