Most thermal insulation materials have the property of sound insulation. The main parameters to measure the effect of acoustic insulation are STC ratings and NRC. During the selection of insulation materials for heat preservation, the sound insulation effect has become the second most important parameter, after the R-value of thermal insulation.

1. What is soundproof insulation?

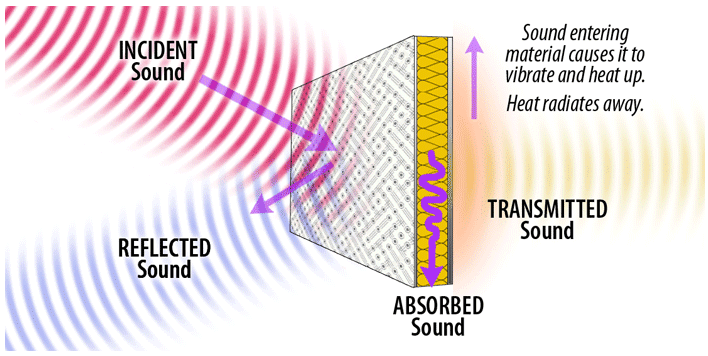

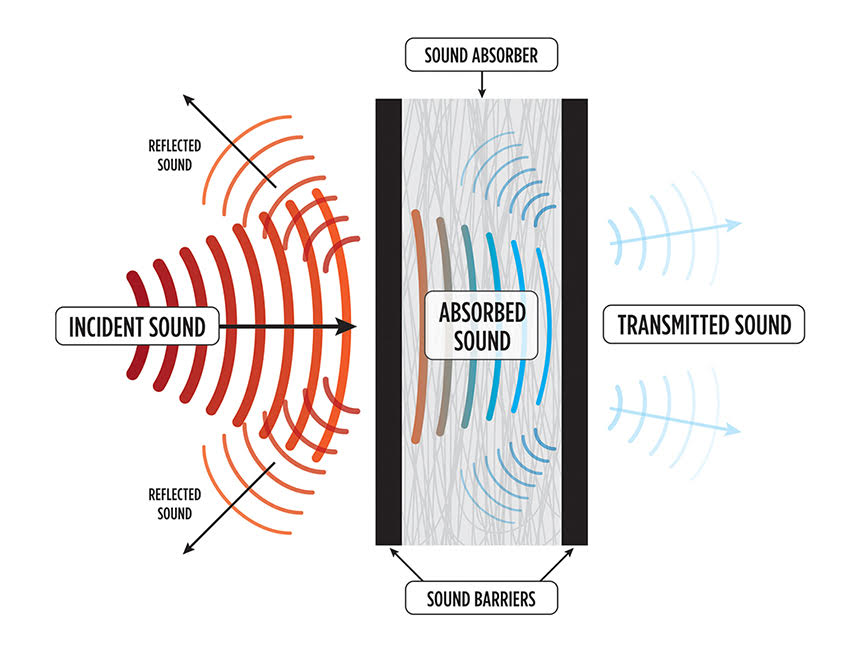

Soundproof insulation is a material used to block out or reduce the amount of sound energy. According to the National Insulation Association (NIA) in the United States, sound insulation is to “decouple” or separate the noise source from the rest of the structure. In other words, acoustic insulation refers to reducing the transfer of sound through the structure: generally speaking, there are three types of noise reduction methods, sound absorption, sound reflection, and sound diffusion.

Sound absorption is the most common type for soundproofing of insulation materials: once the sound wave passes through the insulation material, part of its energy will be trapped in the air pockets of the material; thus friction and viscosity resistance will convert a certain part of the sound energy into kinetic energy.

What are NRC and STC?

