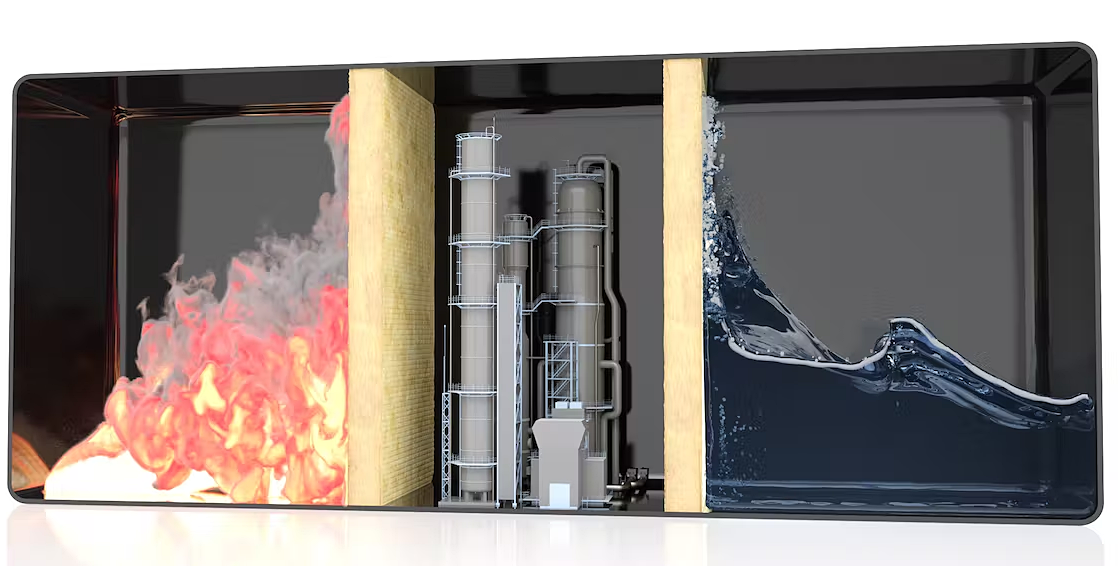

Compared with thermal insulations for constructions on land, offshore marine insulation requires more: on the one hand, it’s not only required to be effective in thermal insulation, but also in resistance to fire, moisture, and sound; on the other hand, it should meet marine regulations made by international authorities.

Ⅰ. Why do we need rockwool marine insulation?

Whether it’s freight ship, commercial fishing ship, cruise liner, or oil rig, rockwool marine insulation is indispensable for the following reasons:

Temperature regulation-A better temperature regulation helps to maintain a comfortable environment for people to travel and for equipment to work under a more suitable condition.

Energy efficiency-By trapping heat in its mineral wool fibers, rockwool marine insulation helps reduce excess energy consumption. As we mentioned above, rockwool marine insulation helps to regulate the temperature on the offshore platforms, which reduces reliance on heating and cooling systems and, therefore, saves money. Besides, heat loss impacts a lot in many industrial applications on ships or oil rigs, such as liquid transmission through pipelines, etc. For these reasons, rockwool marine thermal insulation is indispensable.

Fire safety-For both crew and passengers on ships or other offshore platforms, securing the highest level of fire safety is crucial. Unlike residential houses or commercial buildings, crew and passengers may be miles from a safe, land-based evacuation point. Thus non-combustible materials are imperative on offshore platforms to guard against fire outbreak. In an onboard environment, where the crew has very limited options for egress, marine insulation is the best choice for fire resistance.

Noise reduction- It’s inevitable to be exposed to loud noise levels from the elements outside or from operating engines on ships or oil platforms. These sound vibrations can cause issues ranging from comfort to personal well-being and safety. Besides, these vibrations also impact structural safety. For this reason, rockwool marine offshore insulation is indispensable: its dense composition of mineral wool fibers stops noise from penetrating surfaces and holds it in air pockets.

Structure integrity-Rockwool marine insulation helps to increase the structure’s stability and water resistance: its inorganic mineral fibers are highly water-resistant prohibiting mold growth. This combination of the benefits enhances the ship’s lifetime, minimizes the need for maintenance, and consequently contributes to saving your money in the long term.

To sum up, marine insulation is necessary for the safety and long-life service of ships and oil platforms. Besides, rockwool marine insulation also helps to create a healthy and comfortable onboard environment for people.

Ⅱ. What is marine insulation?

