1. What are insulation accessories?

The insulation accessories are fasteners or tools used to install insulation materials. There’s a wide range of insulation accessories, including support materials, sealants, adhesives, tapes, etc. All these insulation materials are used to secure the installation of insulation and improve insulation efficiency.

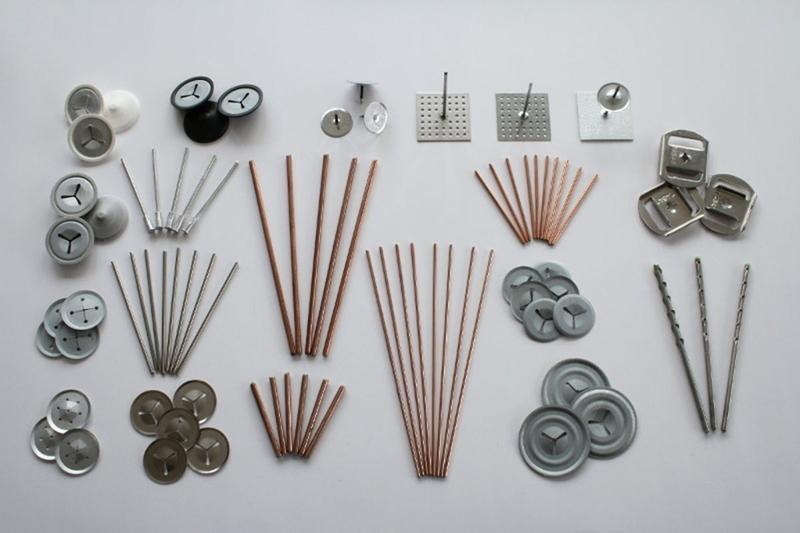

ECOIN insulation accessories vary in materials, forms and applications: we mainly offer insulation pins and washers, stainless steel strapping, aluminum foil tape, and aluminum elbow. All ECOIN insulation accessories have one thing in common, which is to ensure that your projects are completed successfully.

2. How to use insulation pins?

2.1 What are insulation pins?

Insulation Pins, also known as insulation hangers, are the most commonly used fasteners to mechanically fix and install insulation material. Moreover, this insulation material should be the types that can be pierced by metal spindles, such as fiberglass wool, rock wool insulation, etc.

Basically, there are two types of insulation pins: the stud-weldable insulation pin and the non-weldable insulation hangers, which are designed to be bonded with adhesive. And in terms of these adhesive insulation pins, there are two categories: the self-adhesive pins for insulation and the perforated insulation pins.