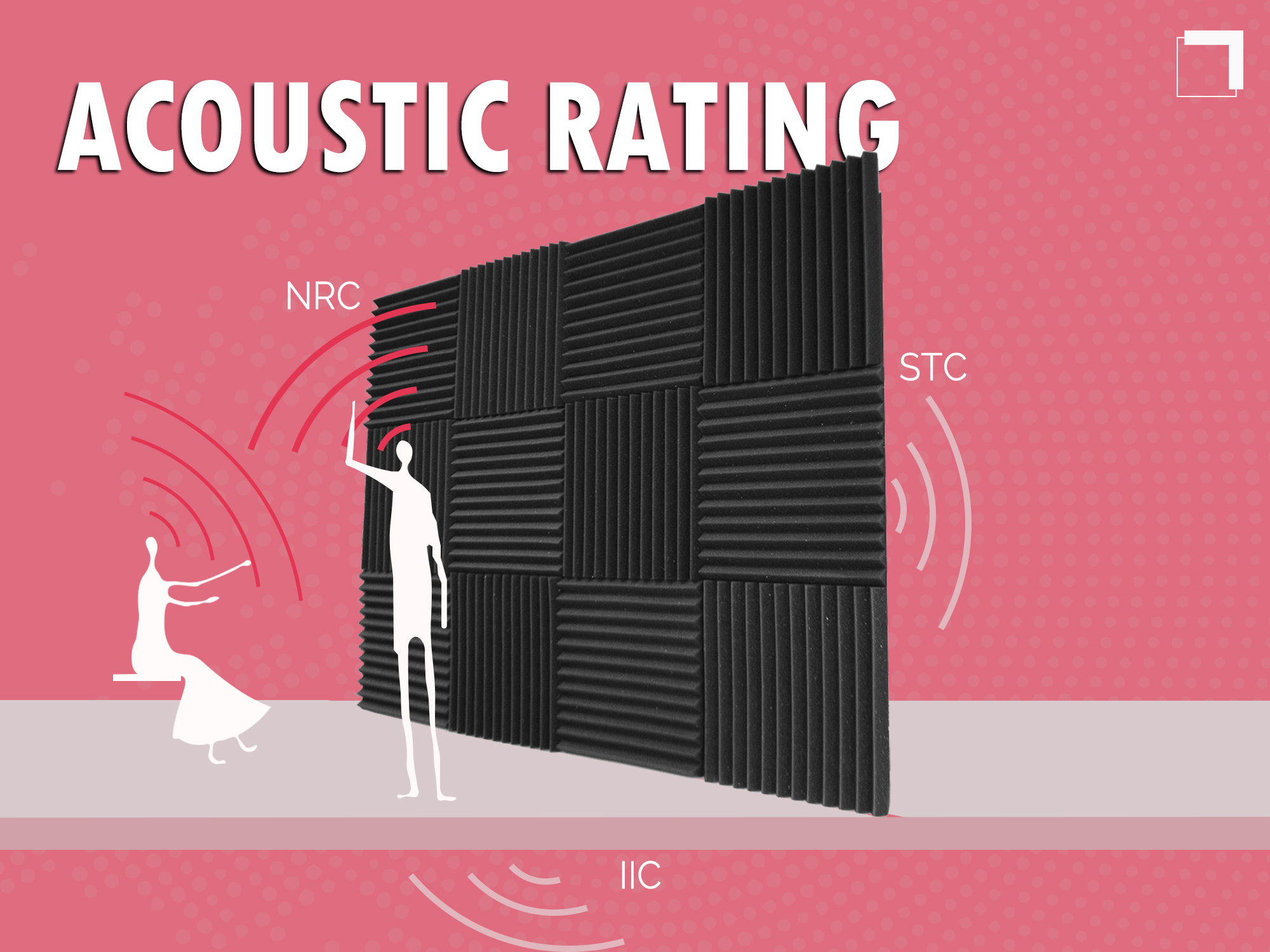

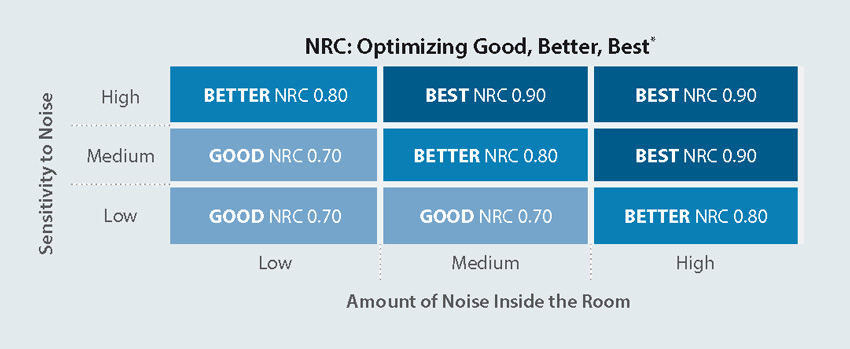

Noise Reduction Coefficient (NRC)

NRC stands for Noise Reduction Coefficient, which is a standard rating for how well a material absorbs sound at normal speech frequencies. This parameter is measured between zero and one: an NRC of 0 indicates perfect sound reflection; an NRC of 1 indicates perfect sound absorption. For example, if the NRC of soundproof fiberglass insulation is 0.82, then this material will absorb 82% of the sound that passes through and will reflect 18% of the sound back into the space.