1. What is marine insulation?

As its name indicates, marine insulation is an insulation product that is rated for use in maritime applications. Traditionally, marine insulation mainly were cork-based products and mineral wool insulation products, also known as rockwool marine offshore insulation. Nowadays, thanks to the advancements in material science, many other types of material are also introduced to marine applications, such as fiberglass-based insulation materials, rubber materials, and aluminum-based insulation materials, etc.

Marine insulation can typically be found in the walls (bulkheads) and ceilings (decks) of a ship. And for this reason, marine insulation is also known as ship insulation or boat insulation. However, there are other uses for custom insulation, such as insulating equipment on offshore oil rigs, etc.

2. What makes marine insulation different from normal insulation?

Multi-function-As we mentioned before, marine insulation is indispensable in an onboard environment where there are few options for egress: marine insulation should yield thermal, fire, and acoustic insulation to be effective. In other words, marine insulation should be highly fire-resistant, and water-repellent while offering thermal insulation and soundproofing.

The marine regulatory compliance-Another distinguishing characteristic of marine insulation products is its ability to withstand humidity and water. To meet these requirements, marine insulation must comply with a series of rules and regulations produced by various maritime organizations: International Maritime Organizations (IMO), flag states, agencies, regulators such as the United States Coast Guard (USCG), and classification societies such as the American Bureau of Shipping (ABS), etc.

Generally speaking, all ships must comply with the regulations set by IMO. These rules dictate thermal, fire, and noise insulation:

- IMO Safety of Life at Sea (SOLAS)-For self-propelled vessels over 500 gross tones are involved in international trade.

- IMO MODU Code-For mobile offshore drilling units involved in international operations.

Besides, many flag states have their own requirements for vessels. And many individual vessels are also classed with a marine classification society, whose rules are often aligned with the IMO regulations.

An understanding of these regulations, their areas of application, and their interrelationships are indispensable for the selection and installation of marine insulation.

3. Different types of marine insulation

Thanks to the advancement in material science, more and more new types of insulation materials are introduced to maritime applications. They are mainly the following:

Fiberglass insulation- fiberglass is resistant both to fire and chemicals. Compared with rockwool marine offshore insulation, it’s less expensive. However, it’s still water-permeable, which means that it will lose the effectiveness of thermal insulation when damp. Besides, it’s less durable than rockwool marine thermal insulation, offering little in the way of structural support to a hold.

Foam insulation-Foam rubber materials for marine insulation can be in different forms: spray, blocks, or sheets. Generally, closed-cell foam rubber is widely used for ship insulation. It has a high compressive strength and a high level of resistance to water. However, due to its closed-cell structure, its shock absorption ability is low. Besides, compared with mineral wool fibers, foam rubber is less durable and stable.

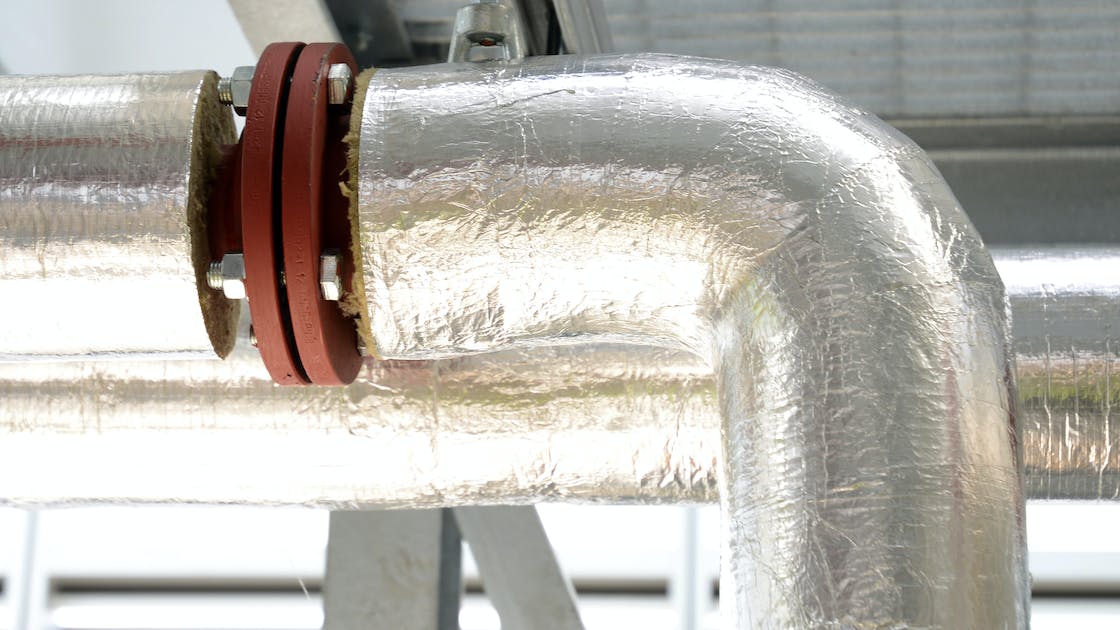

Metal jacketing-Metal jacketing is necessary for marine insulation: it doesn’t only protect and secure the insulation materials inside; but it also serves as an effective vapor retarder, preventing moisture migration to the duct or pipe surface. In an onboard environment, a high level of water resistance is crucial.