2.2 Different types of insulation pins and how to install them?

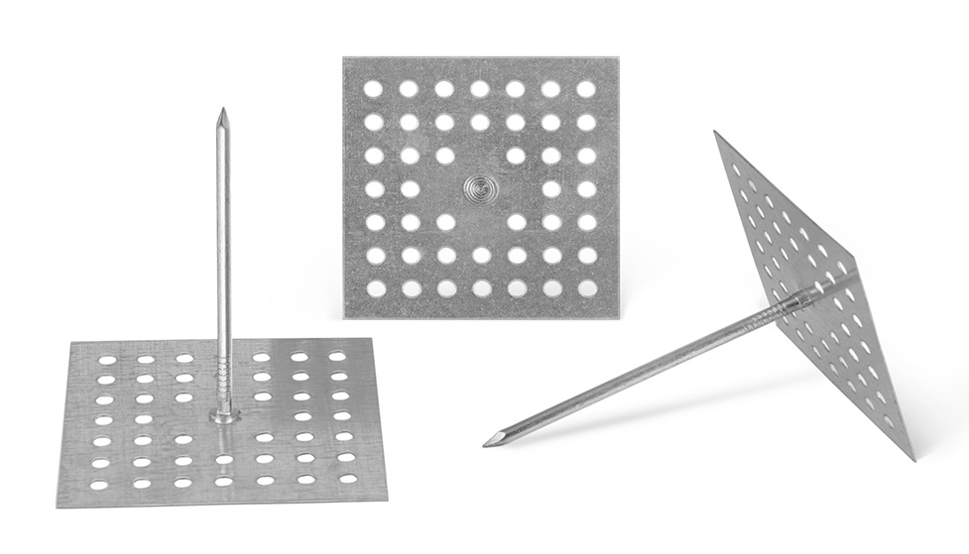

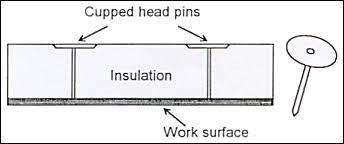

Perforated Base Insulation Hanger

The Perforated Base Insulation Hanger is made from mild steel. Its main structure is a perforated metal base with a vertical pin attached. The metal base of this insulation hanger is perforated with nail-sized holes, which are designed for use with adhesive: this adhesive is applied to the back of the pin base; when the pin is pressed against the wall or the ceiling, the adhesive will come through the penetrations creating a solid bond. The pin on the metal base is used for impaling and installing various insulation materials. Besides, a self-locking washer is required to place onto this perforated base insulation hanger, securing the insulation pin in place.

Normally the metal base of the perforated base insulation hanger is 2″ x 2″ and the diameter of the pin is 0.015 inches. In terms of the length of the pin, we offer various sizes to meet your demand.

Installation tips:

While sticking the insulation pin onto the wall or ceiling, make sure to allow the adhesive to dry thoroughly before hanging the insulation. This drying time varies with temperature and type of adhesive. Generally, it takes 24-72 hours