It’s worth mentioning that this NRC value only indicates the average coefficient of the mid-frequency sound absorption and it doesn’t indicate the material’s absorptive ability at low or high sound frequencies. Besides, different materials with the same NRC may provide very different barrier effects.

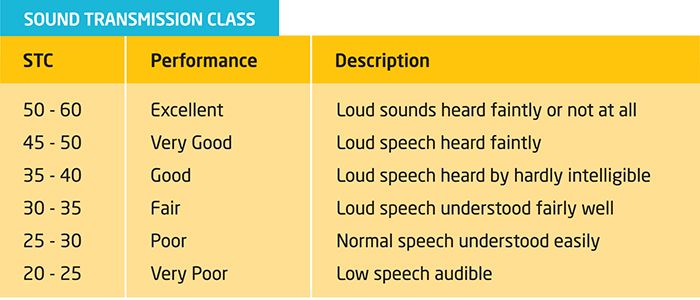

Sound Transmission Class (STC)

STC stands for Sound Transmission Class. This value is used to measure the transmission loss of airborne sound. Generally, this rating ranges from 25 to 65. The higher the rating, the more effective the material is at reducing sound transmission.

It’s worth mentioning that STC measures the sound transmission loss between 125 and 4000 Hz, which means that noises below 125 Hz can’t be measured by STC. However, many sound isolation complaints are from sound below 125 Hz.

2. Is thermal insulation material good for soundproofing?

Can we use thermal insulation material for soundproofing? This is a frequently asked question. Many people think that thermal insulation material and acoustic insulation can be used interchangeably. Actually, thermal insulation does prevent some noise and sound from passing through. However, insulation for soundproofing and thermal insulation are two different things: thermal insulation is used to block heat to enter or exit the house; even though it can prevent some noise to pass through, its soundproofing effect isn’t enough. This doesn’t mean that multiple-layered insulation for both head and sound is necessary on every occasion: there are still insulations available both for soundproofing and thermal proofing at the same time, thermal acoustic insulation.

Thermal acoustic insulation is used to block heat and sound at the same time: both fiberglass insulation and mineral wool are thermal acoustic insulation. These materials can be used for many purposes like military applications, commercial applications, and industries. For example, in vehicles or other industrial equipment, some product designs might fail to account for heat and noise, which might put the equipment and personnel at risk. Heat might damage some sensitive components such as GPS systems and noise make the whole process of driving or manipulating uncomfortable and unsafe.

On these occasions, thermal acoustic insulation is necessary.

3. How to select the best soundproof insulation materials?

Nowadays there are many different types of sound insulation materials on the market. How to select the best soundproof insulation materials? Here are some tips:

*STC rating and NRC rating of insulation

As we mentioned before, both the STC rating for insulation and the NRC value are important are essential indicators of the insulation material: NRC of insulation indicates the material’s ability to reduce the noise while STC of insulation indicates the transmission loss of the sound passing through the material; the higher the number the better is the material for acoustic insulation.

*Durability

Durability indicates the material’s sound insulation ability for a long duration of time.

The best sound insulation material renders a stable sound insulation effect as time goes by. For example, soundproof mineral wool has an unchangeable soundproofing ability as this material is made of inorganic fibers, which help to maintain its stability.

*Price of Insulation

Nowadays in the market, there are mainly three types of sound insulation materials: batts or roll insulation, blown-in insulation, and spray-foam insulation. Different types meet different demands and also determine different sound insulation effects.

Compared to blown-in insulation and foam spray insulation, batt or roll insulation is much cheaper. If you need to cover a wide and large area with acoustic insulation, batt or roll insulation might be a more economic choice.