ECOIN offers different forms of metal jacketing to protect your marine insulation. For marine insulation, stainless steel metal jacketing is the most popular type.For more information, please click: Ecoin Stainless Steel Jacketing

For more information about aluminum jacketing, please click: Ecoin Smooth Aluminum Roll Jacketing

Mineral wool insulation-Compared with other insulation materials, rockwool marine thermal insulation has more advantages: its mineral fibers are more durable and offer a longer service life; its structure of high density offers better absorption of sounds and vibrations. More importantly, its inorganic texture impedes mold growth, which is essential for marine applications. This rockwool marine thermal insulation is widely used in insulating a vessel or an offshore rig.

As a professional marine wool supplier, ECOIN offers rockwool marine offshore insulation in compliance with marine regulations and different requirements. For more information, please click: Ecoin Rock Wool Marine Offshore Insulation

Ⅲ. Main applications of rockwool marine insulation

As a key factor on ships and other offshore platforms, the main applications of rockwool marine insulation are the following:

Thermal insulation of bulkheads & decks-To reach the optimum temperature while saving energy, rockwool marine insulation is very popular to insulate bulkhead panels and decks. For maritime applications, thermal insulation is a must for indoor climate and comfort.

Marine fireproof doors-To prevent fire outbreaks, it’s necessary to use mineral wool materials as insulation core in steel fire doors. Ship insulation stops the fire and prevents its spreading from one part of the vessel to another.

Marine engine noise reduction- As we mentioned before, sound vibrations may cause severe damage while spreading across the ship. Ship insulation helps to insulate all the noise coming from outside and from equipment on ships, in particular, from operating engines.

Marine exhaust insulation- Marine exhaust systems require is another sector where temperature regulation is required. A suitable working temperature helps the engine work smoothly providing its highest efficiency. Rockwool marine thermal insulation maintains hot exhaust gas at the right temperature.

Fuel line insulation-To ensure fire safety, it’s necessary to protect the fuel lines from getting hot. Besides, when the liquid fuel is converted into gas, the vapor lock might cause a loss of feed pressure to the fuel injection system. To prevent this, it’s essential to wrap the fuel lines with rockwool marine thermal insulation.

Ⅳ. How to choose rockwool marine offshore insulation?

There are various marine insulation materials to choose from. Each insulation product offers a unique set of properties and benefits. The selection of a particular type of boat insulation is dependent upon the part of the vessel of rig that is being insulated. However, there are still a series of selection parameters in common:

Fire resistance—a Top Priority

Unlike onshore operations, marine operations have limited options for egress when there’s a blaze. This makes fire resistance a top priority for marine insulation. Compared with other insulation materials, rockwool marine offshore insulation is made from a non-flammable material, with a high melting point. For this reason, rockwool marine insulation is an ideal choice for maritime applications. (To know more about fireproofing property, please click: what type of insulation is more fireproof?

Thermal properties-R-value is the main parameter to measure a material’s thermal property: the higher the R-value is of the material, the better thermal insulation effect it offers. The R-value of rockwool marine insulation usually remains stable throughout the entire lifespan of the building. This ensures stable and effective thermal insulation.

Moisture resistance- Saltwater presents an especially hostile environment for materials in the marine sector. According to an American report, more than a quarter (27%) of insulation failures occur in tubes and piping across components in the maritime and oil sector. This requires high water resistance from marine insulation. Rockwool marine insulation is made of inorganic fibers, which makes no place for mold growth.

Soundproof- International Maritime Organizations (IMO) have increased vessels’ acoustic performance requirements it guaranteeing the safety of marine operators and sailors. This makes sound insulation as important as thermal insulation in marine applications.

Weight-Unlike onshore applications, weight limits of marine insulation are a big consideration in shipping: between the amount of installed marine insulation and the combined weight of the entire vessels’ weight, there’s a strong, inverse relationship.

Naturally, there are many other factors to take into account during the selection of marine insulation materials. Generally speaking, rockwool marine thermal insulation is still the most popular choice. To know more about ECOIN marine insulation, please click: Ecoin Rock Wool Marine Offshore Insulation