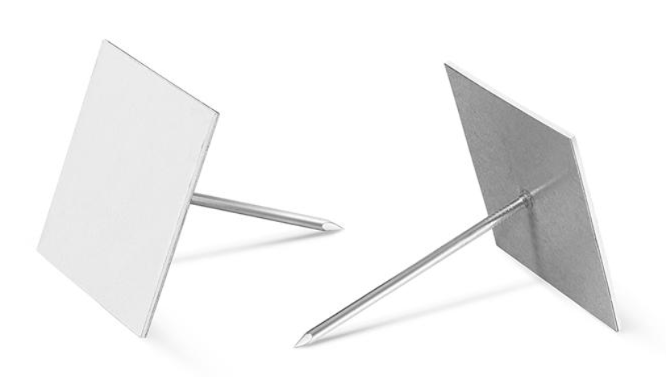

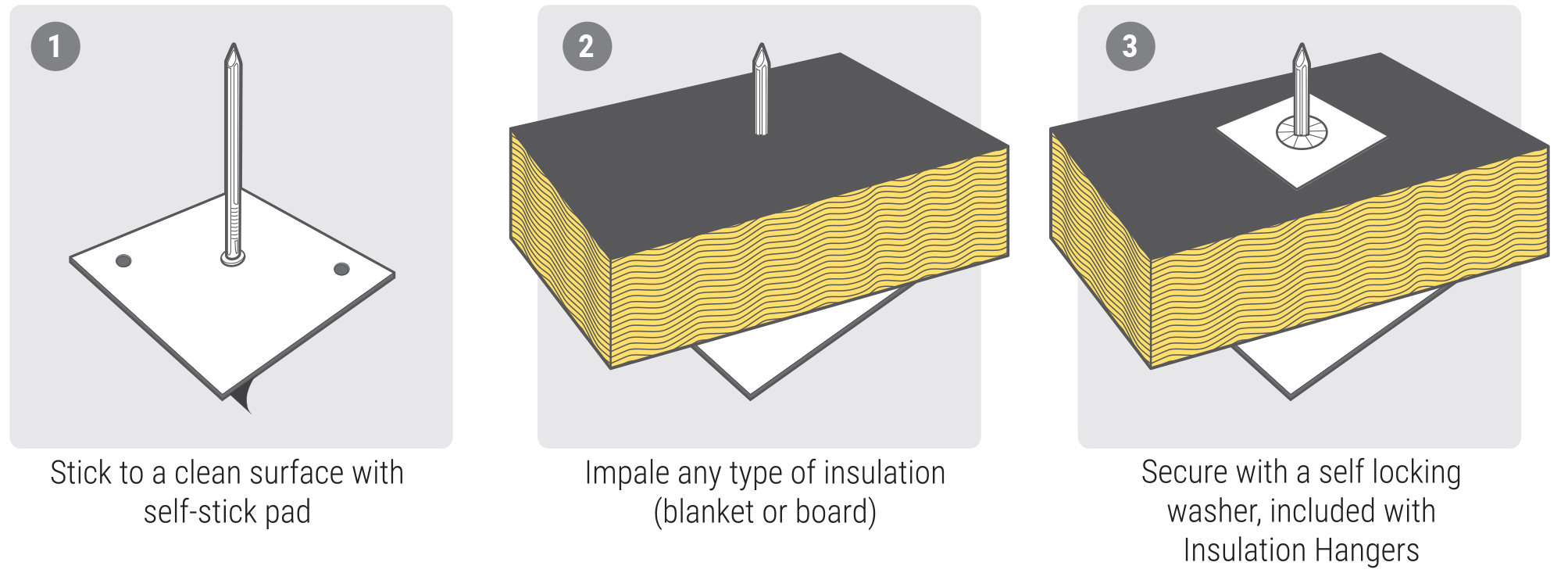

Self Adhesive Insulation Pins

Self Adhesive Insulation Pin, also known as a self-sticking insulation hanger, is another kind of insulation pin with a foam adhesive on the bottom of its metal base. This foam adhesive is covered with wax release paper.

This self-adhesive pin for insulation is used to fix insulation materials on vertical, smooth clean, and dry surfaces. Once the insulation material is pierced onto the pin, a locking washer or a domed cap is required to hold the insulation hanger in place.

Installation tips:

Like the perforated base insulation hanger, this self-adhesive pin for insulation also requires time to dry thoroughly: allow the pin to stand for 15-20 minutes. Normally, the sticker reaches its expected resistance level after 12 hours. Besides, the load limit for the per hanger is 2-3lb at maximum.