However, if you’re considering filling the floor in a commercial building then blown-in insulation is your best choice.

ECOIN offers a great variety of thermal acoustic insulation and every type has its own properties and advantages. Our main products are the following:

Soundproof fiberglass insulation

Our Soundproof fiberglass insulation offers a good sound barrier by absorbing the sound wave. Actually, fiberglass insulation might be the best material for soundproofing.

Our soundproof fiberglass insulation is widely used in business buildings where there is lot of chatter, phone calls, and corporate meetings. The fiberglass insulation helps to reduce the noise by more than 5 decibels.

It’s worth mentioning that soundproof fiberglass insulation works by sound absorption not by sound blocking. For this reason, the fiberglass isn’t capable of doing a complete blockage of the noise. Anyway, the fiberglass layer is usually just a few inches thick and you can’t expect wonders from it.

For more information, please click: Ecoin Fiberglass insulation

Soundproof mineral wool insulation

Like soundproof fiberglass insulation, our soundproof mineral wool insulation is also characterized by a porous structure, which helps to trap the sound wave. Besides, the soundproof mineral wool insulation damps the vibrations emanating from airports, trains, and other sources. This also helps to reduce the noise.

Compared with fiberglass wool, rock wool is more durable and less prone to degradation over time. This helps to maintain its soundproofing ability more stable. Besides, rock wool is a breathable material, which means it has excellent ventilation properties prohibiting the growth of mold. On the other hand, the fiberglass wool isn’t breathable, which doesn’t only jeopardize the personnel’s health but also attracts mold, which reduces its insulation ability.

For more information, please click: Ecoin Rock Wool

Soundproof foam rubber

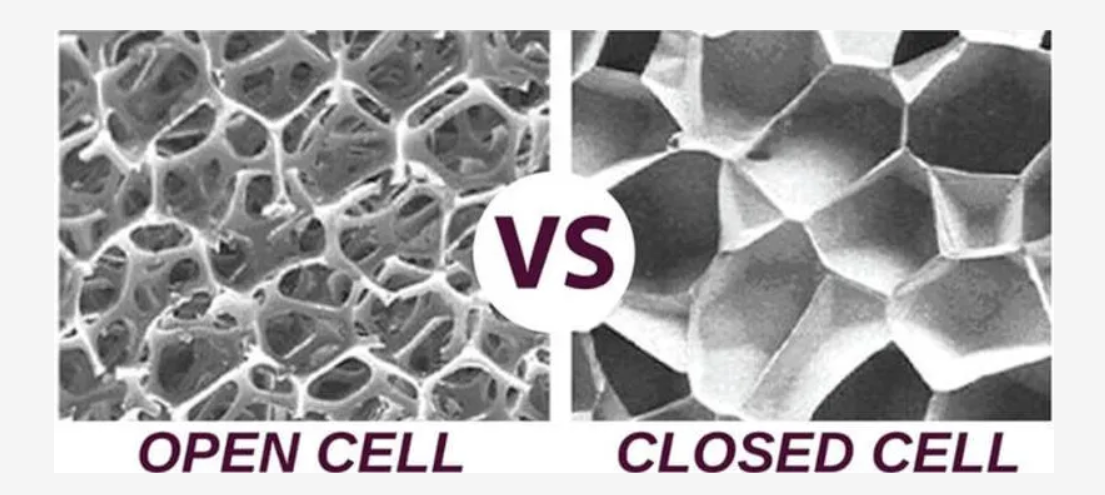

First of all, it’s necessary to clarify this conception: foam rubber doesn’t block the sound wave; it absorbs the sound energy. To understand how the soundproof foam rubber reduces sound, it’s important to learn the two different structures of the material:

Open-cell foam is characterized by porous spots. Once the sound wave moves through the material, the foam rubber will absorb the sound by retaining it in its open call chambers. However, these cell chambers of irregular shape can’t provide the users stable control over the level of sound energy absorbed. This makes the open-cell soundproof foam rubber suitable for absorbing mid- and high-frequency sounds.

Closed-cell foam is characterized by tightly woven cells that provide a “closed” effect to the sound wave. The close-cell soundproof foam rubber works better at absorbing low-frequency noise.

For more information, please click: Ecoin Rubber Foam