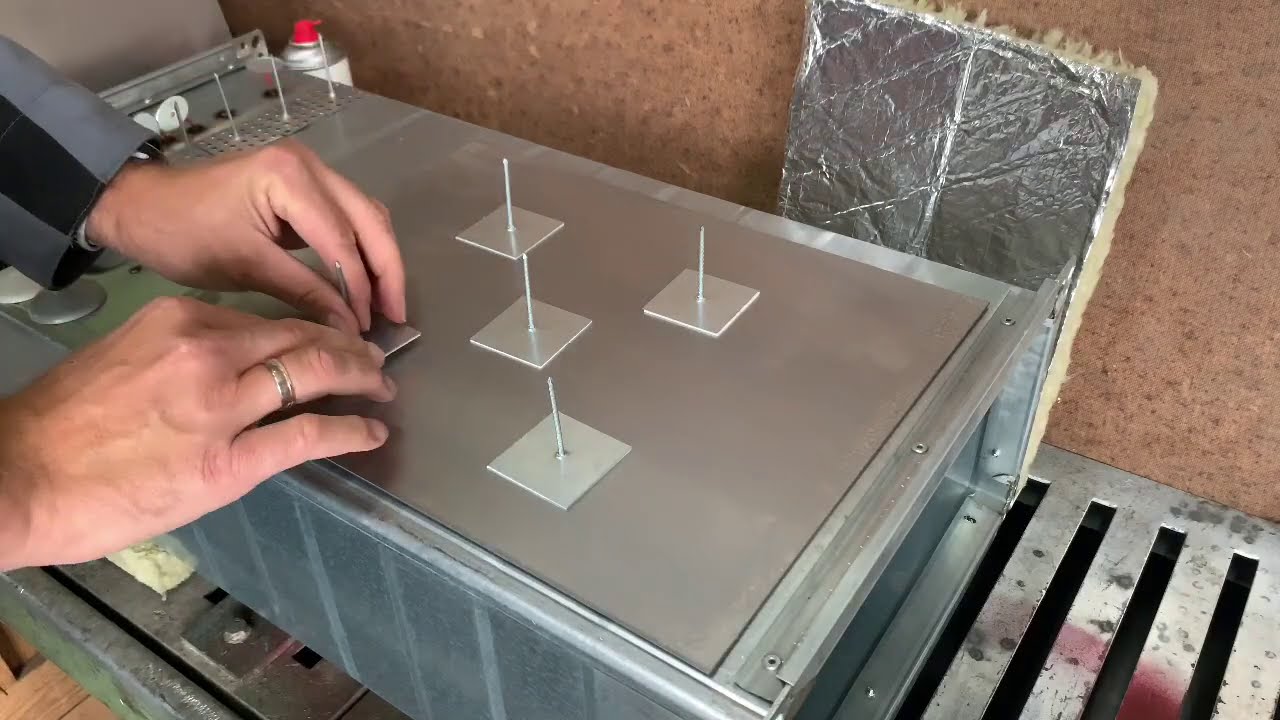

Weld Pins for Insulation

Unlike the perforated insulation pins or the self-adhesive pins for insulation, which are jointed to the surface by adhesive, the weld pins for insulation are applied with welding equipment. Like other types of insulation pins, this weld pin also requires a locking washer to hold the insulation material in place.

Installation tips:

Unlike the self-adhesive pins for insulation or the perforated insulation pins, this weld pin has no specific requirements in terms of temperature.

3. How to use stainless steel strapping and banding for insulation?

The Stainless Steel Strapping (stainless steel banding) is an ideal choice for bundling and fastening applications, in particular the applications involving corrosive environments. For this reason, stainless steel strapping is widely used in oil and gas industry, marine applications, etc.

Among ECOIN insulation accessories, the stainless steel strapping is a star product for insulation and jacketing. Our clients are mainly from the industrial, commercial, governmental, and marine sectors.

3.1 What is stainless steel strapping/banding?

The Stainless Steel strapping is a band of stainless steel in grades 304, 316, or 201. Generally speaking, this stainless steel banding is used for firmly holding loose loads.

This 316 stainless steel strapping or 304 stainless steel strapping is the best choice for pipe insulation: once the pipelines and the insulation materials are held in place, the metal jacketing is required to secure and protect the insulation; however the normal fasteners such as screws or rivets might damage the insulation and for this reason, the stainless steel banding is appropriate. Both the 304 stainless steel strapping and the 316 stainless steel strapping are highly resistant to corrosions securing the pipeline insulation.

In the process of this stainless steel banding, there are three major steps: securing, tightening and cutting. In the process of securing, the loose items are held together by the stainless steel strapping; in the second stage, the stainless steel strapping will be tightened by a steel banding tensioner; in the last step, the stainless steel strapping will be locked by stainless steel banding buckles and the unwanted ends will be cut.

It’s worth mentioning that stainless steel banding buckles are indispensable in stainless steel banding. ECOIN offers different types of buckles, such as stainless steel wing seals, etc.

3.2 What is the difference between stainless steel banding and aluminum foil tape?

Unlike the stainless steel strapping that holds the loose loads together, aluminum foil tape is commonly used to secure duct seams, connections, and joints. Aluminum foil tape is mainly made with aluminum, but some aluminum foil tapes also contain fiberglass or other materials, which makes the aluminum foil tape more durable and highly resistant to water and other corrosions.

The aluminum foil tape is characterized by its high resistance to moisture, chemical corrosion and flame, good heat and light reflectance, and high flexibility. All these features make the aluminum foil tape an ideal choice to secure the duct seams and prevent leakage. Besides the aluminum foil tape also resists the UV degradation. All mentioned above help to protect the insulation materials on the pipeline improving the insulation efficiency.

As a professional aluminum foil tape supplier, ECOIN doesn’t only offer regular aluminum foil tape, but also many other kinds to meet your demand, such as fiberglass aluminum foil tape or reinforced aluminum foil tape, which offers higher durability.

4. What is an aluminum elbow for pipe insulation?

The Aluminum Elbow Cover is widely used to protect the pipe insulation: it can be installed at every angle or bend in a pipeline, over the aluminum metal jacketing. Normally, the interior of the aluminum elbow is coated with a moisture barrier to prevent electrolytic degradation; and the outside of the aluminum elbow is coated with an acrylic acid layer or polyester fiber coating to prevent the pipe insulation from other corrosions. This aluminum elbow can be secured by stainless steel strapping, drill screws or rivets.

ECOIN offer both smooth and stucco embossed aluminum elbow cover.